Poor factory lighting can wreck efficiency, increase mistakes, and lead to workplace accidents. When workers struggle to see clearly, they get fatigued, make more errors, and face higher safety risks. The right factory lighting doesn’t just brighten up the space—it boosts safety, improves productivity, and keeps operations running smoothly.

Picking the best lighting for a factory isn’t just about choosing bright fixtures. It’s about meeting safety standards (like EN 12464-1 and OSHA), optimizing efficiency, and reducing costs. You need to consider factors like lux levels, ceiling height, fixture types, and lighting controls. High bay lights are best for tall ceilings, while low bay lights work for lower spaces. CRI (Color Rendering Index) and color temperature impact visibility, and smart controls help cut energy use. Plus, emergency lighting is a must for safety.

If you want better performance, lower costs, and a safer work environment, the right LED lighting makes all the difference. Let’s break down the key types, benefits, and factors to consider when choosing factory lighting.

Table of Contents

What is Factory Lighting?

Factory lighting is designed to handle large industrial spaces, harsh conditions, and high-efficiency demands. It provides powerful, even illumination that enhances worker safety and productivity while meeting energy-saving standards.

Key Features of Factory Lighting

- High Brightness & Uniformity – Bright, even lighting reduces eye strain and improves work accuracy.

- Durability & Resistance – Built to withstand dust, moisture, chemicals, and extreme temperatures.

- Energy Efficiency – LEDs cut energy use while delivering high lumen output.

- Long Lifespan – Most industrial LEDs last over 50,000 hours, reducing maintenance costs.

- Customizable Options – Dimmable, motion-sensing, and smart control systems help optimize energy use.

What Kind of Lighting is Used in Factories?

Factories need different lighting types depending on the ceiling height, layout, and work requirements. Let’s go over the most common options.

1. LED High Bay Lights

- Perfect for factories with ceilings over 20 feet.

- Provides powerful, widespread illumination with minimal glare.

- High lumen output and excellent energy efficiency.

- Available in various beam angles to fit different applications.

2. LED Linear Lights

- Best for assembly lines, workstations, and warehouse aisles.

- Delivers uniform lighting across large horizontal spaces.

- Can be suspended or surface-mounted, depending on the setup.

- Available in linkable modules for extended coverage.

3. Explosion-Proof LED Lights

- Built for hazardous environments with flammable gases, dust, or vapors.

- Features reinforced housing to prevent sparks.

- Used in chemical plants, oil refineries, and paint factories.

4. LED Floodlights

- Provides high-intensity, broad coverage for large areas.

- Ideal for outdoor security, loading docks, and factory perimeters.

- Comes with high IP ratings for dust and water resistance.

5. LED Vapor Lights

- Designed for factories with high humidity, dust, or exposure to chemicals.

- Waterproof and dustproof for long-lasting durability.

- Common in parking garages, food processing plants, and cold storage.

6. LED Tube Lights

- Energy-efficient replacement for traditional fluorescent tubes.

- Delivers consistent lighting with minimal glare.

- Commonly used in hallways, general factory areas, and offices.

7. LED Panel Lights

- Best for office spaces, meeting rooms, and quality control areas.

- Provides low-glare, uniform lighting for indoor environments.

- Can be recessed, surface-mounted, or suspended for a sleek look.

8. Task Lighting

- Focused lighting for detailed work areas.

- Common in assembly lines, inspection stations, and precision workstations.

- Available in adjustable or fixed designs, depending on the task.

Each type of lighting serves a specific role in keeping your factory safe, productive, and energy-efficient. Choosing the right mix ensures your team can work comfortably while reducing unnecessary costs.

What is the Lighting Standard for a Factory?

Factory lighting needs to meet strict standards to ensure safety, efficiency, and worker productivity. These standards define the minimum lux levels, color rendering, glare control, and uniformity required for different factory areas.

1. Recommended Illumination Levels (Lux)

Factory lighting brightness is measured in lux (lumens per square meter). Here’s a breakdown of recommended levels for different areas:

| Factory Area | Recommended Lux Level |

|---|---|

| General factory floor | 200-300 lux |

| Precision assembly | 750-1,500 lux |

| Heavy manufacturing | 300-500 lux |

| Packing & inspection stations | 500-1,000 lux |

| Warehouses & storage areas | 100-200 lux |

| Offices & control rooms | 500-750 lux |

2. Color Rendering Index (CRI)

- CRI measures how accurately colors appear under artificial light.

