I’ve seen it happen over and over again—businesses installing the wrong lighting and then struggling with safety hazards, rising energy bills, and drops in productivity. Poor lighting isn’t just an inconvenience—it leads to accidents, downtime, and expensive maintenance. But here’s the good news: with the right industrial lighting setup, you can boost safety, cut costs, and maximize efficiency. Let’s break it all down.

When choosing industrial lighting, I focus on three things: safety, efficiency, and durability. It’s all about balancing lumens, wattage, color temperature, and fixture resilience. My go-to choice? LED lighting—it’s energy-efficient, long-lasting, and slashes maintenance costs. And when you throw in smart controls, it gets even better. With motion sensors and automated dimming, you only use light when and where you need it, cutting operational expenses even further.

If you want a bright, safe, and cost-effective workspace, the key is picking the right fixtures and controls. Let’s dive in and make sure you avoid the common mistakes that cost businesses thousands.

Table of Contents

Common Challenges for Industrial Lighting

Industrial lighting isn’t just about flipping a switch—it’s about keeping workers safe, optimizing efficiency, and controlling costs. Too many businesses stick with outdated, inefficient lighting that drains money, creates safety hazards, and requires constant maintenance. Let’s break down the biggest lighting challenges and how to fix them for good.

Harsh Conditions

Industrial environments aren’t easy on lighting. Extreme temperatures, humidity, dust, vibrations, and chemicals wreak havoc on fixtures. If your lights aren’t built for these conditions, they won’t last long.

The Fix:

Go for IP65/IP66-rated LED fixtures that withstand dust, water, and tough environments. And if you’re dealing with flammable materials, explosion-proof lighting isn’t optional—it’s a must.

Sky-High Energy Bills

Still using HID or fluorescent lights? Bad move. These old-school fixtures burn through electricity, sending your energy bills through the roof.

The Fix:

Switch to LED industrial lighting. You’ll cut energy use by up to 70% while getting brighter, more consistent lighting. And if you add motion sensors and dimming controls, you’ll stop wasting energy in empty spaces.

Safety Risks That Cost You Big Time

Dimly lit workstations? That’s a mistake waiting to happen. Poor lighting in aisles? That’s a trip-and-fall lawsuit just waiting to hit your inbox.

The Fix:

Make sure every area meets the right lux levels:

- 200–300 lux for general warehouse space

- Up to 1000 lux for precision work

And don’t forget glare-free, flicker-free LED fixtures—because eye strain and fatigue are just as dangerous as poor lighting.

Maintenance Nightmares

Ever tried replacing a high bay light 30 feet up? It’s time-consuming, expensive, and a huge hassle. If you’re constantly swapping out bulbs, you’re throwing away money on labor and replacements.

The Fix:

Invest in long-lasting LEDs that run 50,000+ hours—that’s years of zero-maintenance lighting. No more shutting down operations just to change a few bulbs.

If you’re done with high energy bills, safety risks, and maintenance headaches, it’s time to upgrade to LED lighting. You’ll get brighter, more reliable, and cost-effective lighting that actually works for your business.

What Are the Guidelines for Industrial Lighting?

Industrial lighting isn’t just about brightness—it’s about efficiency, safety, and compliance. If the lighting is too dim, accidents happen. If it’s too harsh, workers suffer from fatigue. The key is finding the right balance to boost productivity while cutting energy costs.

Illuminance Levels (Lux Requirements)

The right brightness level depends on the work being done. Some tasks require moderate lighting, while others need high-intensity illumination for precision.

| Industrial Area | Recommended Lux Level |

|---|---|

| General warehouse storage | 100–300 lux |

| Assembly & packing areas | 300–500 lux |

| Precision workstations | 500–1000 lux |

| Loading docks & security zones | 100–200 lux |

Color Temperature (Kelvin Rating)

Color temperature affects visibility and worker alertness. The right range depends on the workspace:

- 3000K (warm white): Best for break rooms and office areas

- 4000K (neutral white): Ideal for general work areas

- 5000K–6500K (cool white): Perfect for warehouses, production lines, and inspection zones

Cooler color temperatures boost focus and visibility, making them ideal for high-precision work.

