Standard LED shop lights can ignite flammable gases in hazardous areas, leading to catastrophic explosions. To prevent such disasters, explosion-proof lighting is essential.

LED shop lights are not inherently explosion-proof. Explosion-proof lights are specially designed to contain sparks and prevent ignition in hazardous environments. They are constructed with robust materials and meet specific safety standards. For areas with flammable gases or dust, using certified explosion-proof lighting is crucial to ensure safety.

Understanding the differences between standard and explosion-proof lighting is vital for workplace safety.

Table of Contents

What Are LED Shop Lights?

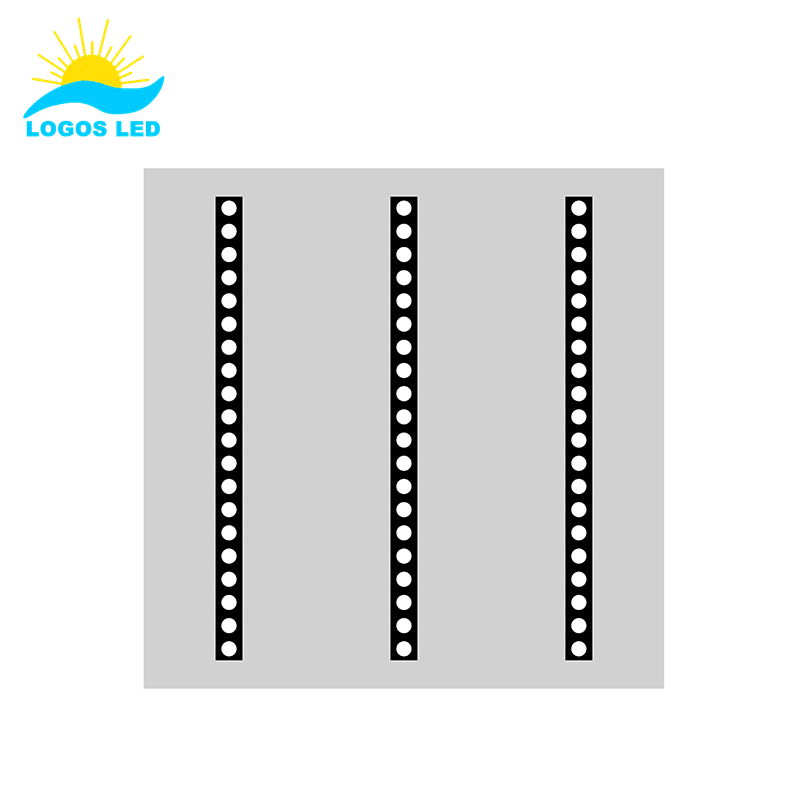

LED shop lights are linear or round style lighting fixtures designed for use in workshops, garages, basements, and commercial spaces. They deliver high brightness with minimal energy use, making them a popular upgrade from traditional fluorescent fixtures.

These lights typically come in 2-foot, 4-foot, or 8-foot lengths and are often mounted to ceilings or suspended by chains. Their uniform light output makes them ideal for task lighting, tool work, or general ambient lighting in workspaces.

LED shop lights feature long lifespans—often exceeding 50,000 hours—and require little to no maintenance. They turn on instantly, produce very little heat, and operate without flicker, which enhances comfort and productivity.

However, they are not suitable for environments with explosive gases, dust, or chemicals. For those conditions, explosion-proof or vapor-tight LED fixtures should be used instead.

LED shop lights are an easy and cost-effective way to brighten up work areas while cutting down on energy bills and maintenance efforts.

What Are Hazardous Location Lights?

Hazardous location lights are specially engineered fixtures designed to operate safely in environments where explosive gases, vapors, or combustible dust are present. These areas are typically found in oil refineries, chemical plants, grain silos, and industrial processing facilities.

The key feature of hazardous location lighting is its ability to contain any sparks or heat generated by the fixture. This prevents ignition of surrounding hazardous substances. The lights are constructed with sealed, heavy-duty housings and use materials that can withstand extreme temperatures, vibration, and corrosion.

These lights must meet strict safety certifications to ensure compliance with regional and international standards. Two common classifications include:

- Class I Division 1: For locations where flammable gases or vapors are present continuously or frequently under normal operating conditions.

- Class II Division 1: For areas where combustible dust is regularly present in the air during normal operation.