- CRI 80+ is recommended for general factory tasks.

- CRI 90+ is ideal for precision assembly, color inspection, and quality control.

3. Uniformity Ratio

- Lighting should be evenly distributed to eliminate shadows and glare.

- Recommended uniformity: 0.6 or higher (U0 = Minimum Lux / Average Lux).

4. Glare Control (UGR – Unified Glare Rating)

- Too much glare causes eye strain and reduces worker focus.

- UGR should be ≤ 22 for general factory work.

- UGR ≤ 19 for precision assembly and inspection tasks.

5. Energy Efficiency & Standards

- LED lighting is the best option for energy savings and durability.

- Must comply with ISO 8995-1 (CIE S 008/E:2001) for workplace lighting.

- Should meet or exceed energy codes like EN 12464-1 (Europe) and OSHA (USA).

6. Special Considerations

- High ceilings: LED high bay lights with narrow or wide beam angles work best.

- Dusty or humid environments: Use IP65/IP66-rated LED vapor lights or high bay lights.

- Hazardous locations: Explosion-proof lighting is required in chemical plants and oil refineries.

- Emergency lighting: Must comply with NFPA 101 (Life Safety Code) for proper exit and safety lighting.

Proper factory lighting improves safety, efficiency, and compliance with regulations. To get the best results, focus on lux levels, CRI, uniformity, glare control, and energy efficiency when designing your lighting system.

Benefits of LED Lighting in a Factory

Switching to LED lighting in factories offers huge advantages in energy efficiency, safety, and cost savings. Compared to older lighting like fluorescent, metal halide, and incandescent bulbs, LEDs are the clear winner for reliability and long-term performance.

1. Energy Efficiency

- Uses up to 80% less energy than traditional lighting.

- Delivers more brightness with less power (high lumen-per-watt efficiency).

- Lowers electricity costs and reduces the factory’s carbon footprint.

2. Long Lifespan

- LEDs last 50,000 – 100,000 hours, far longer than traditional bulbs.

- Cuts down on maintenance and replacement costs.

3. Improved Safety

- Instant-on lighting improves visibility and prevents accidents.

- Low heat emission reduces fire risks compared to HID or halogen lamps.

- No mercury or hazardous chemicals, making LEDs an eco-friendly choice.

4. Better Light Quality

- High CRI (80+ for general use, 90+ for precision work) ensures accurate color rendering.

- Flicker-free lighting prevents eye strain and fatigue.

- Available in different color temperatures (3000K-6500K) to match work environments.

5. Increased Productivity

- Even light distribution reduces glare and shadows.

- Enhances focus and accuracy, especially in assembly and inspection areas.

- Creates a more comfortable and productive workspace.

6. Lower Maintenance Costs

- LEDs require little to no maintenance due to their long lifespan.

- No ballasts, frequent bulb changes, or costly servicing.

- Ideal for hard-to-reach areas like high ceilings where maintenance is difficult.

7. Smart & Customizable Features

- Dimmable LEDs allow adjustable lighting for different tasks.

- Motion sensors and daylight controls reduce energy waste.

- Can be integrated with factory automation systems for efficiency.

8. Eco-Friendly & Compliance

- Contains no toxic chemicals (unlike fluorescent tubes with mercury).

- Reduces CO₂ emissions, making factories more sustainable.

- Meets global energy and safety standards like EN 12464-1 (Europe) and OSHA (USA).

9. Built for Harsh Environments

- IP65/IP66-rated fixtures withstand dust, moisture, and tough conditions.

- Explosion-proof LEDs improve safety in high-risk areas (e.g., chemical plants).

- High bay and vapor-proof LEDs work well in warehouses, production lines, and cold storage.

10. Long-Term Cost Savings

- While LEDs have a higher upfront cost, they quickly pay for themselves through:

- Lower energy bills

- Minimal maintenance costs

- Improved worker efficiency

Upgrading to LED factory lighting cuts costs, boosts safety, and enhances productivity. With a long lifespan, energy efficiency, and superior light quality, LEDs are the best investment for modern industrial lighting.

