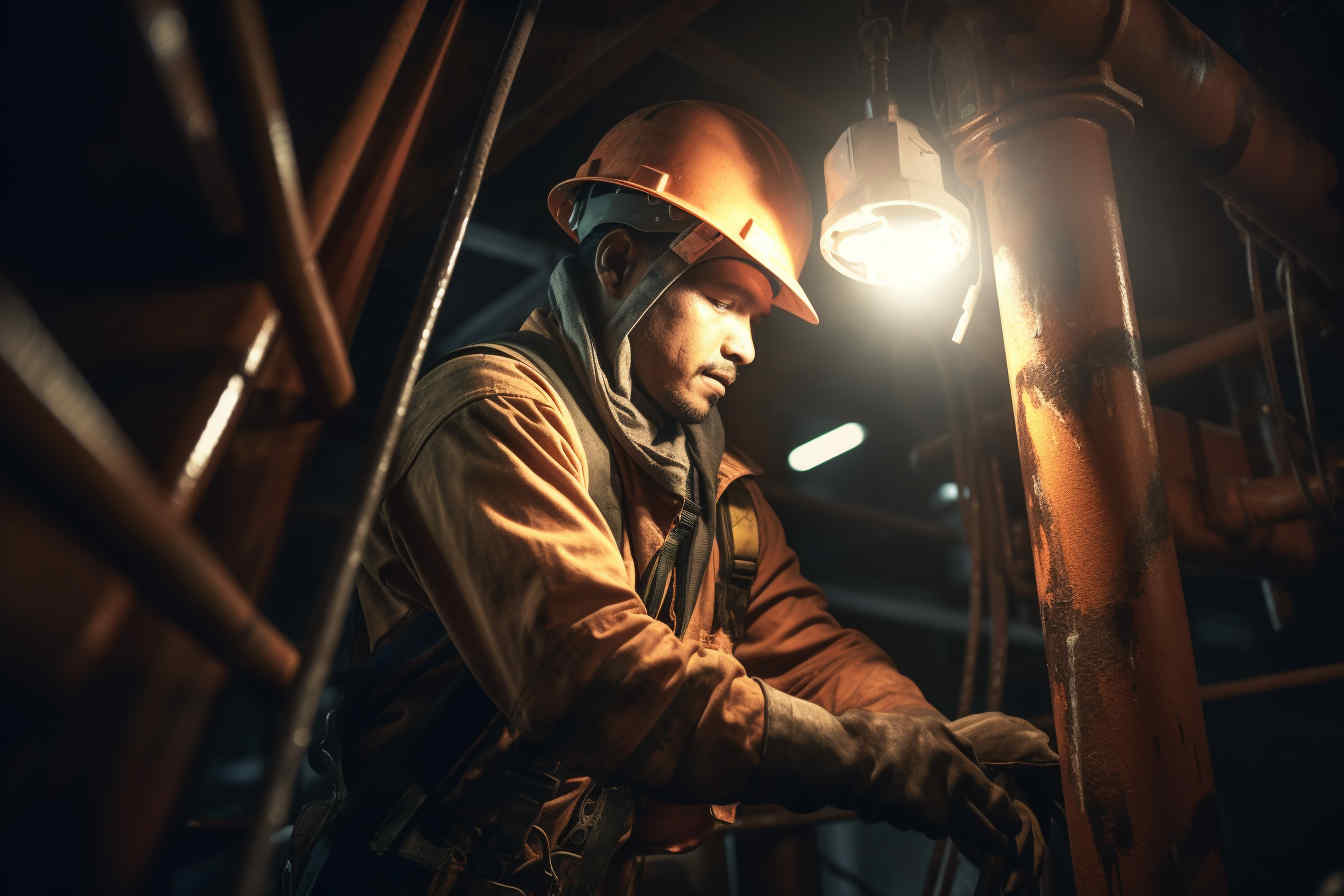

Poor lighting on oil rigs creates danger, increases downtime, and puts workers at risk. Safety issues grow fast without proper illumination. The solution? Reliable oil rig lighting.

Oil rig lighting is essential for safety, efficiency, and 24/7 operations in offshore environments. It ensures visibility, prevents accidents, and supports productivity during night shifts. Proper lighting also serves as a navigational aid, assists in emergency responses, and reduces environmental impact when designed with energy-efficient fixtures. Explosion proof lights, floodlights, crane lights, and pole-mounted fixtures are commonly used to meet strict safety and performance standards in harsh oil rig conditions.

Let’s go deeper into why oil rig lighting matters and how to design it right.

Table of Contents

Lighting Requirements for Oil Rig Lighting

Oil rigs are complex, high-risk environments where proper lighting is not just a convenience—it is a necessity for survival and safety. Because these facilities operate 24/7 in offshore locations, lighting must be designed to meet strict international safety and performance standards.

Fixtures must be built to withstand constant exposure to harsh marine conditions. Saltwater spray, strong winds, high humidity, and extreme temperatures all contribute to corrosion and wear. This is why most oil rig lighting uses marine-grade aluminum housings with special anti-corrosion coatings, tempered glass covers, and stainless-steel fittings. Vibration resistance is equally important since heavy drilling machinery and equipment create constant shaking that can damage poorly designed fixtures.

