Choosing the right LED chip can be confusing. With so many options like 2835, 3030, and 5050, picking the wrong one can lead to poor lighting performance, high energy consumption, and unnecessary costs. Understanding the differences helps you select the best LED chip for your needs.

The numbers in LED chip names, such as 2835, 3030, and 5050, represent their physical size in millimeters. Each type has different brightness, wattage, and applications. 2835 LEDs are compact and efficient, 3030 LEDs are high-powered for commercial and industrial lighting, and 5050 LEDs offer high brightness with multi-color capability. Choosing the right LED chip depends on factors like heat dissipation, efficiency, and intended use. This guide breaks down the key differences and helps you decide which is best for your lighting project.

Still unsure which LED chip is right for your project? Let’s explore the details.

Table of Contents

What Does the Number of an LED Chip Mean?

The number in an LED chip’s name refers to its dimensions in tenths of a millimeter. For example:

– 2835 LED measures 2.8mm x 3.5mm.

– 3030 LED measures 3.0mm x 3.0mm.

– 5050 LED measures 5.0mm x 5.0mm.

These sizes influence power output, brightness, and application. Smaller chips like 2835 are energy-efficient, while larger chips like 5050 can support multiple diodes for RGB lighting.

Key Differences Between 2835, 3528, 3030, 4014, 5050, and 5630 LED Chips

Difference Between LED 2835 vs LED 3030 vs 5050 and others

Understanding the differences between various LED chips is essential for selecting the right type for specific applications. Factors like size, brightness, wattage, cost, and applications determine how these LED chips perform in different lighting environments.

Size

The size of an LED chip impacts its brightness, efficiency, and heat dissipation.

- 2835: Measures 2.8mm x 3.5mm, making it compact yet powerful. It is widely used in LED panel lights, downlights, strip lights, and floodlights due to its balance between efficiency and output.

- 3528: Measures 3.5mm x 2.8mm, similar in size to the 2835 but has a lower power output, making it ideal for applications that not require high brightness.

- 3030: Measures 3.0mm x 3.0mm and is known for high-power output. It is used in industrial and commercial lighting applications, including streetlights, floodlights and stadium lights, etc.

- 4014: Measures 4.0mm x 1.4mm, featuring a slim design. This shape makes it well-suited for LED panel lighting, where a compact form factor is required.

- 5050: Measures 5.0mm x 5.0mm, allowing for multiple diodes within a single chip. This feature makes it a popular choice for RGB strip lights and high-brightness applications.

- 5630: Measures 5.6mm x 3.0mm and is known for higher brightness and efficiency. It is often used in commercial and industrial settings, such as high-output LED fixtures.

Brightness

The brightness of an LED chip is determined by its lumen output per watt and power efficiency.

- 2835 LEDs offer high brightness with low power consumption, making them an efficient choice for general lighting.

- 3030 LEDs are designed for high-lumen output and are widely used in high-power floodlights, streetlights, and industrial applications.

- 5050 LEDs provide high brightness and are commonly used in RGB applications, as they can house multiple diodes in one chip.

- 5630 LEDs are among the brightest, making them suitable for commercial and industrial applications requiring high-intensity lighting.

Wattage

LED chips consume different amounts of power based on their design and intended application.

- 5050 LED wattage: Typically 3.0W–5.0W per LED due to its multi-diode structure. It is commonly used in RGB lighting and high power lighting.

- 2835 LED wattage: Typically 0.2W–0.5W per LED, but high-power versions with 1.0W per LED are also available for brighter applications.

- 3030 LED wattage: Typically 1.0W per LED, designed for high-power fixtures like stadium lights and industrial lighting.

Cost

The cost of an LED chip is influenced by its efficiency, power output, and functionality.

- 2835 LEDs are cost-effective and widely used in commercial and residential lighting due to their balance of efficiency and brightness.

- 3030 LEDs are slightly more expensive than 2835 but provide higher brightness and power output, making them ideal for industrial and outdoor lighting.

- 5050 LEDs tend to be more expensive due to their multi-diode capability and RGB color-changing functions.

