Flickering tubes, high energy bills, and constant maintenance—fluorescent lighting can be a real headache. These issues not only disrupt operations but also lead to increased costs and inefficiencies. Fortunately, converting to LED lighting offers a reliable solution, enhancing performance and reducing expenses.

Converting fluorescent lights to LED involves replacing outdated tubes with energy-efficient LED alternatives. This process can be accomplished through methods like ballast bypass or using plug-and-play LED tubes, depending on your existing fixtures. The benefits include improved energy efficiency, longer lifespan, and reduced maintenance costs, making it a worthwhile investment for businesses.

Let’s delve deeper into the specifics of this conversion process and explore the advantages it brings.

Table of Contents

The Issues with Fluorescent Fixtures

Fluorescent fixtures were once the standard choice for commercial and industrial lighting, but they come with a number of drawbacks that have become more apparent over time.

1. Flickering and Buzzing

One of the most common problems is flickering, which can be irritating and even trigger headaches or eye strain for workers. Older ballasts often create a noticeable buzzing sound, especially as they age.

2. Delayed Start-Up

Unlike LEDs, fluorescent lights don’t turn on instantly. Many require a warm-up period, especially in cold environments, which can delay operations or frustrate users.

3. Declining Brightness

Over time, fluorescent tubes tend to lose brightness. This means the space becomes dimmer even though the light is still functioning, reducing visibility and productivity.

4. Hazardous Materials

Fluorescent tubes contain small amounts of mercury. If broken, this can be hazardous to both health and the environment. Disposal of these lamps requires special handling to prevent contamination.

5. Higher Energy Use

Fluorescent fixtures consume more power than modern LED equivalents. This leads to higher utility bills, especially in facilities where lights are on for extended periods.

6. Shorter Lifespan and More Maintenance

Fluorescent tubes have a much shorter lifespan than LED lights. Frequent replacements not only cost more in materials but also require more labor to maintain, disrupting daily operations.

7. Incompatibility with Smart Controls

Most fluorescent systems are not compatible with dimming, motion sensors, or other smart controls without expensive upgrades.

For these reasons, more businesses are moving away from fluorescent lighting and switching to LED solutions, which offer better performance, safety, and energy savings.

LED tube light Application in supermarket

How to Convert Fluorescent to LED?

Switching from fluorescent to LED lighting can be done using two main methods, depending on your existing setup and goals:

1. Ballast Bypass (Direct Wire)

This is the most energy-efficient and long-term option.

- How it works: You remove the existing ballast from the fixture and wire the LED tubes directly to the power source.

- Compatible with: Type B LED tubes, also known as direct wire or ballast-bypass tubes.

- Pros:

- Eliminates the ballast, reducing potential points of failure.

- Lower long-term maintenance and energy costs.

- Works even if the original ballast is broken.

- Cons:

- Requires basic rewiring, usually done by an electrician.

2. Plug-and-Play (Ballast Compatible)

This is the fastest and easiest method if your fixture has a working electronic ballast.

- How it works: You install Type A LED tubes directly into the existing fixture without modifying the wiring.

- Compatible with: Electronic ballasts only—not magnetic.

- Pros:

- No rewiring required.

- Quick and simple installation.

- Cons:

- Still depends on the lifespan and performance of the existing ballast.

- Less efficient than a direct wire setup.

Which Method Should You Choose?

- For quick upgrades: Plug-and-play (Type A) is the way to go, especially for large facilities needing fast rollouts.

- For maximum efficiency and fewer maintenance issues: Ballast bypass (Type B) is the better long-term investment.

Before converting, always check your current ballast type and fixture compatibility. Some LED tubes also support hybrid functions (Type A+B), allowing plug-and-play use now with the option to bypass the ballast later.

Types of LED Tubes

Benefits of Replacing Fluorescent Tube with LED

Switching to LED lighting offers numerous advantages:

- Energy Efficiency: LEDs consume significantly less power, leading to lower electricity bills.

- Longer Lifespan: LED tubes can last up to 50,000 hours, reducing the frequency of replacements.

- Improved Light Quality: LEDs provide consistent, flicker-free illumination with better color rendering.

- Environmental Benefits: LEDs contain no hazardous materials like mercury, making them safer and more eco-friendly.

- Reduced Maintenance: The durability and longevity of LEDs minimize maintenance efforts and costs.

Cost to Convert Fluorescents to LED

The cost of converting fluorescent fixtures to LED varies based on factors such as the number of fixtures, chosen conversion method, and labor expenses. While plug-and-play installations may have lower upfront costs, ballast bypass conversions often result in greater long-term savings due to improved energy efficiency. It’s advisable to conduct a cost-benefit analysis to determine the most economical approach for your specific situation.

