Picking the wrong LED tube light can lead to flickering, wasted energy, and even safety risks. And rework? That costs you time and money. Here’s how to get it right.

LED tube lights are energy-efficient replacements for traditional fluorescent tubes. They come in different sizes (T5, T8, T12) and wiring types (Type A, B, A+B, C). Choosing the right LED tube depends on your fixture, ballast compatibility, brightness needs, and installation method. With the right info, you can pick a tube that fits perfectly, saves power, and lasts for years—no rewiring headaches, no costly returns.

Keep reading so you don’t waste another dollar on the wrong lighting.

Table of Contents

What Is LED Tube Lights?

LED tube lights are energy-efficient replacements for traditional fluorescent tubes. Instead of using gas and mercury to create light, they rely on light-emitting diodes (LEDs) to produce a brighter, cleaner, and more efficient light source.

These tube lights are designed in standard lengths like 2-foot, 4-foot, and 8-foot, making them a direct fit for existing fixtures in offices, warehouses, schools, hospitals, and retail stores. They’re ideal for both retrofitting older systems and installing in new setups.

Compared to fluorescent tubes, LED tubes:

– Use up to 60% less energy

– Last significantly longer—often over 50,000 hours

– Produce less heat

– Turn on instantly with no flicker or buzzing

– Are free of mercury and other toxic materials

What Does T5, T8, T12 Mean in Lighting?

T5, T8, and T12 are labels that refer to the diameter of a tube light. The number after the “T” stands for how many eighths of an inch wide the tube is:

- T5 = 5/8 inch

- T8 = 1 inch (8/8)

- T12 = 1.5 inches (12/8)

So, a T8 tube is thicker than a T5 but slimmer than a T12. This measurement matters because it affects what fixtures the tube will fit into. If you’re replacing old fluorescent tubes with LED versions, make sure to match the tube size to the existing fixture.

Where Are They Used?

- T8: The most common size today, often found in offices, schools, shops, and warehouses.

- T5: Used in newer, energy-efficient systems. These are slim and usually found in commercial buildings and high-performance lighting setups.

- T12: These are the oldest and thickest type. You’ll typically see them in older buildings or installations that haven’t been upgraded yet.

If you’re planning a retrofit, always check your existing tube’s size and socket type. That way, you’ll know which LED replacement will fit properly without rewiring or changing the fixture.

What Is the Difference Between Type A, Type B, Type A+B, and Type C LED Tubes?

If you’re upgrading from fluorescent tubes to LED, choosing the right type of LED tube is key—and this is where most people get tripped up. The type you choose determines how the tube is powered and installed. Here’s a simple breakdown to help you avoid confusion and wiring errors:

Type A (Plug and Play)

This is the easiest and fastest to install. Type A tubes work directly with your existing fluorescent ballast. You just remove the old tube and plug in the new LED. No rewiring is needed. However, the LED’s performance depends on the condition of the old ballast. If the ballast fails, the tube stops working.

Type B (Ballast Bypass)

With Type B tubes, you remove the ballast entirely and wire the power directly to the tube’s ends. This setup eliminates future ballast failures and improves energy efficiency. It takes a bit more time to install, and it’s important to follow safety guidelines—because you’re wiring directly to line voltage.

Type A+B (Hybrid)

Hybrid tubes offer flexibility. You can start by plugging them into a fixture with a working ballast (Type A mode). Later, if the ballast fails, you can bypass it and rewire the fixture (Type B mode). It’s a good option if you want an easy install now with the option for long-term reliability later.

Type C (External Driver)

This type uses a separate LED driver—just like LED panels or troffers. The external driver provides stable, high-quality power and allows for better control options like dimming. Type C is best for large projects where long-term performance, advanced control, or compatibility with smart systems is important.

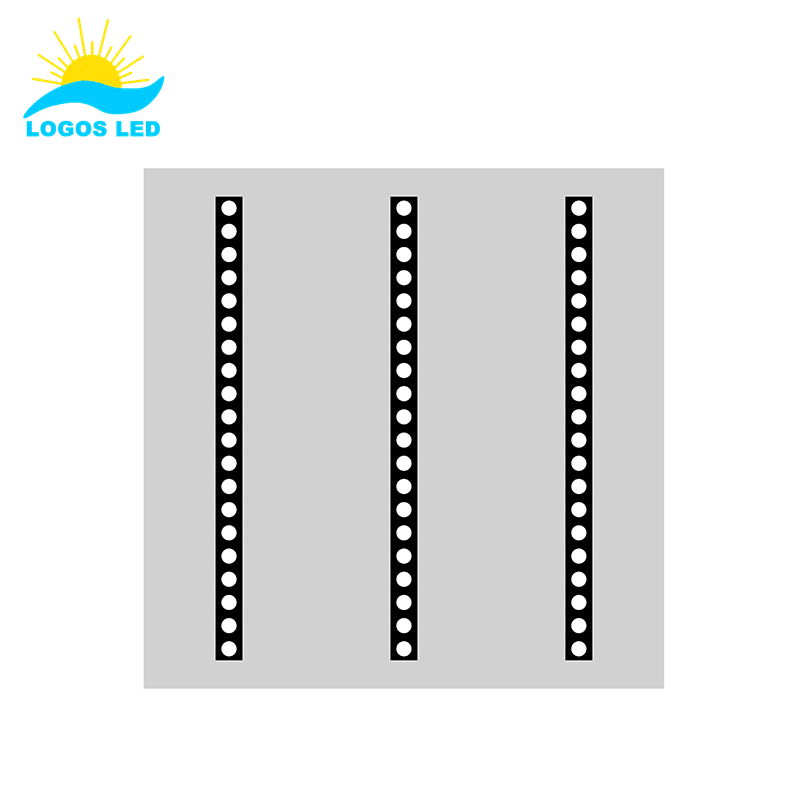

Types of LED Tubes

Which One Should You Choose?