Applications

Each LED chip has specific use cases depending on its design and efficiency.

- 2835 LED: Common in indoor LED strip lights, panel lights, down lights, and general commercial and industrial lighting due to its efficiency and affordability.

- 3030 LED: Found in high bay lights, floodlights, stadium lights, streetlights, and other high-power LED fixtures.- 4014 LED: Used primarily in LED panel lights and thin-profile fixtures where a slim design is necessary.

- 5050 LED: Popular in RGB strip lights, decorative lighting, and high-brightness applications due to its ability to house multiple diodes for color mixing.

- 5630 LED: Ideal for industrial and commercial environments, as well as high-brightness LED fixtures in warehouses and factories.

| Feature | 2835 | 3528 | 3030 | 4014 | 5050 | 5630 |

|---|---|---|---|---|---|---|

| Size (mm) | 2.8 x 3.5 | 3.5 x 2.8 | 3.0 x 3.0 | 4.0 x 1.4 | 5.0 x 5.0 | 5.6 x 3.0 |

| Brightness | High brightness with low power consumption. | Low brightness, suitable for basic applications. | High lumen output for industrial and street lighting. | Moderate brightness, used in LED panel lights. | High brightness, supports multiple diodes (RGB or white). | Among the brightest, used in commercial and industrial settings. |

| Wattage | 0.2W–0.5W per LED (some versions 1.0W). | Low wattage, not designed for high power. | 1.0W per LED, used in high-power applications. | Low to moderate wattage, designed for panel lighting. | 3.0W–5.0W per LED, high power for RGB or industrial use. | Higher wattage than 2835 but efficient for industrial applications. |

| Heat Dissipation | Excellent thermal efficiency, generates less heat. | Lower heat output due to low power. | Requires proper heat sinks for better thermal management. | Good heat dissipation due to slim design. | Generates more heat, needs proper cooling. | Higher heat output, requires good ventilation. |

| Cost | Cost-effective, widely used for general lighting. | Budget-friendly but limited in applications. | Slightly more expensive but offers better brightness. | Affordable, primarily used in LED panels. | More expensive due to multi-diode capability and RGB functionality. | Higher cost due to industrial-grade performance. |

| Applications | LED strip lights, panel lights, downlights, floodlights. | Basic indoor lighting, signage, low-power applications. | High bay lights, streetlights, stadium lights, floodlights. | LED panel lights, thin-profile fixtures, indoor displays. | RGB lighting, decorative lighting, high-brightness applications. | Warehouses, factories, industrial environments, commercial lighting. |

Different LED chips offer unique advantages based on size, brightness, wattage, and cost. The 2835 and 4014 LEDs are great for cost-effective general lighting, while 3030 and 5050 LEDs are best for high-power industrial applications. The 5050 LED is the preferred choice for RGB and decorative lighting, and 4014 LEDs are ideal for slim-profile panel lighting. Understanding these differences helps in selecting the right LED chip for specific lighting needs.

What is the Lifespan of SMD LED?

The lifespan of an SMD (Surface-Mounted Device) LED depends on various factors, including the quality of the LED chip, operating conditions, thermal management, and power supply efficiency. On average, SMD LEDs last between 30,000 to 100,000 hours, significantly longer than traditional incandescent or fluorescent lighting.