Glare Reduction

Harsh lighting causes glare, leading to eye strain and lower productivity. Here’s how to fix it:

- Use diffusers or anti-glare optics on fixtures

- Position lights correctly to avoid direct exposure

- Ensure uniform light distribution—no bright spots, no shadows

Emergency Lighting

Industrial spaces must have emergency lighting to meet safety regulations. These systems should:

- Provide at least 1 lux for escape routes

- Be battery-powered or connected to a backup generator

- Include illuminated exit signs for clear evacuation guidance

Following OSHA and EN 12464-1 ensures compliance and safety in case of a power outage.

Smart Lighting Controls

Want to lower energy costs while keeping visibility high? Here’s what works:

- Motion sensors – Lights activate only when needed

- Dimmable fixtures – Adjust brightness based on daylight levels

- Automated scheduling – Lights turn off after shifts, cutting wasted energy

Proper industrial lighting means balancing brightness, color temperature, glare control, emergency preparedness, and smart controls. When done right, it improves productivity, enhances safety, and reduces operating costs.

How Do You Calculate Industrial Lighting?

Industrial lighting isn’t guesswork—it’s a science. Too little light is dangerous, too much is wasteful. Here’s how to get the right setup.

1. Measure the Area

First, calculate your square footage:

- Multiply length × width for the total area

- If the space has multiple zones, measure them separately

- Ceiling height matters—taller ceilings require higher-lumen fixtures

2. Determine Lumen Needs

Lighting levels are measured in lux (lumens per square meter). Use this formula:

Total Lumens = Area (m²) × Required Lux

Example: A 500m² warehouse needing 300 lux:

