Struggling with poor lighting in large spaces can lead to decreased productivity and safety hazards. Without proper illumination, tasks become challenging, and accidents may increase. Upgrading to LED high bay lights offers a solution, providing bright, efficient lighting tailored for expansive areas.

Choosing the right LED high bay light involves evaluating factors like lumen output, wattage, color temperature, ceiling height, and energy efficiency to ensure optimal performance and cost savings. Various types, such as UFO, linear, vapor tight, motion sensor, and explosion-proof models, are tailored for specific spaces—from warehouses to high-heat industrial zones—allowing you to match the fixture to your environment for reliable and efficient lighting.

Let’s delve deeper into understanding and selecting the right LED high bay lights for your needs.

Table of Contents

What are LED High Bay Lights?

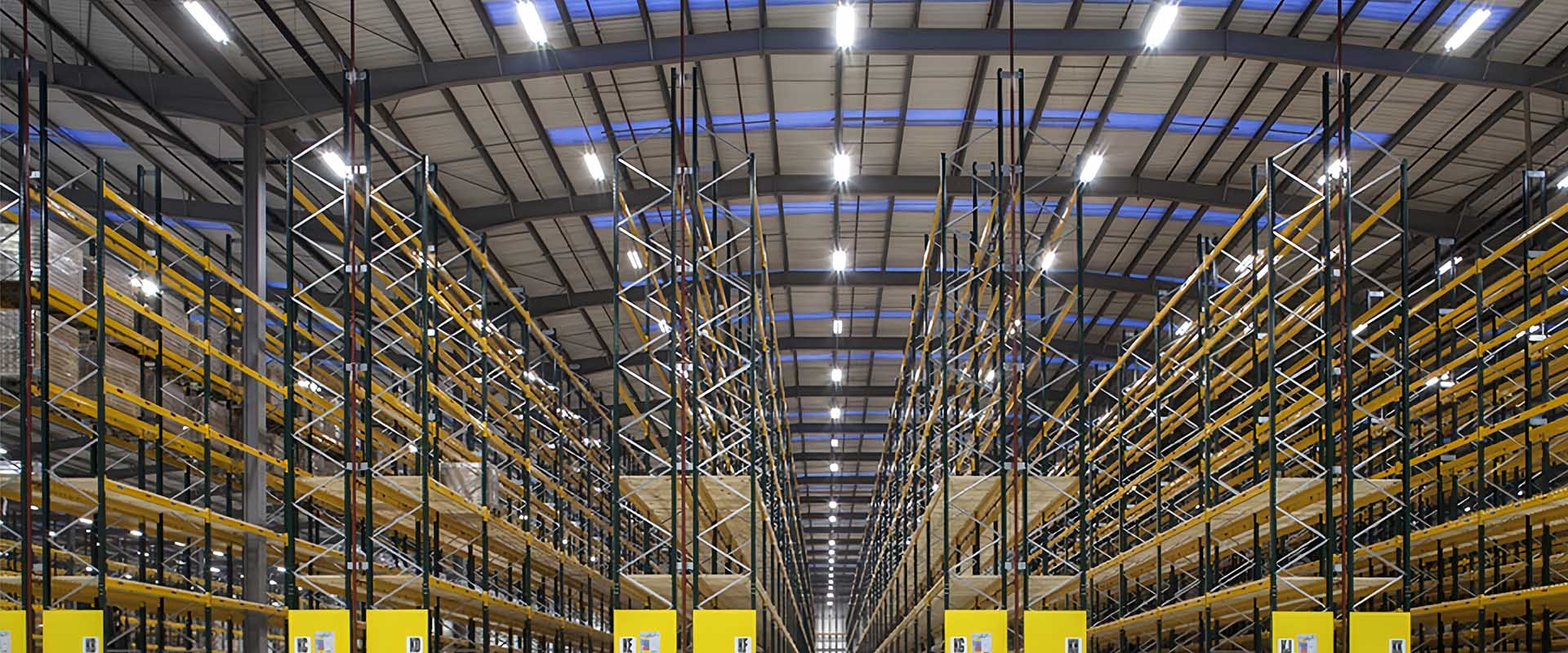

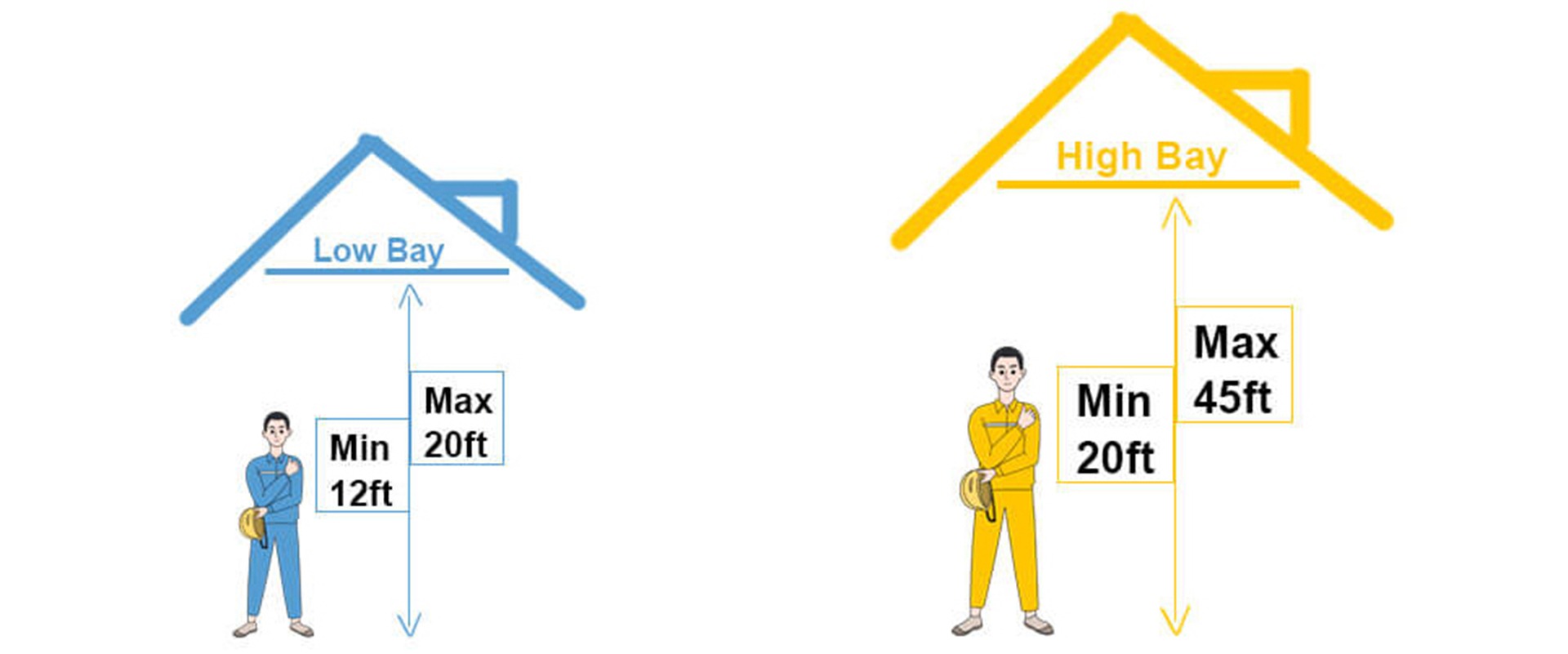

LED high bay lights are a type of lighting fixture designed to provide bright, efficient illumination in large indoor spaces with high ceilings—typically between 6 to 12 meters. These lights are most commonly used in settings such as warehouses, factories, gymnasiums, hangars, supermarkets, and other industrial or commercial buildings where broad and powerful lighting coverage is needed.

The term “high bay” refers to the height at which these lights are installed. Because the ceilings are so tall, the lights need to produce a high lumen output to ensure the light reaches the floor evenly and clearly. LED high bay lights are specifically built for this purpose. They offer excellent brightness, consistent light distribution, and reduced glare, making the environment safer and more comfortable for people working or moving around in the space.