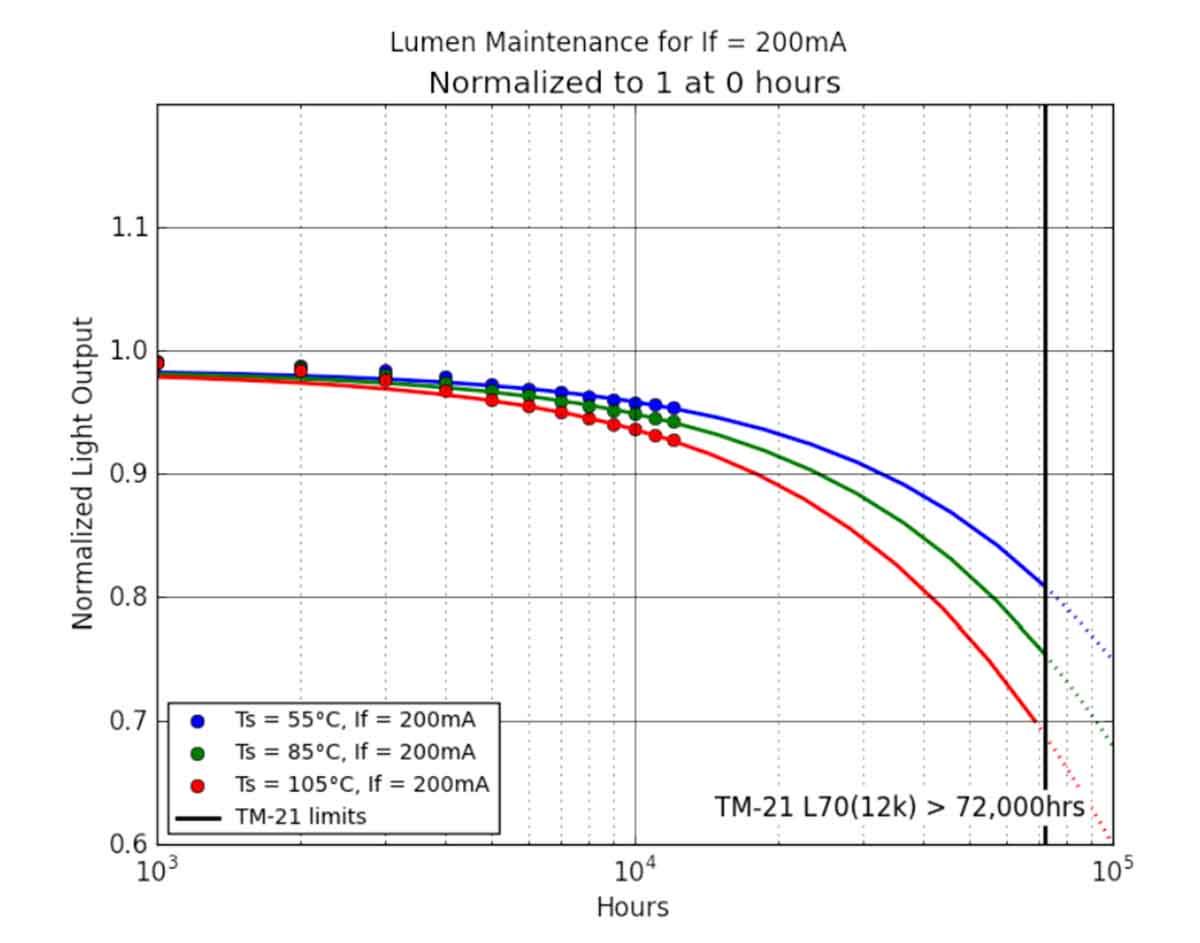

Lifetime of Lumileds LUXEON 5050

Factors Affecting SMD LED Lifespan

- LED Chip Quality

High-quality LED chips from reputable manufacturers tend to have longer lifespans. Premium brands like Cree, Osram, and Lumileds produce LEDs that can last up to 100,000 hours under optimal conditions. -

