If you’re considering an upgrade to the lighting in your industrial or commercial facility, a crucial factor to consider is the high bay lights price. Before you can understand the pricing, it’s essential to delve into the elements of high bay lights that determine their costs.

Table of Contents

The Role of Raw Materials in Determining High Bay Lights Price

When it comes to the pricing of high bay lights, a crucial component to consider is the cost of the raw materials. What makes one high bay light pricier than others? The devil is in the details – quality raw materials play a definitive role.

Let’s delve into specifics. High bay lights are LED lamps, and the cost of the LED chips significantly influences their pricing. Top-quality manufacturers like Cree, Lumileds and Seoul typically command a higher price due to their reputable performance, consistency, and longevity.

Another key raw material in high bay lights is the driver, which controls the power going into the LED chips. A higher-quality driver like those from Meanwell ensures better performance and longevity for the light. Consequently, the better the driver, the higher the price.

The materials used for the light’s housing also contribute to the cost. Durable, heat-dissipating materials such as aluminum are typically more expensive than plastic. They play a significant role in ensuring the lamp operates effectively and increases luminous efficacy.

Lastly, the optics used in LED high bay lights can elevate the price. Well-designed optics ensure that light is distributed evenly and efficiently. They also contribute to luminous efficiency, reducing energy consumption and saving money over time.

In conclusion, while initial costs may be higher due to superior raw materials, in the long run, investing in quality means fewer replacements, less maintenance, and considerable energy savings. It’s a case of ‘Buy well, cry once’. Be aware of the role of different raw materials in determining the high bay lights price to make an informed investment.

The Impact of Different Types of LED Drivers on High Bay Lights Pricing

The heart of LED High Bay Lights

When it comes to pricing LED high bay lights, the LED drivers play a key role. Think of them as the heart of the lamp, pumping energy to the LED to keep it glowing. The price tag can fluctuate based on the type, quality, and lifespan of the LED driver used.

- SELV Drivers: SELV (Safety Extra Low Voltage) drivers are designed to operate at a low voltage, reducing the risk of electric shock. SELV drivers comply with strict safety standards and offer excellent protection against electrical hazards. Although they are typically more expensive due to their safety features, their reliability and compliance with regulations make them a preferred choice for ensuring user safety and peace of mind.

- Non-SELV Drivers: Non-SELV drivers operate at higher voltages compared to SELV drivers and are suitable for applications where safety is not the primary concern. These drivers are often more affordable and can handle higher power outputs, making them ideal for industrial and commercial settings. While they offer good performance and value, they require careful installation and proper insulation to mitigate the risk of electric shock. Non-SELV drivers are a practical choice for environments where stringent safety measures are not necessary.

- DOB Drivers: DOB (Driver on Board) drivers integrate the driver circuitry directly onto the LED board, resulting in a compact and streamlined design. This integration reduces the number of components needed, making them cost-effective and easier to assemble. However, DOB drivers can generate more heat and may have a shorter lifespan due to their compact nature. They are suitable for applications where space is limited and cost savings are important, but they may require additional heat management solutions to ensure long-term reliability.

| Item | DOB | Non-SELV | SELV |

|---|---|---|---|

| Price | ★★ | ★★★ | ★★★★★ |

| Heat Dissipation Performance | ★★★ | ★★★★★ | ★★★★★ |

| Safety | ★★★ | ★★★★ | ★★★★★ |

| Light Efficiency | ★★★★★ | ★★★★★ | ★★★★ |

| Lifetime | ★★★ | ★★★★★ | ★★★★★ |

Pros and Cons of Different Types LED High Bay Lights

Checking the Quality of LED drivers

The quality of LED drivers significantly affects the high bay lights price. More reliable, high-quality drivers such as those from Meanwell, Philips, or other top-tier brands tend to be pricier but are worth the price for their efficiency, longevity, and safety certifications.

Evaluating the Lifespan

In terms of lifespan, the electrolytic capacitor’s endurance at high temperatures is a key part of LED driver quality. Quality drivers have a long-rated lifespan, typically between 50,000 to 100,000 hours, which can help save replacement costs in the long term.

Finally, let’s not forget about the brand premium when it comes to LED drivers. Trusted, stamped brands may drive up the high bay lights price more than lesser-known labels, but they also come with a level of reliability and assurance of quality that is often worth the extra investment. If you’re not sure what type or brand of LED driver you need for your high bay lights, don’t hesitate to contact us.

