Struggling with flickering and high energy costs from your fluorescent shop lights? Outdated lights can drain your wallet and leave your workspace poorly lit. Switching to LED solves these problems, providing brighter light and lower energy consumption. Here’s how to do it right.

Converting fluorescent shop lights to LED is a cost-effective way to upgrade your lighting. You can retrofit your existing fixtures with LED tubes or install brand-new LED shop light fixtures. Retrofitting allows you to use the same fixtures by bypassing the ballast, while installing new LED fixtures offers more efficient and modern lighting. Both options drastically reduce energy consumption and maintenance costs. LED tubes last longer and provide more consistent brightness, making them a smart investment for any workspace.

Keep reading to learn the step-by-step process for making the switch.

Table of Contents

What is the Difference Between LED and Fluorescent Light?

When comparing LED and fluorescent lights, the differences are clear in terms of technology, energy efficiency, lifespan, durability, and light quality.

Technology

- Fluorescent Lights: Operate by passing electricity through mercury vapor, which then emits ultraviolet (UV) light. This UV light hits a phosphor coating inside the tube, creating visible light.

- LED Lights: Use light-emitting diodes (LEDs) made of semiconductors. When current passes through the LED chip, it emits light through electroluminescence, which is far more efficient than gas-based lighting.

LED technology is solid-state, meaning there are no moving parts or fragile components, while fluorescent lights rely on gas and glass, making them more prone to damage.

Energy Consumption

- Fluorescent Lights: Typically consume 30–40 watts per tube. They also lose energy as heat during operation.

- LED Lights: Consume 15–20 watts for the same or even greater brightness, reducing energy usage by up to 50% compared to fluorescent lights.

This efficiency results in lower electricity costs, especially in large installations like offices, warehouses, and industrial spaces.

Lifespan

- Fluorescent Lights: Last around 10,000 to 15,000 hours under optimal conditions.

- LED Lights: Last up to 50,000 hours or more, which is approximately 5 times longer than fluorescents.

The longer lifespan of LEDs means fewer replacements and reduced maintenance costs, making them a cost-effective solution over time.

Durability

- Fluorescent Lights: Contain glass and mercury, making them fragile and hazardous if broken. They are also sensitive to cold temperatures and vibrations.

- LED Lights: Built with solid-state technology, they are far more durable. LEDs handle vibrations, temperature changes, and environmental factors much better, making them ideal for industrial and outdoor applications.

LEDs do not contain mercury, which is both safer and more environmentally friendly.

Light Quality

- Fluorescent Lights: Tend to flicker and produce uneven light, especially when ballasts begin to wear out. The light quality also degrades over time, becoming dimmer and less reliable.

- LED Lights: Deliver instant, flicker-free light with a higher Color Rendering Index (CRI), ensuring colors appear more natural and vivid.

LEDs are also fully dimmable, while most fluorescent lights require special ballasts to achieve dimming.

Environmental Impact

- Fluorescent Lights: Contain mercury, which is hazardous and requires careful disposal. They also consume more energy, increasing their carbon footprint.

- LED Lights: Are mercury-free and fully recyclable. Their lower energy consumption also reduces greenhouse gas emissions, contributing to a greener environment.

Cost Considerations

- Fluorescent Lights: Have a lower upfront cost but higher maintenance and energy expenses over time.

- LED Lights: Higher initial cost but far cheaper in the long run due to energy savings and reduced maintenance.

Summary Comparison

| Feature | Fluorescent Light | LED Light |

|---|---|---|

| Technology | Gas and electricity with UV emission | Semiconductor-based (solid-state) |

| Energy Use | 30–40 watts per tube | 15–20 watts per tube |

| Lifespan | 10,000–15,000 hours | Up to 50,000 hours |

| Durability | Fragile, sensitive to temperature | Shock-resistant, durable |

| Light Quality | Flickers, degrades over time | Bright, flicker-free, instant on |

| Environmental | Contains mercury, hazardous | Mercury-free, eco-friendly |

| Cost Over Time | Higher energy and maintenance costs | Lower energy and maintenance costs |

LED lights are superior in almost every aspect—efficiency, durability, lifespan, and environmental impact. While the initial cost is slightly higher, the long-term savings make them the clear choice for both residential and commercial applications.

LED Tube Light Applications

Can You Replace Fluorescent Shop Lights with LED?

Yes, you can replace fluorescent shop lights with LED. You have two main options:

- Retrofit LED Tubes: These allow you to use your existing fluorescent fixture by bypassing the ballast. They fit right into the current sockets, making it a smooth transition.