Compared to traditional high bay lighting like metal halide or fluorescent fixtures, LED high bays consume less power, produce less heat, and have a much longer lifespan. They also turn on instantly without any warm-up time and often come with dimming and smart control options.

Whether it’s for a large warehouse or a tall indoor sports arena, LED high bay lights deliver strong performance while saving energy and reducing maintenance needs.

Why Choose High Bay LED Lights?

High bay LED lights offer a smart and efficient solution for lighting large, high-ceiling spaces. Here’s why they are the preferred choice over traditional lighting systems:

- Energy Savings: LED high bay lights use far less electricity compared to metal halide, fluorescent, or halogen fixtures. This lower energy consumption results in significantly reduced electricity bills, especially in facilities where lights are on for long hours each day.

-

Long Lifespan: One of the standout benefits of LED technology is its durability. Most high bay LED lights last between 50,000 to 100,000 hours. This extended life reduces how often you need to replace bulbs, cutting down maintenance work and costs.

-

Better Light Quality: LED high bay lights deliver bright, uniform illumination across large areas. This consistent lighting improves visibility, making it easier for employees to work safely and efficiently. There’s less flickering, fewer shadows, and better color rendering compared to older lighting technologies.

-

Instant On and Off: Unlike traditional lighting systems that take time to warm up, LEDs turn on instantly at full brightness. This is especially useful in warehouses, gyms, or manufacturing areas where immediate light is needed.

-

Low Heat Output: LEDs generate less heat than traditional lighting, which helps maintain a cooler indoor environment. This can be important in temperature-sensitive spaces or where heat buildup is a concern.

-

Environmentally Friendly: LED high bays contain no harmful substances like mercury and are fully recyclable. They also support green building standards and help reduce carbon emissions due to their lower energy use.

-

Optional Smart Controls: Many LED high bay lights can be paired with motion sensors, dimming features, or time-based controls. This adds flexibility and further improves energy efficiency by reducing light output when full brightness isn’t needed.

Choosing high bay LED lights means better performance, lower operational costs, and a safer, more productive workspace.

Factors to Consider When Selecting LED High Bay Lights

Choosing the right LED high bay light ensures your space is well-lit, energy-efficient, and safe. Here are the key factors to keep in mind before making a decision:

- Lumen Output: Lumen output measures how much visible light a fixture produces. Make sure the light provides enough brightness for the size and use of your space. Warehouses, gymnasiums, and production facilities typically require higher lumen levels to maintain clear visibility.

-

Wattage: While wattage indicates how much power the light uses, it’s important to strike a balance between energy use and brightness. Modern LED high bays offer high lumen output with lower wattage, helping reduce electricity costs without sacrificing light quality.

-

Color Temperature: Color temperature affects how the space looks and feels. For most industrial or commercial settings, a color temperature between 4000K (neutral white) and 5000K (cool white) is ideal. This range provides clear visibility and reduces eye strain, which is important in work environments.

-

Mounting Height: Ceiling height directly impacts which light you should choose. For spaces with ceilings between 6 to 12 meters, select fixtures with the appropriate beam angle and intensity to ensure even coverage. Higher ceilings typically need more powerful lights with narrower beam angles to focus the light downward.

-

Energy Efficiency: Look for LED high bay lights with a high lumens-per-watt (lm/W) rating. This indicates how much light you get per unit of power used. The higher the lm/W, the more efficient the light, which means better performance and lower energy bills.

By considering these factors, you can choose LED high bay lights that provide excellent lighting performance, reduce operating costs, and support long-term durability.

Types of High Bay Lights and Their Ideal Applications

Selecting the right type of high bay light depends on your facility’s layout, environment, and lighting needs. Each type offers unique benefits for specific applications. Here’s a breakdown to help you decide what’s best for your space:

UFO High Bay Lights

UFO high bay lights get their name from their compact, round shape. They offer a wide beam angle and are excellent for open, high-ceiling environments. Their design includes efficient heat dissipation, making them highly durable. Ideal applications include warehouses, manufacturing plants, and gymnasiums where broad, even lighting is essential.