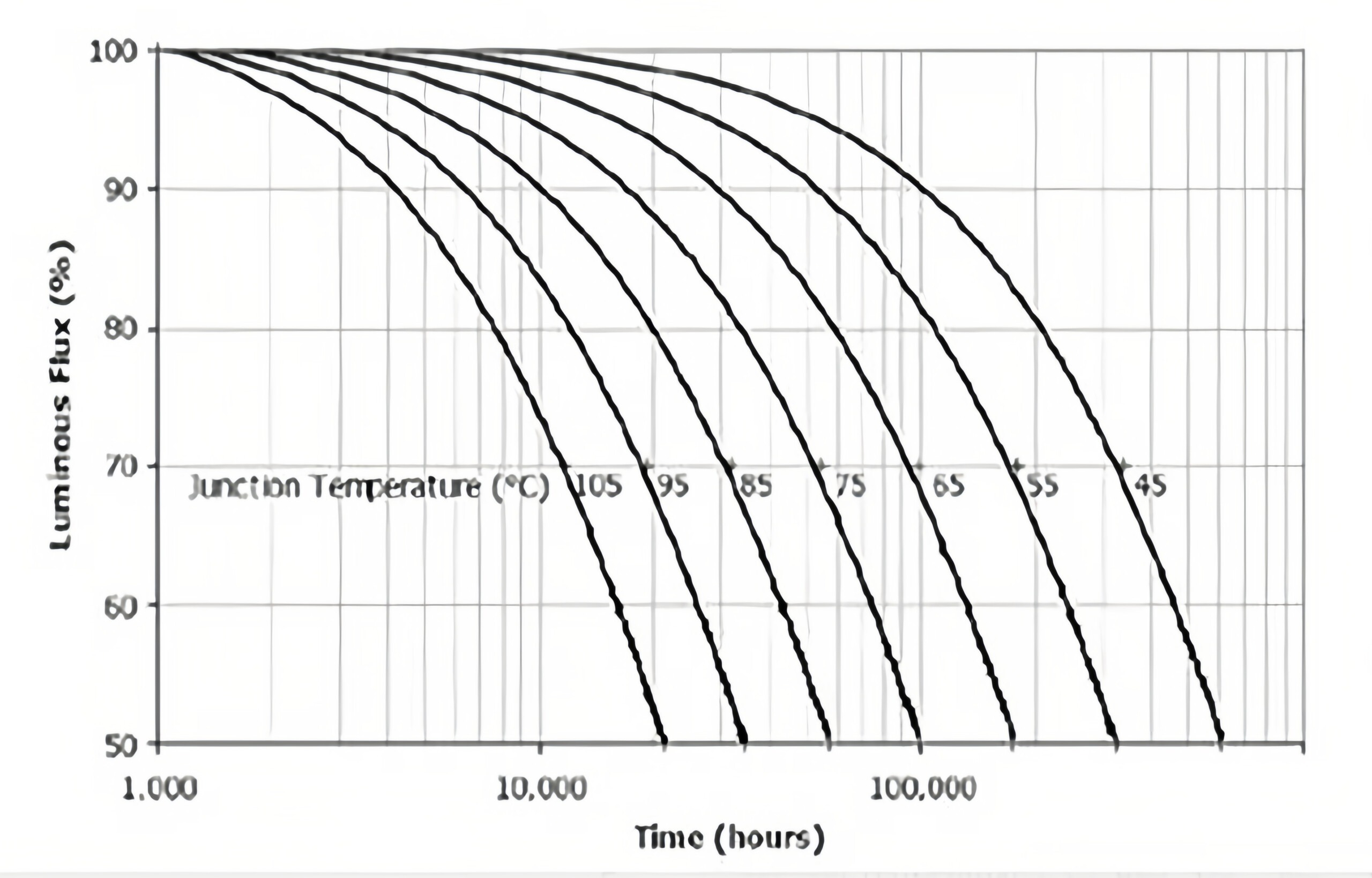

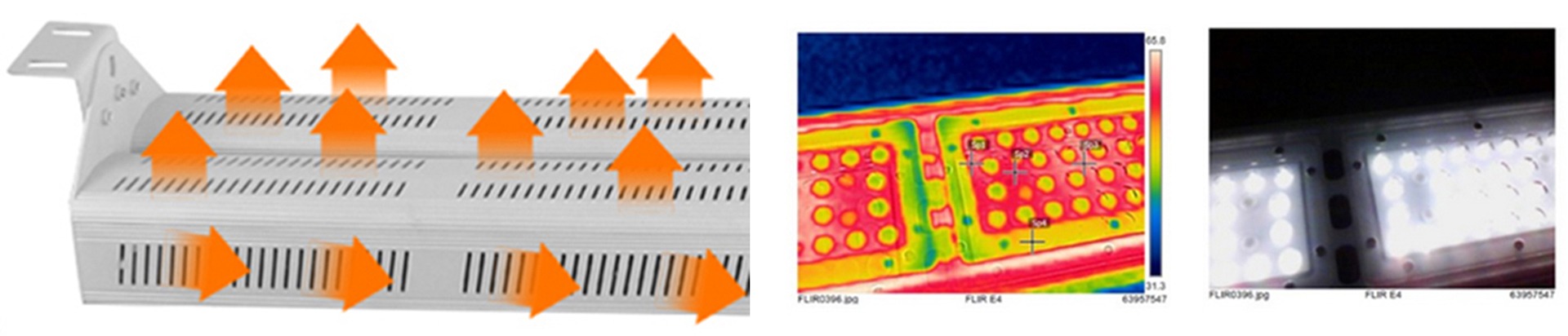

Operating Temperature

Heat is a major factor affecting LED lifespan. Excessive heat buildup can shorten an LED’s life, so proper heat dissipation through aluminum heat sinks or thermal pads is essential. LEDs that operate at lower temperatures generally last longer.

Temperature and Life Decay

- Drive Current and Power Supply

Running an LED at its maximum rated current reduces its lifespan. Using an efficient LED driver with stable voltage and current regulation helps extend the longevity of SMD LEDs. Overvoltage and power fluctuations can cause premature failure. -

Environmental Conditions

SMD LEDs used in harsh environments with high humidity, dust, or extreme temperatures may degrade faster. IP65 or IP67-rated LEDs are recommended for outdoor or industrial applications to protect against moisture and dust. -

Usage and Duty Cycle

LEDs used continuously at full brightness wear out faster than those that are dimmed or used intermittently. Implementing smart lighting controls or dimming can reduce strain and extend the lifespan of the LED.

How to Maximize SMD LED Lifespan

- Use high-quality LED chips from reputable manufacturers.

- Ensure proper thermal management with adequate heat sinks or cooling systems.

- Choose a reliable LED driver with stable power output.

- Install LEDs in well-ventilated environments to reduce overheating.

- Consider dimming controls to reduce full-power operation and extend longevity.

The lifespan of an SMD LED can vary based on quality and operating conditions. Under ideal conditions, high-quality SMD LEDs can last up to 100,000 hours, while lower-end models may only last 30,000 to 50,000 hours. Proper installation, power regulation, and heat management are crucial for maximizing the durability and performance of SMD LEDs.

Pros and Cons Between Different Types of LED Chips: 2835, 3030, 4014, and 5050

