Have you ever bought LED lights that looked great at first but quickly dimmed, flickered, or failed entirely? Inefficient manufacturing processes and poor-quality materials can leave businesses frustrated and losing money. Fortunately, understanding the production process, proper materials, and testing standards will help you choose reliable LED lighting fixtures.

LED lights go through a careful manufacturing process, including wafer fabrication, assembly of essential components like LED chips, lenses, and housing, thermal management design, and rigorous testing to international quality standards such as EMC, LVD, LM-79 and LM-80, tec. Premium manufacturers use high-grade materials like aluminum heat sinks, quality LED chips, and durable drivers. Ensuring these strict controls results in reliable, energy-efficient, and sustainable lighting solutions suitable for commercial and industrial applications that last longer and perform better, saving you considerable maintenance and operating costs in the long run.

Let’s dig deeper into each step, so you can clearly understand the factors behind a reliable lighting product.

Table of Contents

What Exactly Is an LED Chip?

Think of the LED chip like the brain inside the LED lighting. This tiny component is usually made from semiconductor materials, often gallium arsenide or gallium phosphide. In the LED chip fabrication process, these materials are grown as crystals and then sliced into thin wafers. Layers are deposited onto these wafers to create what’s called a semiconductor junction. Electricity passes through this junction, causing electrons to move and energy to be released as visible light. Companies such as Lumileds, Osram, or Seoul are reputable suppliers of high-quality LED chips, ensuring better performance and longer lifespan.

What Components and Materials Are Used in LED Lights?

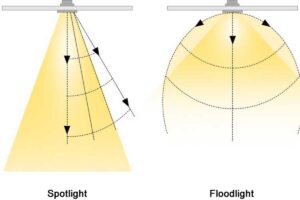

LED lights consist of several important parts and materials to function effectively. Besides the semiconductor chip itself, each LED lighting fixture requires components such as lenses for focusing and distributing light, circuit boards to connect electrical parts, aluminum heat sinks used for thermal management, and housing made from durable plastics or aluminum. Quality LED lighting suppliers commonly source drivers from brands like Philips or Meanwell, known for reliability. All these materials combined define the durability and performance of the LED fixture, influencing the product’s lifespan and lighting efficiency.

What Are the Main Steps in the LED Manufacturing Process?

The LED manufacturing process involves several key steps. Initially, semiconductor crystals are grown and cut into thin wafers, creating the LED chips. These wafers then undergo processes such as doping and layering to form essential electrical connections. Next, the chips are attached to a circuit board, where electrical leads are soldered in place.

Following this, the chips are mounted onto suitable heat sinks, ensuring efficient thermal management to prevent overheating. Proper thermal design is critical in maintaining LED performance. Protective lenses and covers are then applied, and the entire fixture is assembled into a complete unit.

Finally, comprehensive testing is conducted to ensure that all components meet strict quality standards, maintaining uniform brightness, color accuracy, and reliability across all products. This process involves rigorous inspections at various stages to adhere to international quality benchmarks.

LED High Bay Light Assembly Process

Why Is Thermal Management So Important in LED Lighting?

Managing heat is crucial for LED lights, as excess heat can severely reduce their lifespan and efficiency. Heat sinks or aluminum housings are typically used in thermal management. These parts transfer heat away from the sensitive LED chips. When thermal management is overlooked, LEDs may quickly lose brightness or stop working entirely. Good thermal design is essential for professional-grade LED lighting because it ensures stable luminance, protects delicate internal components, and prevents premature failure, giving you reliable performance and longer-lasting products.

Lifetime of Lumileds LUXEON 5050

What Quality Standards Should LED Lights Meet?

LED lights must meet various quality standards to ensure they perform reliably and safely. One crucial aspect is compliance with Electromagnetic Compatibility (EMC) standards. This ensures that LED lights do not emit electromagnetic interference that could affect other devices. EMC testing is performed to validate that the light, along with its driver, complies with regulatory requirements.

Another important standard is the Low Voltage Directive (LVD), which ensures the safety of electrical equipment within certain voltage limits. LVD testing evaluates the safety aspects, such as electrical and mechanical construction, to prevent hazards. It’s vital that LED lights undergo these tests to secure a CE mark, an indication that the product meets all EU requirements.

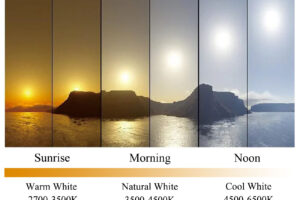

Quality control also involves rigorous performance testing of the lights. LM-79 and LM-80 are two essential testing standards. LM-79 measures the overall performance of the complete fixture, evaluating factors like brightness, color, and efficiency. LM-80 focuses on the LED chip performance over time, providing valuable data on life expectancy and lumen maintenance. By meeting these standards, manufacturers assure that their lights will consistently fulfill performance expectations, leading to fewer replacements and enhancing reliability.

