Ever wasted hours researching lighting, feeling overwhelmed by confusing terms and endless options? Poor lighting hurts workplace efficiency, increases energy bills, and even causes accidents. LED high bay lighting is your solution. I’ll show you how.

If you’re looking for simple, energy-efficient lighting solutions for your warehouse, factory, gym, or large workspace, LED high bay fixtures are a smart choice. These lights use less electricity, last longer, and produce brighter illumination than traditional lighting. Key advantages include significantly reduced energy bills, lower maintenance costs, clearer visibility, and safer working environments. Common types are UFO high bay lights and linear high bays, suitable for various ceiling heights. Installation is straightforward, and adding controls like high bay occupancy sensors further boosts energy-saving potential. Let’s explore how choosing the right high bay lights can improve efficiency and save money.

I’m here to guide you step-by-step, making LED high bay lighting easy to understand and implement, so please stick with me!

Table of Contents

What Exactly Are LED High Bay Fixtures?

Simply put, LED high bay fixtures are heavy-duty lighting solutions built for large indoor areas with high ceilings. You’ll find them used in places like warehouses, manufacturing plants, gymnasiums, supermarkets, and big workshops. These spaces often have ceilings that go beyond 5 meters in height, where regular lights just don’t deliver enough brightness. That’s where high bay LEDs come in—they push out powerful light that covers large areas efficiently.

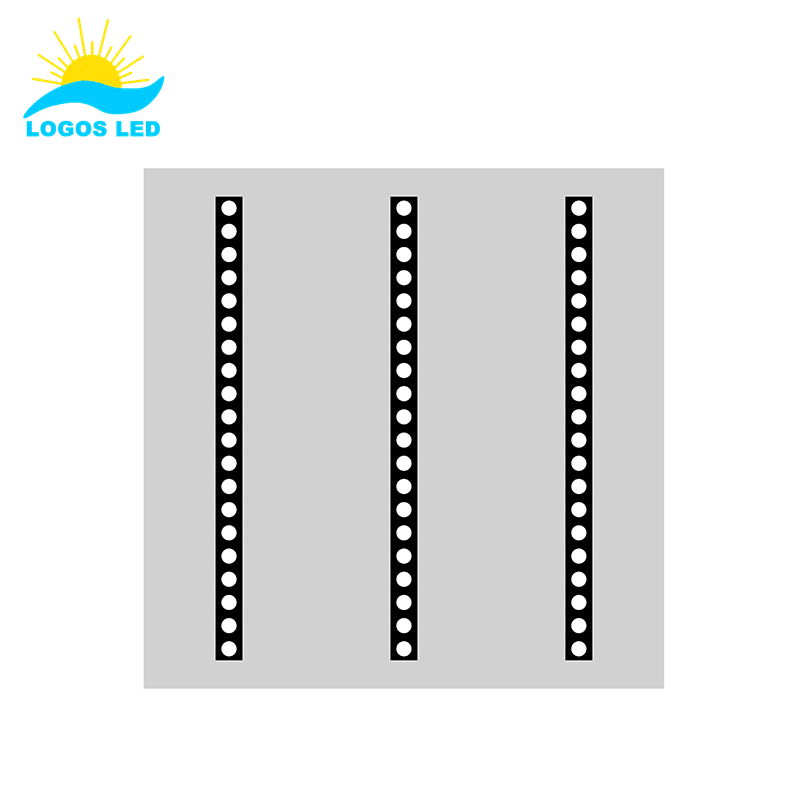

There are two main types of high bay lights you’ll see. First, UFO high bay lights, which are round and compact—great for open spaces that need uniform brightness. Then there are linear high bays, shaped more like fluorescent tubes. These work better in areas with long aisles or rows, like logistics centers or assembly lines. Both types are known for their high lumen output, long lifespan, and low energy consumption, making them a smart upgrade over traditional metal halide or fluorescent lights.

Major Advantages of Switching to Industrial LED Lighting

Switching to industrial LED lighting is one of those rare decisions that brings immediate and long-term rewards. I’ve seen how businesses watch their energy bills shrink almost overnight after making the switch from traditional lighting to LEDs. It’s impressive how LEDs consume significantly less electricity while delivering equal, if not better, brightness. Maintenance hassles? Say goodbye! High-quality LED high bay lights can keep glowing brightly for up to 50,000 hours. This means the days of frequently replacing bulbs are over.

Moreover, these LED lights do wonders for the workspace, creating a clearer and more vibrant environment. This increase in brightness not only helps in enhancing the aesthetic appeal but also elevates employee satisfaction and safety levels. I’ve come to realize that making an initial investment in LED lighting isn’t just smart; it’s a commitment to years of savings and reliability. You get more than just lights; you get peace of mind and a solid return on your investment.

Choosing the Correct LED Lumens and Wattage

Understanding lumens and wattage is crucial for selecting the right LED high bay lights. Lumens, which measure brightness, are essential for determining how well-lit your space will be. On the other hand, wattage indicates the amount of energy your light consumes. A higher lumen count means a brighter light, while lower wattage signifies less energy use, translating to cost savings. For instance, traditional metal halide lights using about 250 watts can be efficiently replaced by LEDs that require just 100 watts, offering the same level of illumination.