Different LED chips offer various benefits and drawbacks based on their design, efficiency, and intended applications. Here’s a comparison of the 2835, 3030, 4014, and 5050 LED chips, highlighting their pros and cons.

Pros and Cons of Different LED Chips

| LED Chip | Pros | Cons |

|---|---|---|

| 2835 | High efficiency with low power consumption. <br> Generates less heat, improving lifespan. <br> Compact design, suitable for LED strips, panel lights, and downlights. <br> Cost-effective for general lighting applications. | Lower brightness compared to larger chips. <br> Not ideal for high-power applications like floodlights. |

| 3030 | High brightness and lumen output. <br> Excellent for high-power lighting such as streetlights and stadium lights. <br> Better thermal management, ensuring longer lifespan. | Higher cost than smaller chips like 2835. <br> Requires better heat dissipation1 due to higher power consumption. |

| 4014 | Slim and compact design, ideal for LED panel lighting. <br> Provides even and uniform illumination. <br> Efficient power consumption. | Lower brightness compared to 3030 or 5050. <br> Not suitable for high-output applications. |

| 5050 | High power output and brightness. <br> Supports multiple diodes, making it ideal for RGB lighting. <br> Used in decorative, accent, and high-lumen applications. | Consumes more power, leading to higher heat output. <br> Requires proper cooling to maintain lifespan. <br> More expensive compared to 2835 and 4014. |

The choice of LED chip depends on the lighting requirements. The 2835 LED is best for cost-effective and efficient general lighting, while the 3030 LED is ideal for high-power applications. The 4014 LED is preferred for slim-profile panel lighting, and the 5050 LED is the best option for RGB and decorative lighting. Each chip type has its strengths, making it essential to select the right one based on the specific application.