Lighting levels must comply with international standards such as ATEX, IECEx, or UL844 for hazardous locations. Minimum lux requirements vary depending on the work zone—for example, walkways and general working areas often need 50–200 lux, while precision task zones require 300 lux or more. Emergency lighting systems are mandatory, providing reliable illumination during power failures to guide workers safely to muster stations and evacuation points.

Because oil rigs are energy-intensive operations, efficiency also matters. High-performance LED fixtures are preferred as they cut power use by up to 70% compared to traditional HID or fluorescent lamps. This not only reduces fuel consumption for onboard generators but also lowers heat emissions, making the environment safer.

Well-designed oil rig lighting systems help reduce downtime by improving visibility during operations, boosting worker confidence when performing dangerous tasks, and ensuring full compliance with safety and environmental standards. In such critical environments, the right lighting truly saves lives.

How Oil Rig Lighting Enhances Operations?

Ensuring Visibility and Minimizing Accidents

Oil rigs are filled with walkways, staircases, platforms, and equipment that pose risks if not properly lit. Adequate lighting reduces the chances of slips, trips, and falls—the most common causes of injuries offshore. When decks and workstations are illuminated evenly, workers can see tools, machinery, and potential hazards clearly. This allows them to handle heavy equipment and perform delicate tasks with greater confidence and accuracy, keeping operations safe and efficient.

Navigational Aid and Emergency Response

Lighting on oil rigs does more than support workers—it also plays a key role in navigation. Powerful pole-mounted floodlights provide visibility for supply vessels and helicopters approaching the rig at night or in poor weather conditions. In emergencies, bright lighting helps guide evacuation routes, ensuring workers can quickly and safely reach muster points. Rescue teams also rely on strong illumination to locate and assist personnel during critical situations. Without this, response times could be delayed, putting lives at risk.

Night Shift Operations and 24/7 Productivity

Oil rigs operate non-stop, and night shifts are a normal part of offshore life. Proper illumination ensures workers can maintain the same level of productivity at night as they do during the day. High-quality LED fixtures provide stable, flicker-free light that reduces eye strain and fatigue, helping crew members stay alert. This minimizes costly errors, improves decision-making, and supports continuous drilling, maintenance, and safety checks without interruption.

Environmental Considerations and Energy Efficiency

Running an oil rig consumes vast amounts of energy, so lighting must be efficient as well as effective. LED technology is now the standard choice because it reduces energy consumption by up to 70% compared to traditional metal halide or fluorescent fixtures. LEDs also last much longer, lowering replacement and maintenance costs. Beyond cost savings, modern LED designs reduce light spill and minimize glare, helping to protect nearby marine ecosystems from unnecessary disruption. This balance of safety, efficiency, and environmental responsibility makes LED lighting an essential part of modern offshore operations.

Types of Oil Rig Lights

Explosion Proof Fixtures

Explosion proof fixtures are the backbone of oil rig safety. These lights are specifically engineered for hazardous zones where flammable gases, vapors, and dust are common. Instead of allowing sparks or heat to escape, their reinforced housing contains any ignition source inside the fixture. This design prevents explosions from occurring in volatile environments. They are commonly found near drilling equipment, pump rooms, and storage areas, where the risk of gas leaks is highest. By meeting strict safety certifications, explosion proof lights ensure compliance with international offshore safety standards.

Flood Lights

Flood lights are critical for keeping large open areas on the rig well-lit. Mounted on structures or poles, they cast broad beams of high-intensity light across decks, walkways, and work platforms. During harsh conditions like storms, fog, or nighttime operations, flood lights ensure that every corner of the rig is visible. Workers can spot hazards quickly, machinery can be operated safely, and emergency procedures can be carried out without delay. Their ability to resist vibration, saltwater, and extreme weather makes them a must-have for offshore environments.

Crane Safety Lights

Cranes are one of the most active and dangerous pieces of equipment on an oil rig. Crane safety lights are used to mark the movement of cranes, alerting crew members nearby. These lights create visible zones around the crane, reducing the chance of collisions or accidents. For crane operators, safety lights enhance visibility of the boom and load, especially in low-light conditions. This not only increases operational efficiency but also significantly reduces the risk of injury to workers operating in close proximity.

Pole Mounted Lights

Pole-mounted lights provide overhead illumination that covers wide areas, minimizing shadows and dark zones. They are strategically placed at elevated points around the rig to give a bird’s-eye distribution of light across work areas, pathways, and storage zones. Their height allows them to illuminate large sections at once, improving visibility for both routine operations and emergency situations. By reducing blind spots, pole-mounted lights enhance navigation for workers and incoming vessels, creating a safer and more productive environment on the rig.

Conclusion

Oil rig lighting is more than illumination—it’s a safety system, a productivity booster, and a lifeline in emergencies. With the right mix of explosion proof fixtures, floodlights, crane lights, and energy-efficient LEDs, rigs can run smoothly and safely around the clock.

If you’re planning an oil rig lighting upgrade or need expert guidance, contact Logos Lighting today—we’ll help you get it right.

Request A Free Quote Now!

Send us a message if you have any questions or request a quote. We will get back to you ASAP!