Linear High Bay Lights

These lights resemble traditional fluorescent tubes but deliver the performance and efficiency of LED technology. They work best in long, narrow areas such as aisles, corridors, or storage racks. Retail stores, distribution centers, and libraries benefit most from linear high bay lighting due to its ability to provide uniform coverage across elongated spaces.

Vapor Tight High Bay LED Lights

Vapor tight high bays are built to resist moisture, dust, and harsh conditions. They are sealed and rugged, making them ideal for areas where water, steam, or dirt is common. These lights are commonly used in car washes, food processing plants, and other damp or dusty industrial environments.

LED Hazardous Location and Explosion Proof High Bay Lights

These fixtures are specifically engineered for environments where flammable gases, dust, or chemicals are present. They are certified for use in hazardous areas and help prevent ignition of dangerous substances. Suitable for oil refineries, chemical plants, and grain storage facilities.

Motion Sensor High Bay Lights

These lights come with built-in motion sensors that detect occupancy and adjust lighting accordingly. They save energy by turning off or dimming when no activity is detected. Perfect for storage areas, cold rooms, or warehouses where lighting needs fluctuate based on usage.

Dimmable High Bay Lights

Dimmable high bays allow you to adjust brightness levels based on specific tasks, time of day, or energy-saving needs. They offer more control and can help reduce power consumption. Great for multi-use spaces like workshops, arenas, or exhibition halls.

High Voltage 480V Warehouse Lights

For facilities using high-voltage systems, these lights are designed to operate efficiently at 347V or 480V. They eliminate the need for step-down transformers and simplify installation in industrial plants or large-scale warehouses with high-voltage infrastructure.

LED High Bay Lights With Remote LED Drivers for High Heat Locations

In spaces where temperatures stay high—like foundries or metal workshops—standard LED drivers may fail early. These high bay lights feature remote drivers that can be installed in cooler areas, protecting the sensitive electronics and extending the fixture’s lifespan.

By understanding these different types of LED high bay lights, you can match the right fixture to your specific environment, improving both efficiency and performance.

Cost Analysis of LED High Bay Retrofitting

Retrofitting existing high bay lighting systems with LEDs may require a higher upfront investment, but the long-term savings make it a smart financial decision for most facilities. Here’s a breakdown of the key cost factors and savings benefits:

Initial Investment

Switching from traditional lighting like metal halide or fluorescent fixtures to LED high bay lights often involves purchasing new fixtures or retrofit kits. Costs will vary based on the size of the facility, the number of lights needed, and whether installation is handled in-house or by a contractor.

While LED fixtures cost more upfront than conventional lights, they come with built-in features like better optics, longer lifespans, and lower power usage, which help offset the initial spend over time.

Energy Savings

LED high bay lights use up to 70% less electricity compared to older lighting systems. This translates into significant monthly savings on energy bills, especially in facilities where lights operate for long hours or 24/7.

For example, replacing a 400W metal halide fixture with a 150W LED can save hundreds of dollars in electricity per light annually. Multiply that by dozens or even hundreds of fixtures in a warehouse, and the savings quickly add up.

Maintenance Reduction

Traditional lighting systems require frequent bulb and ballast replacements. These maintenance tasks not only cost money in parts and labor but also cause disruptions in daily operations. LED high bay lights last 50,000 hours or more, reducing the need for service calls and ladder time.

Fewer replacements mean lower maintenance costs, less downtime, and improved safety for workers.

Return on Investment (ROI)

Most facilities that switch to LED high bay lighting recover their investment within 1 to 3 years, depending on energy rates and usage patterns. Rebates from utility companies or local energy programs can help speed up ROI even further.

Long-Term Value

After the payback period, continued energy savings and reduced maintenance lead to real bottom-line improvements. LEDs also support sustainability goals by cutting carbon emissions and using non-toxic, recyclable materials.

In short, retrofitting to LED high bay lights may require some upfront planning and cost, but the long-term financial and operational benefits are well worth the effort.