-

New LED Shop Lights: You can replace the entire fixture with a new LED shop light fixture. This is ideal if your old fixture is outdated or damaged.

Both methods are cost-effective and energy-saving, but retrofitting is typically faster and easier.

How to Convert Fluorescent Shop Lights to LED?

There are two primary ways to convert your fluorescent shop lights to LED: Retrofitting and Installing New Fixtures.

Retrofitting Your Fluorescent Shop Lights with LED

Here’s how you can do it step by step:

- Turn Off the Power: Safety first. Make sure the power is completely off.

- Remove the Fluorescent Tubes: Carefully take out the old fluorescent tubes.

- Open the Fixture and Remove the Ballast: If you’re using ballast-bypass LED tubes, you need to remove or bypass the ballast.

- Rewire the Fixture: Connect the live and neutral wires directly to the sockets. This allows current to flow directly to the LED tubes.

- Install the LED Tubes: Place the LED tubes into the sockets.

- Power On and Test: Switch the power back on and test your new LED lights.

Installing New LED Shop Light Fixtures

If you want a complete upgrade, consider installing new LED shop lights. Here’s how:

- Turn Off the Power: Safety is critical.

- Remove the Old Fixture: Take out the entire fluorescent fixture.

- Mount the New LED Fixture: Install the LED fixture where the old one was.

- Wire the New Fixture: Follow the wiring instructions for your new LED shop light.

- Power On and Test: Restore the power and test your lights.

This option is perfect for those wanting a fresh, modern look.

Things to Consider Before Converting Fluorescent Lights to LED

Upgrading from fluorescent lights to LED is a smart move for energy savings and better light quality. However, there are a few important factors to consider to ensure a smooth transition.

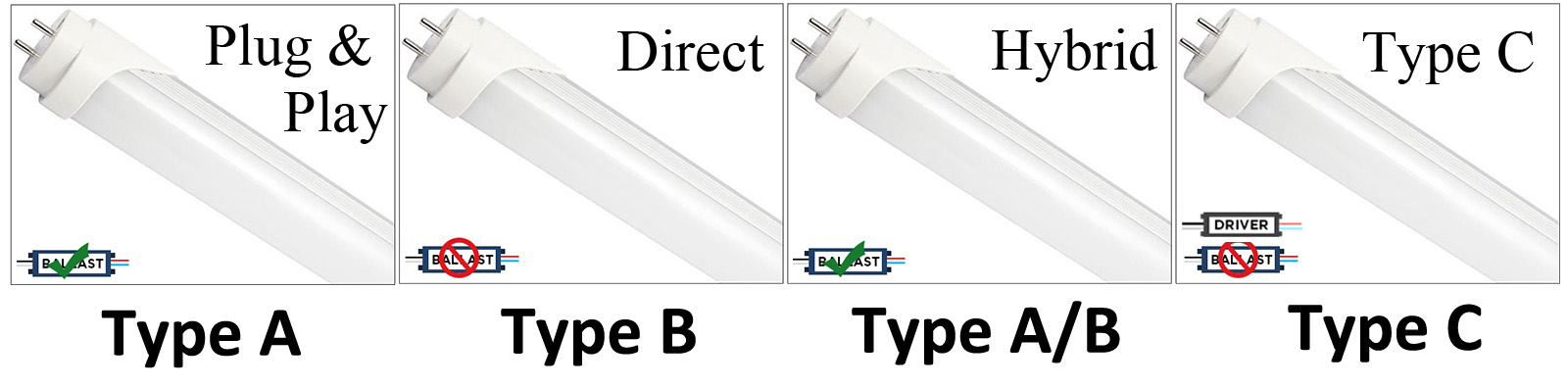

1. Type of LED Tubes

There are different types of LED tubes available, and choosing the right one is crucial for compatibility and performance:

- Type A (Plug-and-Play): These are compatible with existing electronic ballasts. Simply remove the fluorescent tube and insert the LED tube. No rewiring is required.

- Type B (Ballast Bypass): These require bypassing or removing the existing ballast. They are wired directly to the main power supply. This type is more efficient since there’s no energy loss through the ballast, but installation is more complex.

- Type A+B (Hybrid): These can work with the existing ballast but can also be wired directly if the ballast fails. This provides flexibility during installation.

- Type C (External Driver): These require an external LED driver for power regulation. They are ideal for more controlled and efficient lighting.

Understanding the differences will help you select the best option for your current setup.

2. Wiring Requirements

Not all LED replacements are plug-and-play. Type B and Type C require some rewiring. Here’s what to consider:

– Type A: No rewiring needed—simply replace the old tube.