Quality standards also emphasize environmental and operational efficiency. For example, testing for flicker-free performance and achieving a high power factor is important, as these aspects ensure the lights operate smoothly and efficiently. Additionally, durability standards, like IP ratings, are assessed to guarantee the lights’ protection against dust and water, ensuring longevity in various environments.

In summary, conforming to EMC and LVD standards, coupled with rigorous testing like LM-79 and LM-80, ensures LED lights are safe, efficient, and reliable. This helps reassure buyers of the product’s quality and long-term performance.

Photometric Testing

What’s Involved in Sustainable LED Manufacturing?

Sustainable practices help reduce environmental impact throughout LED manufacturing. Environmentally conscious manufacturers seek out sustainable raw materials, use highly efficient, energy-saving machinery, and reduce waste in production lines. Additionally, packaging and transporting are planned carefully to minimize carbon footprints. Sustainable LED manufacturing not only helps protect our planet but also delivers products that qualify for certain environmental certifications and regulations. For both you and your customers, choosing sustainably produced LED lights demonstrates responsible business practices and offers advantages in eco-conscious markets.

How Do I Know If My LED Lights Use Quality Materials?

Identifying quality materials can sometimes be tricky. Reliable brands like Lumileds, Osram, Philips, and Meanwell are well-known for their durability. Reputable manufacturers clearly list the components and provide datasheets and certifications to prove the source of their parts. You can request testing certificates, inquire directly with your LED lighting solutions suppliers, or review case studies that showcase proven durability. Partnering with reputable suppliers like Logos Lighting offers transparency and ensures you’ll get dependable, top-quality lighting fixtures, backed by clear warranty terms.

How Do Manufacturers Ensure Consistent Product Quality?

Manufacturers ensure consistent product quality by selecting trusted materials and components from reputable brands such as Philips, Osram, and Mean Well. This choice guarantees top performance. Regular inspections and testing during production are crucial, led by experienced quality control managers who oversee the process to minimize errors. Automated production lines play a significant role in reducing human error by following precise assembly guidelines.

Throughout manufacturing, multiple checkpoints are established where products are thoroughly examined by quality control teams. This process helps in adhering to international standards, ensuring that the performance matches the specifications. These strict internal practices help minimize defects, maintaining uniform brightness, color accuracy, and reliability across batches.

Additionally, manufacturers may adhere to standards like ISO 9001 and ISO 14001, which focus on quality management and environmental management, respectively. These certifications ensure that the manufacturing process is efficient and sustainable, contributing to consistent product quality.

What’s the Role of the Driver in LED Lights?

The driver is basically the heart of an LED fixture, managing power and electrical flow. It converts electricity from your source into suitable voltage and current for LED chips. High-quality drivers, sourced from trusted names like Philips or Meanwell, ensure LED fixtures remain stable, flicker-free, effective, and safe. Poor-quality drivers cause fluctuations in power, leading to flickering lights, reduced lifespans, or complete failure. Provided that premium drivers are utilized, businesses and consumers enjoy safer, more reliable, and longer-lasting LED fixtures, resulting in greater customer satisfaction and less replacement effort.

LED Flood Light with Meanwell Driver

How Do I Choose a Trustworthy LED Lighting Supplier?

Selecting trustworthy suppliers involves evaluation on various factors. Reputable companies have transparent production processes and clearly identified components. Look for proven manufacturers that demonstrate detailed knowledge of thermal management, sustainability, and international testing standards. Reliable suppliers willingly share product datasheets, testing certificates, and client testimonials. Established manufacturers like Logos Lighting maintain effective communication channels, flexible customization capabilities, and efficient delivery schedules, making your sourcing easy and dependable.

Choosing LED lighting is always smarter when you understand how LEDs are made and the quality processes behind them. Knowing the steps involved—such as LED chip fabrication, choosing quality materials like premium drivers and aluminum heat sinks, attention to thermal management, adherence to standards like EMC, LVD, UL, LM-79 and LM-80 testing, and commitment to sustainable manufacturing—will help you confidently select lighting fixtures that are bright, long-lasting, and reliable. If you have any questions or need quality LED lighting solutions, just feel free to contact us directly. Our lighting experts are ready to help.

Request A Free Quote Now!

Send us a message if you have any questions or request a quote. We will get back to you ASAP!

Leave a Reply

Your email is safe with us.