Step-by-Step Guide to Retrofitting High Bay Lights with LEDs

Upgrading your facility to LED high bay lighting is a practical move that boosts efficiency and lowers long-term costs. Here’s a clear step-by-step guide to help you through the retrofitting process:

1. Assess Current Lighting

Start by inspecting your existing lighting setup. Note the number of fixtures, their wattage, mounting height, and the type of light output. Determine the lighting levels your space requires and identify any areas with uneven coverage or dark spots. This step helps you decide how many LED fixtures you’ll need and what brightness level to target.

2. Select Appropriate LED Fixtures

Choose LED high bay lights that match your needs for brightness (lumens), energy efficiency (lumens per watt), and color temperature. Make sure to pick fixtures that fit your ceiling height and application—such as UFO lights for open areas or linear high bays for aisles. Also, confirm that the new LED fixtures are compatible with your existing power supply.

3. Plan Installation

Determine how the new lights will be mounted—chain mount, hook mount, or surface mount. Check for any special installation requirements and make sure your electrical system can handle the new fixtures. If needed, plan for additional wiring or modifications. This is also a good time to decide whether you want to include features like dimming, motion sensors, or smart controls.

4. Install Fixtures

Safely remove the old fixtures and dispose of them according to local regulations. Install the new LED high bay lights, following the manufacturer’s instructions. Make sure all electrical connections are secure and test each fixture during installation to catch any issues early.

5. Test and Adjust

Once all fixtures are installed, turn on the lighting system and inspect the coverage. Check for any uneven lighting, glare, or shadows. If needed, adjust the angle or placement of the lights to improve performance. Test any additional controls or sensors to ensure they function correctly.

By following these steps, you can ensure a smooth transition to LED high bay lighting, resulting in better performance, energy savings, and reduced maintenance for your facility.

Safety Precautions During Installation

Safety should always be the top priority when installing or retrofitting LED high bay lights. These fixtures are often mounted at significant heights and involve electrical work, so extra care is necessary to avoid accidents or damage. Here are key precautions to follow:

Turn Off Power at the Source

Before starting any work, make sure the power to the area is completely shut off at the circuit breaker. Never assume a fixture is safe just because the light is off. Use a voltage tester to confirm there is no live current before handling wires or fixtures.

Use Proper Personal Protective Equipment (PPE)

Always wear the right safety gear for the job. This includes safety glasses, insulated gloves, hard hats, and non-slip footwear. If you’re working on a ladder or lift, use a safety harness and ensure the equipment is stable before climbing.

Ensure Secure Working Conditions

When working at heights, use ladders or lifts rated for your weight and tools. Place them on a flat, stable surface, and never overreach while working overhead. If using a lift, follow all operating guidelines and wear a fall arrest system if required.

Follow Manufacturer Instructions

Each LED fixture may have different installation requirements. Always read and follow the manufacturer’s installation manual to ensure proper handling, wiring, and mounting. Using incorrect tools or skipping steps can lead to poor performance or even fixture failure.

Check for Compatibility

Make sure the new LED lights are compatible with your existing electrical system, including voltage, circuit load, and any connected controls. Incorrect connections can cause flickering, overheating, or circuit damage.

Secure All Wiring and Mounting Hardware

Use proper wire connectors and strain relief fittings to secure electrical connections. All mounting brackets, hooks, or chains should be rated to support the weight of the fixture and tightened securely to prevent any movement or sagging.

Consult a Licensed Electrician

If you’re unsure about any part of the process—especially wiring or code compliance—it’s best to bring in a qualified electrician. They can ensure the installation meets local safety codes and operates reliably without risk.

Taking these precautions during installation helps ensure the safety of everyone involved and guarantees that your LED high bay lighting system functions efficiently and safely.

Maintenance Tips for LED High Bay Lights

LED high bay lights are known for their durability and low maintenance needs, but routine care helps keep them performing at their best. Here are simple maintenance tips to extend their lifespan and ensure consistent performance:

Regular Cleaning

Dust, dirt, and debris can collect on the surface of the fixture, reducing light output over time. Clean the lenses and housing regularly using a soft, dry cloth or a damp cloth with mild soap if needed. Avoid harsh chemicals that can damage the surface or lenses. Keeping the lights clean ensures maximum brightness and efficiency.