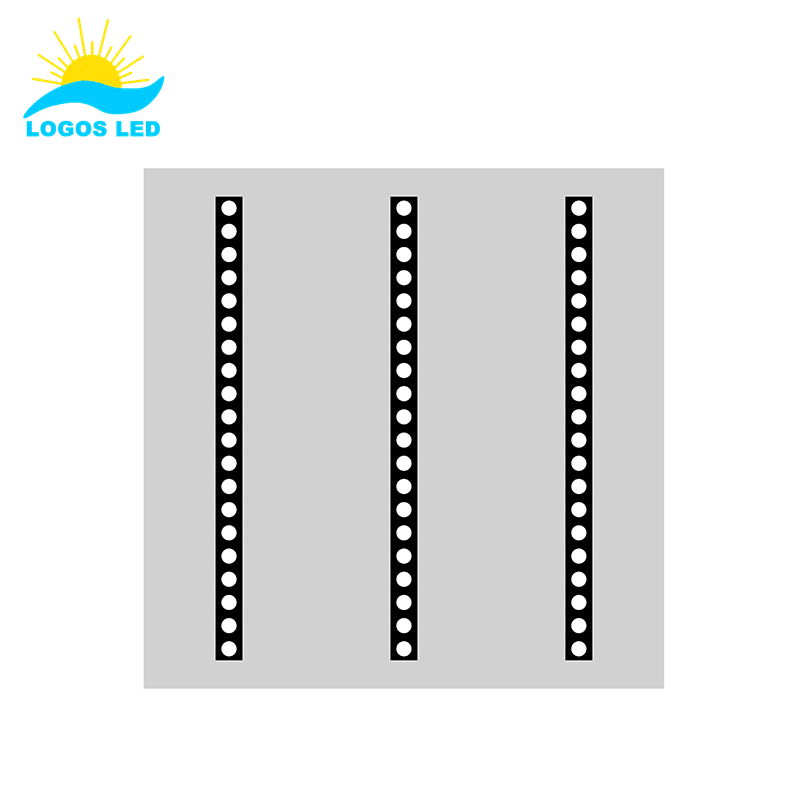

LED Tube Light

How to Rewire LED without Ballast?

If you’re switching to Type B LED tubes that require no ballast, here’s how to rewire your fixture:

1. Turn Off Power

Safety first. Go to your breaker panel and turn off the circuit connected to the fixture. Use a voltage tester to confirm there’s no power.

2. Remove the Ballast

Open the light fixture and locate the ballast (usually a rectangular box inside). Disconnect all wires connected to the ballast and remove it from the fixture.

3. Rewire the Fixture

Now connect your AC power (typically black for live and white for neutral) directly to the lampholders (tombstones). Follow the wiring diagram provided with your LED tube. Most tubes require either single-ended or double-ended wiring:

– Single-ended tubes: Power goes to one side only (live and neutral on the same end).

– Double-ended tubes: Live on one end, neutral on the other.

4. Install LED Tubes

Place the LED tubes into the rewired lamp holders. Make sure they are compatible with the new wiring setup.

5. Restore Power

Turn the circuit breaker back on. Flip the light switch to test your installation.

If you’re unfamiliar with wiring or don’t feel confident, always contact a licensed electrician. It’s better to be safe and ensure everything is done to code.

FAQs about Converting Fluorescent to LED

Can I directly replace fluorescent tubes with LED?

Yes, but only if you’re using plug-and-play (Type A) LED tubes that are compatible with your existing electronic ballast. This allows for a quick swap without rewiring. For better energy efficiency and reliability, a ballast bypass (Type B) is usually the smarter long-term choice.

Do I need to remove the ballast to use an LED bulb?

Not always. Some LED tubes work with the existing ballast. But if you want fewer parts that can fail, bypassing the ballast eliminates an extra power draw and maintenance concern.

Can I put LED bulbs in a fluorescent ballast?

Only if the LED tubes are labeled as ballast-compatible. Forcing a non-compatible LED into a fluorescent ballast setup can cause flickering, failure, or even electrical damage.

How do I know if my ballast is compatible with LED?

Check your ballast label and compare it to the LED manufacturer’s compatibility list. Most reputable LED brands provide charts or documentation showing which ballasts work with their tubes.

Is it worth replacing fluorescent tubes with LED?

Yes, 100%. You’ll save energy, reduce maintenance, get better light quality, and eliminate issues like flicker or slow start times. LEDs also last far longer—often 5 to 10 times longer than fluorescents.

LED Tube Light Applications

Conclusion

Converting fluorescent lighting to LED is a practical step toward improved energy efficiency, better lighting quality, and reduced operational costs. By understanding the conversion methods and benefits, businesses can make informed decisions that align with their goals and resources.

If you have any questions or need assistance with your lighting conversion project, feel free to reach out to us at Logos Lighting.

Request A Free Quote Now!

Send us a message if you have any questions or request a quote. We will get back to you ASAP!