Choosing the right classification is critical for safety and legal compliance. Hazardous location LED lights also provide benefits like energy efficiency, long life, and reduced maintenance, making them a reliable and cost-effective choice for high-risk work environments.

Are LED Shop Lights Explosion Proof?

Standard LED shop lights are not explosion-proof. To be explosion-proof, a light fixture must meet specific design criteria and certifications. Explosion-proof LED lights are available and are designed to operate safely in hazardous environments. It’s crucial to select the appropriate lighting based on the specific hazards present in the area.

What Class Is Explosion Proof Lighting?

Explosion-proof lighting is categorized by the type of hazardous environment it is intended for. These classifications help ensure that the lighting fixtures can safely operate without igniting surrounding flammable materials. Here’s how the system works:

- Class I: This class covers areas where flammable gases or vapors may be present. Common locations include oil refineries, gas stations, and chemical plants.

-

Class II: This class is for areas where combustible dust is present. These environments include grain silos, flour mills, and metal processing facilities.

-

Class III: This class applies to places where ignitable fibers or flyings are found, such as textile mills, woodworking facilities, and certain manufacturing zones.

Each class is broken down further into Divisions:

- Division 1: Hazardous material is present during normal operations.

- Division 2: Hazardous material is present only during abnormal conditions (like leaks or system failures).

Additionally, Groups (such as Group A, B, C, D for gases and Group E, F, G for dust) further define the specific type of hazardous substance the fixture is built to withstand.

Selecting the correct Class, Division, and Group ensures compliance with safety standards and minimizes the risk of fire or explosion in dangerous environments.

Benefits and Application of Explosion Proof Lights

Explosion-proof lights are essential in environments where flammable gases, vapors, dust, or fibers are present. Their construction is designed to contain any internal explosion, preventing it from igniting the surrounding atmosphere. Here are the key benefits and typical applications:

Benefits

- Safety: The primary benefit is safety. These lights are sealed and reinforced to prevent sparks or high heat from igniting hazardous materials in the air.

-

Durability: Explosion-proof fixtures are made from tough materials like aluminum or stainless steel, with thick tempered glass. They resist corrosion, impacts, and extreme temperatures.

-

Compliance: These lights meet stringent international safety codes such as ATEX, IECEx, and North American standards (Class I, II, III; Divisions 1 and 2). Using certified lighting helps facilities stay compliant with local regulations and insurance requirements.

-

Efficiency: Many explosion-proof lights now use LED technology, offering bright light output with lower energy consumption. LEDs also produce less heat, further reducing risk in sensitive environments.

Applications

Explosion-proof lighting is widely used in hazardous and industrial locations where safety is critical:

- Oil and Gas Facilities: Including drilling rigs, refineries, and fuel storage areas.

- Chemical Plants: Where volatile vapors or corrosive chemicals are handled.

- Mining Operations: Underground or surface mining sites with potential gas leaks or dust accumulation.

- Grain Silos and Processing Plants: Where fine combustible dust can create an explosive atmosphere.

- Paint Booths and Spray Areas: Environments with flammable fumes and particles.

- Pharmaceutical Manufacturing: Clean rooms or production lines involving volatile substances.

By choosing explosion-proof lighting, these industries ensure reliable illumination without compromising on worker safety or regulatory compliance.

Is it a fire hazard to leave LED lights on?

LED lights generate less heat than traditional bulbs, reducing fire risk. However, leaving any electrical device on unattended can pose a fire hazard if the fixture is faulty or improperly installed. Regular maintenance and using certified fixtures minimize risks.

Are LED lights safe overnight?

LED lights are generally safe to use overnight due to their low heat output and energy efficiency. Ensure the fixtures are in good condition and installed correctly. Using timers or motion sensors can also enhance safety and energy savings.

Do LED lights get hot enough to melt plastic?

LED lights produce minimal heat compared to incandescent bulbs. Under normal operation, they should not get hot enough to melt plastic. However, poor-quality fixtures or improper installation can lead to overheating. Always use high-quality, certified LED fixtures to prevent such issues.

Conclusion

While standard LED shop lights are not explosion-proof, specialized explosion-proof LED fixtures are available for hazardous environments. Selecting the appropriate lighting ensures safety, compliance, and efficiency in your operations.

For expert advice and high-quality explosion-proof lighting solutions, just feel free to contact us directly. Our lighting experts are ready to help.

Request A Free Quote Now!

Send us a message if you have any questions or request a quote. We will get back to you ASAP!