5 Factors to Consider Before Choosing Different LED Chips

Selecting the right LED chip for your lighting project requires considering various factors, including brightness, heat dissipation, efficiency, wattage, and cost. Each type of LED chip has distinct advantages depending on the application. Below are five key factors to consider before making a choice.

Brightness

The brightness of an LED chip is measured in lumens per watt and varies depending on the type of chip used.

- If the goal is general lighting for homes, offices, or commercial spaces, 2835 LEDs are a cost-effective and energy-efficient option.

- For high-brightness applications such as stadium lights, streetlights, or industrial lighting, 3030 LEDs provide higher lumen output.

- If color-changing or RGB effects are required, 5050 LEDs are the best choice, as they support multiple diodes within a single chip, allowing for vibrant and dynamic lighting effects.

Heat Dissipation

Heat management is crucial for the longevity and performance of LED chips2. Poor heat dissipation can reduce efficiency and shorten lifespan.

- 2835 LEDs have excellent thermal efficiency, producing minimal heat, making them suitable for panel lights, down lights, strip lights, and indoor fixtures.

- 3030 LEDs, being high-power chips, require proper heat sinks and advanced cooling systems, making them ideal for industrial and outdoor lighting applications.

- 5050 LEDs generate more heat due to their multiple diodes and higher power consumption. Proper ventilation and heat dissipation materials are necessary to ensure their longevity, especially in RGB lighting setups.

Efficiency

LED efficiency determines how much electrical energy is converted into usable light.

- 2835 and 3030 LEDs are among the most efficient options, providing high lumens per watt while consuming less energy. This makes them ideal for general and industrial lighting where energy savings are a priority.

- 5050 LEDs, while offering high brightness and RGB capabilities, are less efficient due to their higher power consumption and multi-diode design. They are best used for decorative and entertainment lighting, where energy efficiency3 is not the main concern.

Wattage

The wattage of an LED chip affects power consumption and overall system efficiency.

- 5050 LED chips typically consume higher wattage due to their multi-diode structure, making them more power-intensive but capable of producing vibrant lighting effects.

- 2835 LEDs, known for their low power consumption, are perfect for cost-effective, energy-saving applications in residential and commercial lighting.

- 3030 LEDs fall between the two, offering a balance of moderate power usage and high brightness, making them suitable for industrial and high-output lighting applications.

Cost

Cost plays a significant role in choosing an LED chip, as it impacts the overall budget for lighting projects.

- 2835 LEDs are budget-friendly and provide an affordable solution for everyday lighting applications without compromising efficiency.

- 3030 LEDs are more expensive than 2835 but offer superior brightness and durability, making them a worthwhile investment for high-performance lighting solutions.

- 5050 LEDs are the most expensive due to their RGB functionality and multi-diode capability. These chips are mainly used in entertainment lighting, accent lighting, and decorative installations, where color control and dynamic effects are needed.

Choosing the right LED chip depends on the brightness, heat dissipation, efficiency, wattage, and cost required for the application. 2835 LEDs are perfect for low-cost, energy-efficient general lighting, while 3030 LEDs excel in high-brightness and industrial applications. 5050 LEDs are best for RGB and decorative lighting, offering stunning visual effects but with higher power consumption and cost. Carefully considering these factors ensures that the LED chip selected meets the functional and economic requirements of the project.

Conclusion

Choosing the right LED chip depends on your lighting needs. 2835 LEDs are ideal for general lighting, 3030 LEDs offer high brightness for commercial and industrial applications, and 5050 LEDs are best for RGB and decorative lighting. Understanding wattage, brightness, and efficiency helps ensure you get the best performance and value for your project.

Need help selecting the right LED chips for your lighting solution? Contact us today for expert advice and high-quality LED products!

- Learn about the importance of heat dissipation in LED chips to ensure longevity and efficiency in your lighting solutions. ↩

- Explore this resource to understand the various types of LED chips and their specific applications, helping you make informed choices for your lighting projects. ↩

- Discover insights on energy efficiency in LED chips, which is crucial for reducing costs and environmental impact in lighting applications. ↩