500 × 300 = 150,000 lumens

3. Choose the Right Fixtures

- High bay lights for 20ft+ ceilings

- Low bay lights for under 20ft

- Tube lights for aisles & shelving

- Explosion-proof for hazardous zones

4. Optimize Placement

- Space high bay lights 20–30 feet apart

- Use narrow beam angles (60°-90°) for tall ceilings

- Use wide beam angles (120°-150°) for low ceilings

- Position lights strategically for even distribution

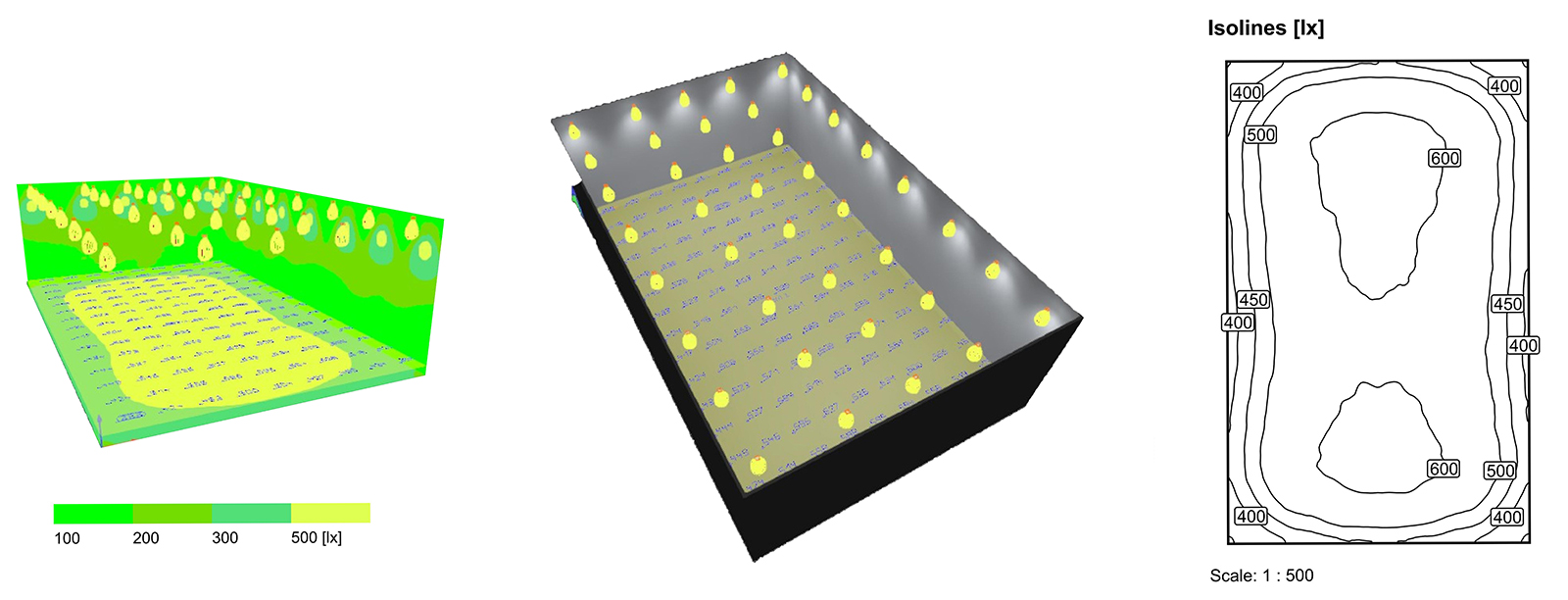

5. Run a Lighting Simulation

Use Dialux or Relux to:

✔ Verify brightness uniformity

✔ Identify dark spots needing extra fixtures

✔ Optimize light placement for efficiency

Bottom line? A well-planned lighting system saves energy, boosts productivity, and enhances workplace safety. If you’re serious about cutting costs and improving efficiency, upgrading to LED industrial lighting is the smartest move you can make.

What Are the Different Types of Industrial Lighting?

Industrial lighting isn’t just about making things brighter—it’s about efficiency, durability, and safety. The right lighting choice depends on factors like ceiling height, environmental conditions, and energy efficiency needs. Let’s break down the different types of industrial lighting and where they work best.