– Type B: Requires removing or bypassing the ballast and direct wiring to the power source.

– Type C: Needs an external driver and rewiring for proper installation.

If you are not familiar with electrical work, it’s recommended to consult a professional to ensure safety and compliance with electrical codes.

3. Power Supply Compatibility

Check if your current fixture is compatible with LED tubes. Here’s what you need to verify:

– Voltage Rating: Ensure the fixture’s voltage matches the LED tube’s requirements.

– Ballast Compatibility: If you are using Type A LED tubes, make sure the ballast is electronic and not magnetic. Older magnetic ballasts are not compatible.

– Condition of the Fixture: Inspect the fixture for any signs of wear or damage before installation.

If your fixture is old or damaged, it may be a good time to replace it entirely with a modern LED-ready fixture.

4. Ballast Type

If you plan to use Type A or hybrid Type A+B LED tubes, the existing ballast must be compatible:

– Electronic Ballasts: Most LED Type A tubes are compatible.

– Magnetic Ballasts: Generally not compatible; you may need to bypass or replace the ballast.

– Rapid Start and Programmed Start: Check the LED specifications to confirm compatibility.

If you are unsure of your ballast type, it is often marked on the ballast label, or you can consult the fixture’s documentation.

5. Cost of Installation

Switching to LED involves some upfront costs:

– LED Tubes: Generally more expensive than fluorescent tubes, but they last longer and consume less energy.

– Installation Costs: If rewiring or ballast replacement is required, you may need to hire an electrician, adding to the cost.

– New Fixtures (Optional): If your existing fixtures are old, you might consider upgrading them during the conversion.

6. Light Output and Color Temperature

When switching to LED, consider the light output (lumens) and color temperature (Kelvin):

– Lumens: Ensure the LED tube provides the same or greater brightness as your fluorescent tube.

– Color Temperature: Choose the right color for your space:

– 3000K (Warm White): Good for residential and cozy spaces.

– 4000K (Neutral White): Ideal for offices and workspaces.

– 5000K (Daylight White): Perfect for warehouses and areas requiring clear visibility.

7. Disposal of Fluorescent Tubes

Fluorescent tubes contain mercury, making proper disposal important. Follow local regulations for hazardous waste disposal to avoid environmental contamination.

Summary Checklist

| Consideration | Key Points |

|---|---|

| LED Tube Type | Choose between Type A, Type B, Hybrid, or Type C |

| Wiring Requirements | Plug-and-play vs. ballast bypass rewiring |

| Power Compatibility | Match voltage and ballast type |

| Ballast Type | Verify electronic vs. magnetic compatibility |

| Cost of Installation | Factor in electrician costs if rewiring is needed |

| Light Output & Color | Select appropriate lumens and color temperature |

| Disposal Requirements | Fluorescent tubes require safe disposal |

Switching from fluorescent to LED is a powerful upgrade that brings better efficiency, longer lifespan, and superior light quality. By understanding these considerations, you can make the switch smoothly and effectively.

LED tube light Application in supermarket

Can You Put an LED Tube in a Fluorescent Fixture?

Yes, you can install an LED tube in a fluorescent fixture, but it depends on the type of LED tube:

- Type A (Plug and Play): Works directly with your existing ballast. Simply swap the fluorescent tube for an LED tube.

- Type B (Ballast Bypass): Requires you to bypass or remove the ballast.

- Type C (External Driver): Uses an external LED driver for better efficiency and dimming options.

The easiest option is Type A, but for better long-term savings, Type B is recommended as it eliminates ballast maintenance.

Do I Need to Remove Ballast for LED Lights?

That depends on the type of LED tube you choose:

- Plug and Play (Type A): No ballast removal required.

- Ballast Bypass (Type B): Yes, you need to remove or bypass the ballast.

- Hybrid (Type AB): Works with or without the ballast.

- External Driver (Type C): Requires a separate driver instead of the ballast.

If you’re looking for long-term savings, bypassing the ballast is recommended. It reduces energy consumption and eliminates maintenance costs.

Types of LED Tubes

Conclusion

Converting fluorescent shop lights to LED is a smart investment. You get brighter light, save on energy, and reduce maintenance costs. You can retrofit your current fixture or upgrade entirely to new LED shop lights. Both options improve lighting quality and cut down on your energy bill.

If you’re ready to make the switch to LED for your shop lights, contact us at Logos Lighting today. We’re here to help you get it right the first time!

Request A Free Quote Now!

Send us a message if you have any questions or request a quote. We will get back to you ASAP!