Product Quality and its Effect on High Bay Lights Price

The quality of a product often directly correlates with its price, and high bay lights are no exception. When it comes to LED High Bay Lights, various elements contribute to the overall quality, thus dictating the resultant price. Here’s how.

LED Chips Quality

The heart of any LED fixture is the LED chip, responsible for transforming electrical energy into light. The quality of these chips impacts both the light efficiency and lifespan of the LED fixture. Superior LED chips come at a higher cost but offer better reliability and performance.

Quality of Materials and Heat Dissipation

High-quality materials used in LED high bay light construction, such as robust housing materials and superior-quality diffusers, add to product durability. For instance, some models will employ aluminum for its excellent heat dissipation properties, positively impacting LED s’ lifespan and thus, price. Alternatively, more budget-friendly options may use less expensive materials, but with trade-offs in performance and longevity.

Certification Compliance

Adherence to international standards and certifications also significantly impacts the cost of LED high bay lights. Certifications such as those awarded by the American National Standards Institute(ANSI) or IECEE CB, CE, ensure that you have a product that meets high safety and performance benchmarks. LED light fixtures carrying these certifications might demand a higher price point, but for a good reason – they promise quality, reliability, and peace of mind.

Warranty

Last but not least, the warranty period offered by the manufacturer could impact the overall cost of the LED high bay light. Higher-priced products often come with more extended warranty coverage, providing assurance about the product’s long-term performance and saving potential maintenance costs down the line.

In conclusion, the product quality directly impacts the LED High Bay Light’s price. While it is tempting to go for the lowest-priced option, it is important to consider these elements of quality that are worth investing in for long-term benefits and cost savings. Still, feeling unsure? Don’t fret! Reach out to us and let’s make the most out of your investment together.

Labor Cost, Rental Cost, and Other Operational Expenses in LED High Bay Lights Price

The manufacturing process of LED High Bay Lights has an extended series of steps, each requiring skilled labor, quality machinery, and the right facilities. This process significantly impacts the final cost of the product.

Labor Costs

The process of manufacturing LED lights requires a considerable amount of precision and skill. It is not just a matter of assembling different parts; it involves careful checking of each component’s quality and cautiously placing them in the right order. Even with the latest machinery, the process still requires manual labor, and the labor costs can directly reflect on the cost of the lights.

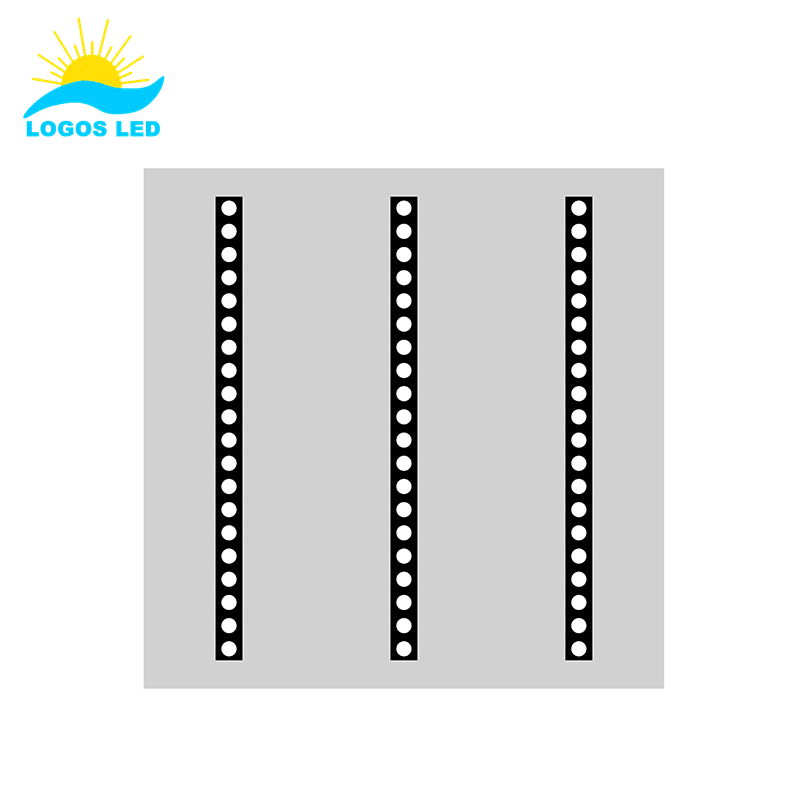

LED High Bay Light Assembly Process

Rental Costs

Manufacturers also have to handle rental costs, and maintain their factories, warehouses, and offices. The factory’s location has a significant effect on the rental cost, influencing the price of the LED High Bay lights. Companies located in regions with high real estate prices have to adjust their pricing accordingly to cover these costs.