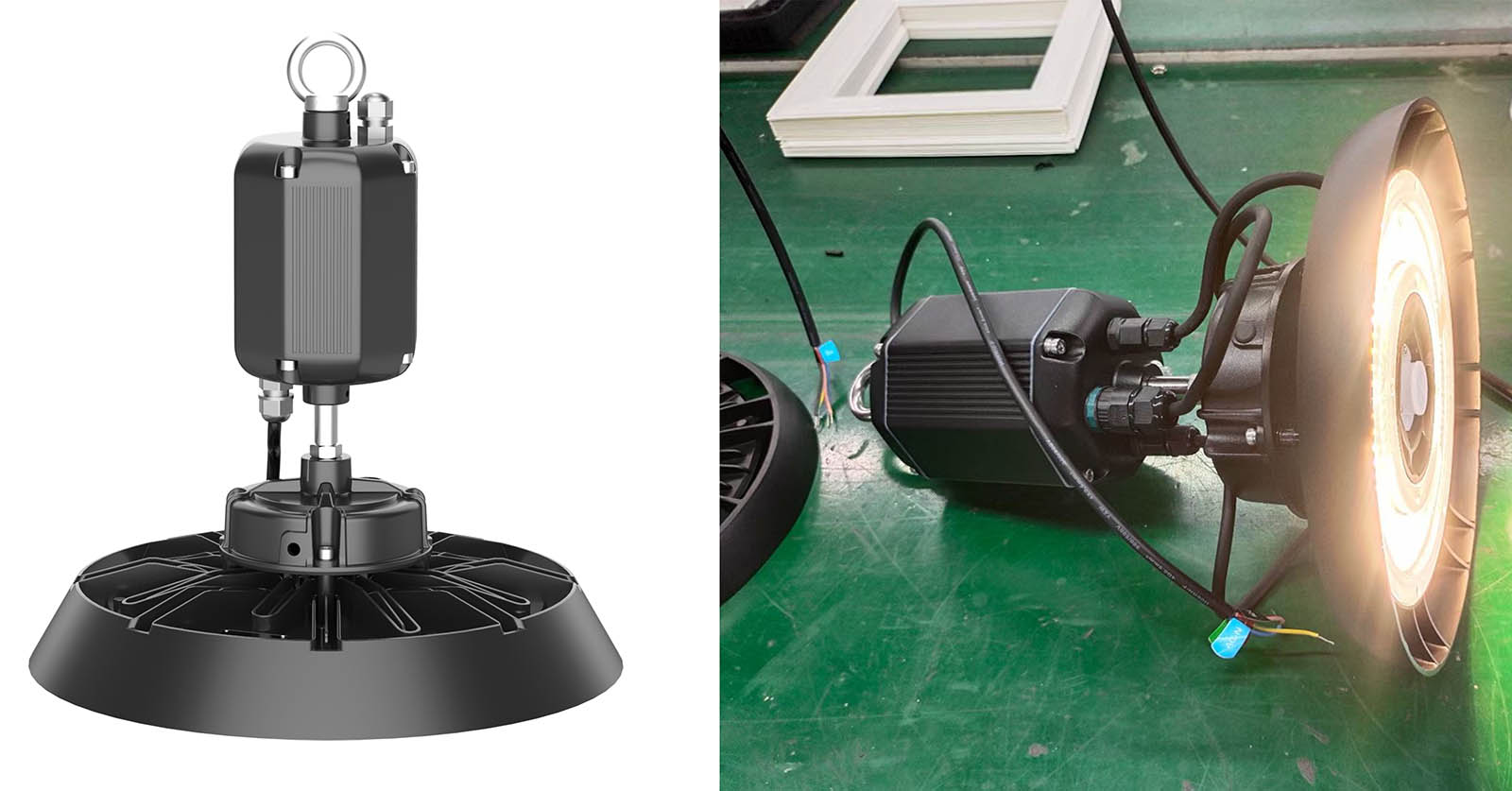

LED High Bay Lights

High bay lights are built for industrial spaces with ceilings over 20 feet. They provide uniform, high-powered illumination that keeps large spaces well-lit and shadow-free.

- High lumen output ensures clear visibility in massive areas.

- Available in various beam angles to match different layouts.

- Energy-efficient, cutting electricity costs by up to 70%.

- Perfect for: Warehouses, factories, airplane hangars, and distribution centers.

LED Flood Lights

Flood lights provide wide-area illumination for both indoor and outdoor industrial spaces. These are ideal for security, perimeter lighting, and open work areas.

- Bright, high-intensity lighting covers large spaces efficiently.

- IP65/IP66-rated for weather resistance—built to handle rain, dust, and extreme conditions.

- Mount on walls, poles, or ceilings for flexible installation.

- Perfect for: Loading docks, parking lots, industrial yards, and sports complexes.

LED Linear Lights

LED linear lights are long, strip-like fixtures designed for assembly lines, workstations, and warehouse aisles. They provide consistent, even illumination to eliminate shadows and dark spots.

- Flicker-free lighting reduces worker fatigue.

- Slim, space-saving design for compact setups.

- Available in suspended or surface-mounted options.

- Perfect for: Conveyor belts, manufacturing lines, and warehouse aisles.

LED Street Lights

Factories and industrial facilities often need outdoor lighting for roads, parking lots, and walkways. LED street lights offer long-lasting, low-maintenance illumination that keeps outdoor spaces secure.

- Photocell and motion sensor options for maximum energy savings.

- High lumen-per-watt efficiency reduces power costs.

- Built to handle extreme weather conditions with IP65+ ratings.

- Perfect for: Industrial roads, factory perimeters, and large parking areas.

Explosion-Proof Lights

Explosion-proof lighting is designed for hazardous environments where flammable gases, vapors, or dust are present. These fixtures prevent sparks and overheating, ensuring workplace safety and compliance.

- Built with impact-resistant, heavy-duty materials.

- Meets ATEX, IECEx, and UL safety standards.

- Essential for high-risk locations like refineries and chemical plants.

- Perfect for: Oil refineries, chemical plants, offshore platforms, and industrial mines.