Periodic Inspections

Even though LED lights last a long time, it’s important to inspect them occasionally. Look for signs of wear such as flickering, discoloration, loose wires, or corrosion around connections. Check mounting brackets and ensure the fixture is still securely attached. Early detection of issues can prevent bigger problems later.

Check for Overheating

Make sure the fixture’s heat sinks are free of obstructions. Good airflow around the driver and LED chips is crucial to prevent overheating, especially in high-heat environments. If lights are installed in dusty or high-temperature areas, inspect them more often.

Test Control Features

If your high bay lights have dimming features, motion sensors, or smart controls, test them periodically to confirm they’re working correctly. Replace batteries in wireless sensors if needed and recalibrate motion detection settings if performance changes.

Firmware Updates (for Smart Fixtures)

Some modern LED high bay lights come with smart features controlled through apps or automation systems. When updates are available, apply firmware upgrades to benefit from improved performance, added features, or bug fixes. Always follow the manufacturer’s instructions for updating.

By following these maintenance steps, you’ll keep your LED high bay lights running efficiently, reduce the chance of failures, and maintain a safe, well-lit environment.

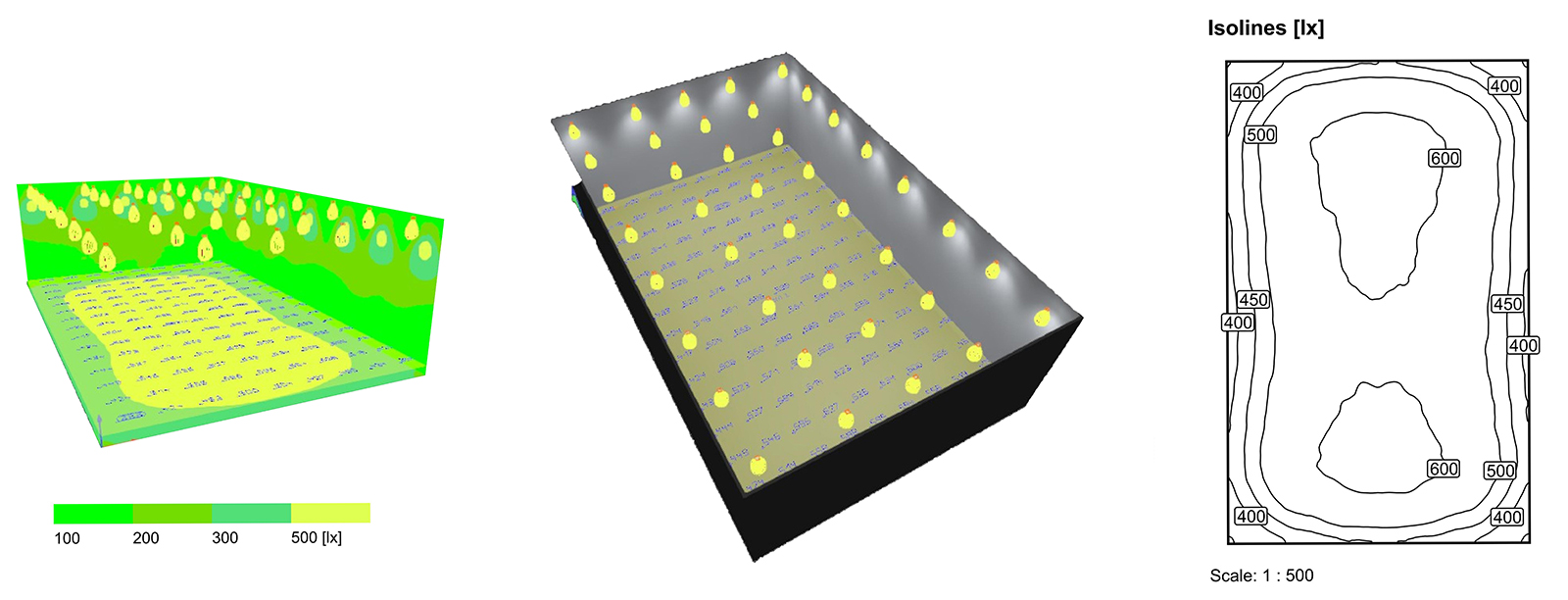

Design a Layout for Your High Bay Lights

A well-planned lighting layout is essential to ensure your facility is evenly lit, energy-efficient, and meets all safety and productivity needs. Simply installing lights without a strategy can lead to dark spots, glare, or wasted energy. Here’s how to design an effective layout for your LED high bay lights:

Measure Your Space

Start by recording the length, width, and height of your facility. The ceiling height plays a major role in determining the type of light fixture and beam angle needed. Higher ceilings may require more powerful lights or narrower beam angles to focus light downward.

Determine Lighting Requirements

Each space has different lighting needs depending on its use. Warehouses, manufacturing areas, and gymnasiums often require different light levels measured in lux. For example, general warehouse areas may need 150–300 lux, while task-specific zones may need 400–500 lux or more.

Choose the Right Fixture Type

Based on your layout, decide whether you need UFO-style lights for open spaces or linear high bay lights for aisles and corridors. The shape and purpose of the space will guide this choice.

Use a Lighting Calculator

A high bay lighting calculator helps you determine the optimal number of fixtures and their placement. Input your ceiling height, room dimensions, desired lux level, and fixture specifications. The calculator provides a layout that minimizes overlap while ensuring full coverage.

Plan Fixture Spacing