- Want the fastest install with no rewiring? Go with Type A.

- Want the most reliable long-term setup? Choose Type B or C.

- Want flexibility to upgrade later? Type A+B is your best bet.

What Are the Different LED Tube Lights Base Types?

LED tube lights come in several base types to match the sockets found in existing fluorescent fixtures. The base type determines how the tube connects to the fixture, so it’s important to choose the right one for your setup. Here are the most common LED tube light base types:

G13 Base

This is the most common base for T8 and T12 tubes. It has two pins spaced 13 millimeters apart. G13 bases are typically used in offices, warehouses, and commercial settings. If you’re replacing a 4-foot fluorescent tube, this is likely the one you need.

G5 Base

Used for T5 tubes, the G5 base has pins that are 5 millimeters apart. These tubes are thinner and often found in newer, high-efficiency fixtures. They’re common in schools, retail stores, and display cases.

FA8 Base

This is a single-pin base found on some 8-foot fluorescent tubes. It’s used mainly in industrial and commercial facilities where long, high-output tubes are needed. FA8 LED tubes are typically Type B, requiring ballast bypass.

R17D Base (Recessed Double Contact)

Also used for 8-foot tubes, the R17D base features recessed double contacts. It’s common in older high-output fixtures. Make sure to confirm compatibility, as not all 8-foot tubes use the same base.

2G11 Base

This is a 4-pin base used in compact linear fluorescent fixtures. It’s less common but can still be found in specialty or architectural lighting applications.

2G7 or G24 Bases

These are used for PL-style (plug-in) LED replacements for compact fluorescent lamps. They are often found in recessed can lights, wall sconces, and task lighting.

When retrofitting, always double-check the tube length, diameter (T5, T8, T12), and the base type to ensure the new LED tube will fit and function correctly in your existing fixture.

How to Choose a LED Tube Light

When selecting LED tube lights, especially for commercial or large-scale projects, getting the right match is crucial for safety, performance, and long-term savings. Here’s how to approach the decision:

1. Know Your Tube Size

Identify whether you’re replacing a T5, T8, or T12 tube. These labels refer to the tube’s diameter. If you’re unsure, measure the tube’s width or check the label.

2. Check the Ballast

If you prefer a quick installation with no rewiring, choose Type A (plug-and-play). If your ballast is old or unreliable, go with Type B (ballast bypass) or Type A+B (hybrid) for flexibility between both methods.

3. Look at Wattage and Lumens

Wattage shows power usage, while lumens show brightness. A 40-watt LED tube should offer over 4800 lumens. Match the brightness to your application—higher lumens for warehouses, moderate for offices or classrooms.

4. Pick a Color Temperature

Choose based on how you want the space to feel:

– 3000K (warm white): Cozy and relaxed, good for homes.

– 4000K–5000K (neutral white): Balanced and clean, good for offices and schools.

– 6000K+ (daylight white): Bright and clear, ideal for industrial spaces.

5. Check Certifications

Make sure the tubes meet safety and performance standards such as UL, DLC, CE, or RoHS depending on your region.

6. Review the LED Tube Light Wiring Diagram

Understanding the wiring ensures proper installation and avoids errors. Always check the diagram provided with the product. If it’s unclear, ask for clarification before installation.

These steps help ensure that your LED tube lights meet your performance goals while staying safe and efficient.

FAQs About LED Tube Lights

Can I directly replace fluorescent tubes with LED?

Yes, but only if you’re using Type A LED tubes that are specifically designed to work with your existing fluorescent ballast. These are plug-and-play options. However, not all LED tubes are the same—Type B and Type C require rewiring. Always check the LED tube type and make sure it matches your fixture and ballast before installation.

What happens if you put a T8 bulb in a T12 fixture?

While a T8 bulb might physically fit into a T12 fixture, it likely won’t work correctly. That’s because T12 fixtures typically use magnetic ballasts, which are not compatible with most T8 LEDs. You could experience flickering, poor light output, or no light at all. In some cases, using the wrong combination may damage the LED tube.

Do I need to remove ballast for LED lights?

Only if you’re installing Type B or Type C LED tubes. These types require bypassing or removing the ballast and wiring the power directly to the tube. This setup eliminates future ballast failures and slightly improves energy efficiency. Just be sure the rewiring is done safely—consider hiring a licensed electrician if you’re unsure.

Is it worth replacing fluorescent tubes with LED?

Yes, it’s definitely worth it. LED tubes use up to 60% less energy compared to fluorescent tubes. They also last much longer—typically over 50,000 hours—reduce maintenance needs, and provide better light quality. They turn on instantly, don’t flicker, and don’t contain mercury. In most cases, the energy savings alone pay back the cost of the upgrade within a year.

Summary

Choosing the right LED tube light isn’t hard when you know what to look for—size, ballast compatibility, wiring type, wattage, and certifications. Get it right the first time, and you’ll enjoy years of maintenance-free, energy-saving lighting.

Need help choosing the perfect LED tube for your project? Contact us directly and we’ll guide you every step of the way!

Request A Free Quote Now!

Send us a message if you have any questions or request a quote. We will get back to you ASAP!