LED Vapor Tight Lights

Vapor-tight lights are built for harsh, high-moisture environments. These fixtures are sealed to prevent contamination and corrosion, making them ideal for wet and dusty conditions.

- IP66-rated for full water and dust protection.

- Corrosion-resistant materials ensure durability.

- Used in cold storage, food processing, and outdoor workspaces.

- Perfect for: Refrigerated warehouses, food production plants, and car washes.

The right industrial lighting depends on your environment, efficiency goals, and operational needs. Whether you need high bay lights for warehouses, explosion-proof fixtures for hazardous areas, or LED flood lights for outdoor security, investing in the right lighting boosts safety, productivity, and cost savings.

How to Choose Lighting for Harsh Industrial Environments

Not all industrial environments are lighting-friendly. Extreme temperatures, dust, moisture, and power surges can destroy standard fixtures, leading to costly replacements and downtime. If you’re dealing with factories, warehouses, oil refineries, or food processing plants, here’s what to look for in a durable, long-lasting lighting solution.

IP65/IP66 Rated Fixtures

If your facility has moisture, dust, or airborne chemicals, your lighting must have a high Ingress Protection (IP) rating.

- IP65-rated fixtures resist dust and low-pressure water jets, making them great for manufacturing plants, warehouses, and workshops.

- IP66-rated fixtures handle heavy rain, high-pressure washdowns, and outdoor exposure, perfect for food processing, oil refineries, and wet environments.

- Corrosion-resistant housing prevents rust in high-humidity or chemical-exposed areas.

High-Temperature Resistance

Industrial lighting must survive extreme heat, which can degrade LEDs, cause flickering, or lead to failures.

- Heat-resistant LED fixtures withstand temperatures above 50°C (122°F) without performance loss.

- Aluminum heat sinks and advanced thermal management prevent overheating.

- Perfect for: Steel mills, foundries, glass manufacturing, and high-heat processing plants.

Durable Construction

Industrial lighting needs to handle impact, vibrations, and constant use without failing.

- Die-cast aluminum housing ensures shock resistance and long-term durability.

- Tempered glass or polycarbonate lenses prevent shattering.

- Vibration-resistant mounts keep lights stable near heavy machinery.

- Perfect for: Shipyards, mines, transportation hubs, and vibrating industrial zones.

Surge Protection

Industrial sites experience power surges and voltage spikes from heavy machinery and unstable grids. If unprotected, LEDs can burn out quickly.

- Built-in surge protectors (10kV or higher) prevent electrical damage.

- Industrial-grade voltage stabilizers help avoid unexpected failures.

- A must-have for: Power plants, oil rigs, and manufacturing sites with fluctuating power loads.

Smart Controls

Want to cut costs and increase efficiency? Automated lighting controls help manage energy usage in real-time.

- Motion sensors activate lights only when needed, saving energy.

- Dimmable LEDs adjust brightness based on work hours or daylight levels.

- Remote monitoring systems let you control lighting from anywhere.

- Perfect for: Warehouses, logistics hubs, and 24/7 operations.

Lighting in harsh industrial environments needs waterproof and dustproof protection (IP65/IP66), heat resistance, impact durability, surge protection, and smart controls. These features extend fixture life, enhance safety, and lower maintenance costs.

What Type of Lighting Is Best for a Factory?

Factories need bright, uniform, and glare-free lighting to keep workspaces safe and efficient. Here’s what works best:

- LED High Bay Lights – Best for tall ceilings and large areas.

- LED Linear Lights – Ideal for production lines and conveyor belts.

- Tunable White Lighting – Lets you adjust color temperature for different tasks.

- Motion Sensor Lighting – Cuts energy costs by activating only when needed.

Conclusion

Choosing the right industrial lighting isn’t just about visibility—it’s about working smarter, cutting costs, and improving safety. LED fixtures outperform traditional lighting in energy efficiency, durability, and maintenance costs. Whether you need warehouse lighting, explosion-proof fixtures, or floodlights for outdoor security, a well-planned lighting system enhances productivity, reduces expenses, and ensures compliance.

Need expert advice on industrial lighting solutions? Reach out today, and let’s find the perfect setup for your business!