Operational Expenses

There are many other operational costs a manufacturer needs to account for in final pricing. These include utilities like electricity and water, maintenance for machinery, transportation and logistics for raw materials and finished products, and various administrative expenses like taxes and legal fees.

Understanding these components will help you realize why two products, seemingly identical, can have such significant price differences. It’s advisable not to jump for the cheaper option, as it may have underlying issues, leading to more costs in the long run. If you have any doubts regarding your LED lighting options, don’t hesitate to reach out to us for guidance.

The Influence of Sales Channels on the Price of High Bay Lights

When entering the market to purchase LED high bay lights, it’s crucial to realize that the pathway you choose to navigate through this mission could significantly influence the high bay lights price. The higher-end product price in physical stores often reflects the embedded costs of rental space, utility bills, employee wages, and a multitude of other operational expenses. Consequently, offline retail prices are often considerably higher than online platform prices.

On the contrary, online platforms can often operate with fewer overhead costs, leading to more competitive pricing. Online sales channels like B2B platforms, e-commerce websites, or direct brand websites leverage the power of the internet to cut down on physical infrastructure expenses. They also provide customers with a convenient, easy-to-navigate experience and a wealth of information on LED Lighting choices.

Brand Premium and High Bay Lights Price: A Deep Dive

In the world of high bay lights, your brand choice might significantly affect the overall pricing. This concept is widely known as “brand premium”. Essentially, a brand premium is the extra amount of money consumers are willing to pay for a well-known and trusted brand compared to a less-known brand of equal quality. For instance, consumers will more likely pay a higher price for brands such as Philips Lighting or General Electric due to their established reputation, even if similar products from less-known brands are cheaper.

In the context of LED High Bay Lights, reputability, expertise, and customer experience—core factors that largely build a brand—are often reflected in pricing. Consumers tend to perceive that renowned brands provide superior quality, customer service, and warranties that justify a higher price. These brands have invested significant resources over the years to gain customers’ confidence which in turn, allows them to charge a brand premium.

Tips on Choosing the Perfect LED High Bay Lights for Your Needs

Trying to find the perfect LED high bay lights can feel like trekking through a jungle of technical jargon and confusing specifications. But worry not, this guide will help you navigate this task with ease!

Understand Your Lighting Requirements

Start by understanding your specific lighting needs. This involves evaluating the area size, height, and the type of work performed in the space. For example, an assembly line might require brighter illumination compared to a storage area. You can refer to the guidelines for different tasks: Illuminate Your Workspace: A Comprehensive Guide To High Bay Industrial Lighting

Consider the Colour Temperature

The color temperature of a light source can affect the apparent brightness and mood of a space. Think about the color temperature best suited for your workspace. High bay lights in cool white (5000K to 6000K) simulate daylight and are ideal for detailed tasks. You can learn more on Different Color Temperature to make an informed decision.

Check for Energy Efficiency

LED lights are known for their energy efficiency, but not all LED lights are created equal. You can compare the luminous efficacy of different lights, a measure of how well a light source produces visible light, to find the most efficient option.

Look for Quality Products

Investing in high-quality products might require a higher initial investment, but it will save you money in the long run with lower replacement and maintenance costs.

Factor in Installation and Maintenance Costs

Remember, the sticker price is just the beginning. Consider the costs of installation, and how easy it will be to maintain or replace the lights if necessary.

Feel overwhelmed? Reach out to us for personalized advice and recommendations for your lighting needs!

Conclusion

Choosing the right LED high bay light is guided by several factors including quality of raw materials, product quality, and costs of labor and rent. Branding and sales channels also significantly dictate the prices. Understanding the different types of LED chips, drivers, and heat sinks contributes to making more informed decisions. In doing so, we not only consider the cost but also the luminous efficacy and subsequent savings. So, let’s embrace the LED light revolution armed with the right knowledge for better choices. Reach out to us if you wish to learn more.

Request A Free Quote Now!

Send us a message if you have any questions or request a quote. We will get back to you ASAP!

Leave a Reply

Your email is safe with us.