Factors to Consider When Choosing Factory Lighting

Picking the right factory lighting isn’t just about making the place brighter—it’s about safety, efficiency, and productivity. The right setup can reduce energy costs, improve working conditions, and ensure compliance with industrial lighting standards. Here’s what you need to consider:

1. Industrial Lighting Standards

Factory lighting must meet regulations like:

- EN 12464-1 (Europe)

- OSHA (USA)

- ISO 8995-1 (CIE S 008/E:2001)

Recommended lux levels vary by work area:

- 200-300 lux for general factory floors

- 500-1,500 lux for precision workstations

- 100-200 lux for warehouses and storage areas

Glare control (UGR ≤ 22) and uniformity (U0 ≥ 0.6) are also crucial for worker comfort.

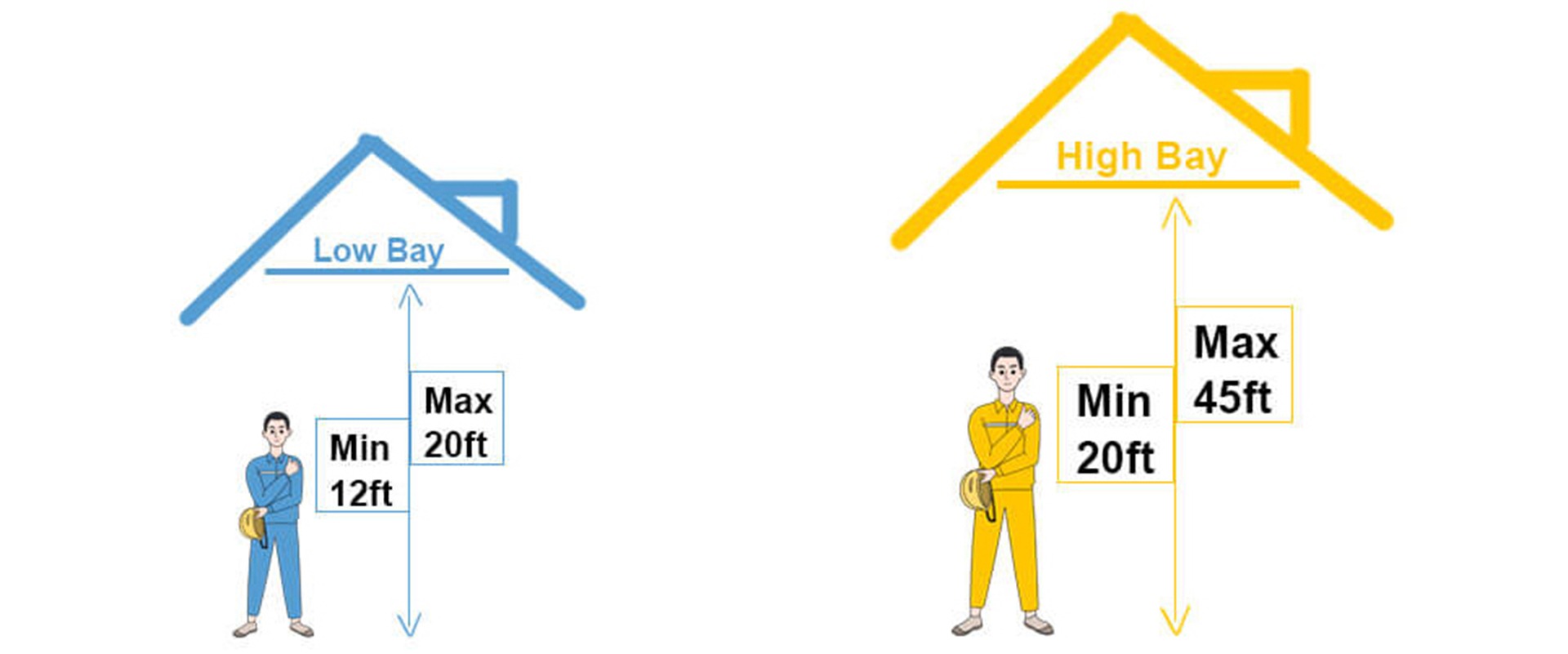

2. Ceiling Height

- Low ceilings (≤20ft): Use LED low bay lights, linear lights, or vapor-proof lights.

- High ceilings (20ft-40ft): Install LED high bay lights with the right beam angle.