Even spacing is key to avoiding bright spots and dark corners. Typically, high bay lights are spaced 1 to 1.5 times the mounting height apart. For example, if your fixtures are mounted at 10 meters, spacing them 10 to 15 meters apart is a good starting point. Adjust as needed based on beam angle and room shape.

Consider Obstructions and Layout Features

Account for shelving, machinery, or other tall structures that may block light. You may need additional fixtures in areas with obstructions to maintain even illumination. Also, consider emergency lighting zones, exits, or special task areas that might require focused light.

Test and Adjust

Once installed, evaluate the layout and make adjustments if necessary. You may need to fine-tune angles or reposition fixtures slightly to avoid shadows or glare.

Designing your high bay lighting layout with these steps ensures bright, uniform light across your facility—improving visibility, safety, and energy performance.

FAQs About LED High Bay Lights

What distinguishes high bay lights from low bay lights?

High bay lights are designed for use in spaces with ceilings higher than 6 meters. They deliver powerful, focused illumination needed to light up large vertical areas. In contrast, low bay lights are intended for ceilings under 6 meters and provide a wider light spread with less intensity.

How do I determine the number of fixtures needed for my space?

The number of LED high bay lights you need depends on several factors, including the total area size, ceiling height, and desired brightness level (measured in lux). You can use a high bay lighting calculator or consult with a lighting specialist to create an efficient and accurate lighting layout.

Can LED high bay lights be used in outdoor settings?

Yes, some LED high bay lights are suitable for outdoor use, but only if they have the correct IP (Ingress Protection) rating. For outdoor or damp environments, look for fixtures rated at least IP65, which protects against water and dust.

What is the typical lifespan of an LED high bay light?

Most quality LED high bay lights have a lifespan between 50,000 and 100,000 hours. Actual longevity depends on the operating environment, installation quality, and whether the lights are run continuously or intermittently.

Are there smart control options available for LED high bay lights?

Yes, many LED high bay lights are compatible with smart control systems. These include features like motion sensing, daylight harvesting, wireless dimming, and scheduling. Using smart controls not only adds convenience but also helps reduce energy use by adjusting light levels based on real-time conditions.

Conclusion

In conclusion, selecting the right LED high bay lights involves understanding your specific lighting needs and the various options available. By considering factors like lumen output, fixture type, and application environment, you can make informed decisions that enhance both efficiency and illumination quality. If you have further questions or need assistance in choosing the best lighting solutions for your facility, feel free to contact us directly.