When selecting LED lights, focusing on lumens rather than wattage ensures you achieve the ideal brightness for your needs. It’s crucial to always check the lumen value to match your specific lighting requirements accurately and to maximize energy efficiency. This approach not only improves lighting quality but also significantly reduces energy costs, making the switch to LEDs a wise investment.

UFO High Bay Lights or Linear High Bays: Which Is Better?

When deciding between UFO high bay lights and linear high bay fixtures, it’s essential to consider the shape of your workspace and the height of the ceiling. UFO high bay lights are designed to emit focused, intense brightness, making them ideal for vast, open spaces such as warehouses and gymnasiums. Their design ensures that powerful illumination is directed straight down, providing excellent lighting for areas that require focused light from above.

In contrast, linear high bay fixtures are perfect for distributing light evenly in narrower and longer spaces, like aisles, corridors, and assembly lines. Their elongated structure allows for a broader spread of light, ensuring consistent and harmonious coverage throughout these areas. From my experience in various projects, linear models are best suited for spaces where uniform lighting is crucial to avoid dark spots. On the other hand, UFO lights shine in wider, open floor spaces, delivering concentrated brightness precisely where it’s needed. Each type has its unique advantages, tailored to fit the specific needs of different environments.

Installation Tips for High Bay Lighting

Installing high bay lighting might seem daunting at first, but it’s quite straightforward once you grasp the essentials. Always start by turning off the electricity to ensure safety during installation. It’s crucial to place the fixtures uniformly to prevent shadows and dark spots—this means spacing the lights evenly for balanced lighting throughout the area.

The height at which you install the lights plays a significant role in their effectiveness. Generally, positioning them 5 to 6 meters high provides optimal coverage for most spaces. Using adjustable mounting hardware can offer flexibility, allowing you to adjust the height as necessary to suit specific needs.

If you’re unsure about any step in the process, don’t hesitate to seek professional assistance. Proper installation is key to ensuring that your lighting system operates at maximum efficiency, delivering the best possible performance and illumination.

low bay vs high bay light

Do High Bay Occupancy Sensors Really Help?

Incorporating occupancy sensors into your high bay lighting setup is a fantastic way to enhance energy conservation. These sensors automatically activate lights when they detect movement below and turn them off when the area is unoccupied. I’ve observed firsthand how businesses can significantly cut down on monthly energy expenses by implementing these sensors, particularly in areas or aisles that aren’t frequently used.

Occupancy sensors can reduce energy usage by up to 30% more compared to standard LED fixtures alone. This makes the initial investment in these sensors highly worthwhile. It’s a straightforward yet powerful strategy to amplify the cost savings that already come with LED warehouse lighting. By ensuring lights are only on when necessary, businesses can enjoy greater efficiency and lower energy bills.

Cost Savings with LED Warehouse Lighting

LED high bays immediately reduce energy bills; that’s a simple fact I’ve observed across industries. Typically, businesses see between 50-70% lower electricity costs after switching from traditional lights to LEDs. Maintenance expenses also become much lower since LEDs rarely need replacements. The combined savings are substantial when measured month by month, quickly covering the startup cost and turning into pure profit afterward. In short, LED warehouse lighting pays for itself many times over through reduced bills and minimal maintenance.

Is More Expensive Always Better Quality?

Price matters, but expensive doesn’t always equal better quality. Brands that use high-quality LED chips—Lumileds or Osram—and reliable drivers from Philips or Meanwell produce more durable, brighter lighting fixtures. Superior materials help your high bay lights last years without problems. While low-priced options might seem appealing initially, poor-quality lighting usually means higher costs later from repairs or replacements. Aim for reasonable pricing from trusted suppliers to ensure your investment provides long-term value.

How to Choose A Good Supplier for LED High Bay Lights

Selecting the right supplier is crucial as it impacts both the quality of products and overall cost-effectiveness. When I’m searching for suppliers, I prioritize those with extensive experience in industrial LED lighting and who can communicate promptly and clearly. A reliable supplier, like Logos Lighting, provides transparent information, tailored product solutions, and efficient shipping, which helps streamline the supply chain process and minimize frustrations.

To find such suppliers, I recommend attending trade shows, conducting thorough Google searches, and seeking recommendations from industry professionals. It’s also vital to read customer reviews to verify that the supplier’s reputation and dedication align perfectly with your expectations and requirements. Don’t underestimate the power of due diligence in ensuring you partner with the right supplier for your needs.

Conclusion

Switching to LED high bay lighting can be straightforward and stress-free. Start by choosing fixtures that suit your specific space. Once installed correctly, you’ll quickly begin to experience numerous benefits: brighter and safer work environments, substantial cost savings through enhanced energy efficiency, reduced maintenance needs, and a decreased environmental impact.

Taking this step puts you in control of transforming your workspace for the better. If you need expert assistance in selecting or setting up your LED high bay lights, don’t hesitate to reach out to me directly at [email protected]. We’re eager to support your journey to a more efficient and effective lighting solution!

Request A Free Quote Now!

Send us a message if you have any questions or request a quote. We will get back to you ASAP!