- Very high ceilings (40ft+): Go for high-power LED high mast lights for even coverage.

low bay vs high bay light

3. Lighting Requirements

- General Illumination: Even lighting across the workspace using LED high bay or linear lights.

- Task Lighting: Focused illumination for assembly lines, inspection stations, or quality control areas.

- Outdoor & Security Lighting: LED floodlights and streetlights for safety.

- Hazardous Areas: Explosion-proof LED lights for chemical plants or flammable environments.

4. Types of Lighting Fixtures

- LED High Bay Lights – Best for large factories with high ceilings.

- LED Linear Lights – Ideal for production lines and workstations.

- LED Floodlights – Used for outdoor factory spaces and security lighting.

- LED Vapor Lights – Perfect for high-humidity, dust-prone environments.

- Explosion-Proof LED Lights – Essential for hazardous locations.

- LED Panel Lights – Great for offices, control rooms, and meeting spaces.

- LED Tube Lights – Cost-effective replacements for traditional fluorescent lighting.

5. Color Temperature and CRI

- 3000K (Warm White): Comfortable for office areas.

- 4000K (Neutral White): Balanced for factories and warehouses.

- 5000K-6500K (Cool White): Best for detailed tasks and high-precision work.

For color accuracy, choose:

- CRI 80+ for general factory lighting.

- CRI 90+ for precision work and color inspection.

6. Smart Lighting Controls

- Motion Sensors: Activate lights only when needed to save energy.

- Dimmable Lights: Adjust brightness for different tasks.

- Daylight Harvesting: Uses natural light to cut energy costs.

- IoT & Smart Controls: Integrate with factory automation for full lighting management.

7. Emergency Lighting

- Backup LED emergency lights are essential for power outages.

- Must meet NFPA 101 (Life Safety Code) and EN 1838 (Europe).

- Installed in exit routes, stairwells, and key work areas.

Choosing the right factory lighting means looking at standards, ceiling height, fixture type, and control options. A well-designed LED lighting system boosts energy efficiency, worker productivity, and workplace safety.

What Type of Lighting is Best for a Factory?

The best lighting depends on:

- Ceiling height – Taller ceilings need high bay LED lights.

- Task-specific needs – Focused task lighting improves accuracy.

- Energy efficiency – LEDs cut long-term costs.

- Safety compliance – Hazardous zones need explosion-proof lights.

Factories that switch to LED factory lights get better illumination, lower costs, and higher efficiency.

Installing and Retrofitting Factory Lighting

Whether setting up new factory lighting or upgrading existing fixtures, proper installation is key to efficiency, safety, and compliance. Here’s how to do it right:

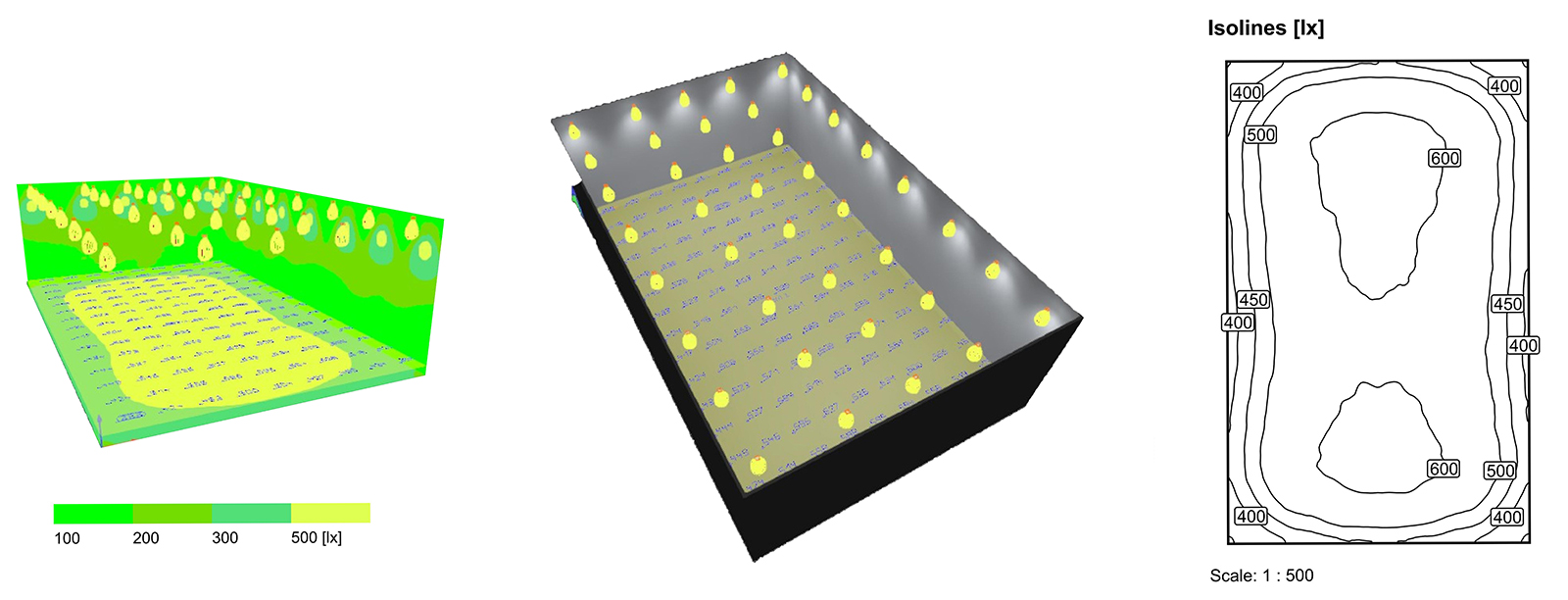

1. Planning the Lighting Layout

- Conduct a lighting audit to assess brightness levels and efficiency.

- Identify areas needing high, medium, or low lux levels.

- Use DIALux or Relux software to design an optimized lighting plan.

- Ensure glare control (UGR ≤ 22) and even light distribution.

Lighting Layout Plan

2. Choosing the Right Fixtures

- LED High Bay Lights – For high ceilings (20ft-40ft).

- LED Linear Lights – Perfect for workstations and production lines.

- Explosion-Proof LED Lights – Required for hazardous locations.

- LED Floodlights – Best for outdoor areas and security.

- LED Panel Lights – Ideal for offices and control rooms.

- LED Vapor Lights – Great for moisture-heavy areas.

3. Installing New Light Fixtures

A. Pre-Installation Checklist

✔ Turn off power before installation.

✔ Check mounting height and fixture placement.

✔ Use IP-rated fixtures for dusty or wet environments.

✔ Ensure correct voltage and driver compatibility.

B. Mounting Options

- Suspended Installation (for high bay and linear lights)

- Ceiling-Mounted (for panel lights and vapor-proof lights)

- Pole-Mounted or Bracketed (for floodlights and high mast lights)

C. Wiring and Electrical Connection

- Secure all wiring properly to avoid electrical hazards.

- Follow manufacturer guidelines for driver installation.

- Install motion sensors or dimmers if needed.

4. Retrofitting Existing Light Fixtures

A. Why Retrofit?

- Lower cost than full replacements.

- Reduces energy use by upgrading to LEDs.

- Minimal disruption to factory operations.

B. Retrofitting Steps

- Assess Existing Fixtures: Check compatibility with LED retrofit kits.

- Choose LED Retrofit Kits: Use LED tubes, retrofit high bay kits, or LED panels.

- Disconnect Old Ballasts: Remove outdated fluorescent or HID ballasts for better efficiency.

- Install LED Drivers and Modules: Replace old components with LED-compatible drivers.

- Test and Optimize: Verify brightness and functionality before full operation.

5. Safety and Compliance

- Follow OSHA (USA) or EN 12464-1 (Europe) regulations.

- Ensure emergency lighting is properly installed.

- Use surge protection to prevent power fluctuations.

6. Maintenance Tips

- Clean fixtures regularly to maintain brightness.

- Check for dimming issues or faulty drivers.

- Replace defective units under warranty (most LEDs last 5+ years).

Properly installing and retrofitting LED lighting in factories ensures better energy efficiency, worker safety, and productivity. Whether upgrading old systems or setting up new fixtures, following best practices guarantees long-term performance.

Conclusion

Choosing the right factory lighting is essential for productivity, safety, and cost savings. Whether installing new LED fixtures or retrofitting existing ones, investing in high-quality LED lighting solutions ensures optimal working conditions and lower operating costs.

Need help finding the best factory lighting solution? Contact us today for expert recommendations!