Table of Contents

Introduction

Step into a well-lit workspace that not only fosters productivity but also exudes a modern and industrial aesthetic. Whether you’re setting up a garage, warehouse, or office, the right lighting supplies can transform any space. In this ultimate guide to industrial lighting supplies, we’ll explore everything you need to know to illuminate your workspace effectively. From choosing the right types of fixtures to understanding the different lighting technologies available, we’ve got you covered.

Our expert team has handpicked the most reliable and energy-efficient options available in the market, so you can make an informed decision. We understand that every workspace has unique requirements, and that’s why we’ll discuss the various factors to consider before purchasing your lighting supplies. By the end of this guide, you’ll have the knowledge and confidence to create a well-lit environment that enhances productivity and creates a positive working atmosphere.

Discover the best industrial lighting supplies and unlock the potential of your workspace. Don’t settle for dim and dull, let’s brighten up your world together.

Importance of Proper Lighting in the Workspace

Proper lighting in the workspace is crucial for several reasons. Firstly, it directly affects the productivity and well-being of employees. Inadequate lighting can lead to eye strain, fatigue, and a decrease in focus, resulting in decreased efficiency. On the other hand, well-designed lighting can boost mood and energy levels, creating a positive and vibrant atmosphere that encourages productivity.

Secondly, proper lighting enhances safety in the workspace. Insufficient lighting can create hazards and increase the risk of accidents. Adequate illumination ensures that employees can navigate the space safely, identify potential dangers, and carry out their tasks effectively.

Lastly, lighting plays a significant role in the overall aesthetics of the workspace. Industrial lighting supplies not only serve a functional purpose but can also contribute to the overall design and atmosphere of the environment. With the right lighting fixtures and technologies, you can create a visually appealing and modern workspace that leaves a lasting impression on clients and employees alike.

When it comes to industrial lighting supplies, there are various options available to suit different needs and preferences. Let’s explore some of the most popular types of fixtures and technologies in the next section.

Types of Industrial Lighting Supplies

- High Bay Lighting: High bay lighting fixtures are designed for spaces with high ceilings, such as warehouses and manufacturing facilities. These fixtures provide bright and uniform illumination over a large area. They typically use metal halide, high-pressure sodium, or LED technology.

- Floodlights: Floodlights are versatile lighting fixtures that are commonly used outdoors or in large open spaces. They provide a wide beam of light, ideal for illuminating parking lots, sports fields, and construction sites. Floodlights can be mounted on poles, walls, or the ground, depending on the specific requirements.

- Task Lighting: Task lighting focuses on providing localized illumination for specific tasks or work areas. It is commonly used in offices, workshops, and laboratories. Task lighting fixtures can include desk lamps, under-cabinet lights, and adjustable spotlights. These fixtures ensure that the area where work is being performed is adequately illuminated, reducing eye strain and improving productivity.

- Linear Fixtures: Linear fixtures, also known as strip lights or linear lights, are long and narrow lighting fixtures that provide continuous and even illumination. They are often used in retail spaces, offices, and commercial buildings. Linear fixtures can be recessed into the ceiling or surface-mounted, offering flexibility in installation.

- Emergency Lighting: Emergency lighting is a crucial component of any workspace, especially in areas where sudden power outages or emergencies may occur. These fixtures are designed to provide sufficient illumination in the event of an emergency, ensuring the safe evacuation of employees. Emergency lighting can include exit signs, emergency light units, and backup power systems.

Now that we’ve covered the different types of industrial lighting supplies, let’s delve into the factors you should consider when choosing the right fixtures for your workspace.

Factors to Consider When Choosing Industrial Lighting Supplies

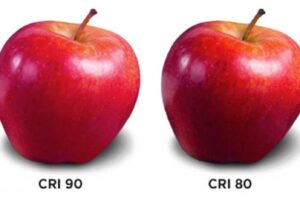

- Brightness and Illumination Levels: The level of brightness required in your workspace depends on the nature of the tasks being performed. Consider the specific lighting requirements for each area and choose fixtures that provide adequate illumination. Pay attention to the color temperature and color rendering index (CRI) of the bulbs or LEDs used in the fixtures, as these factors affect the quality of light produced.

- Energy Efficiency: Energy-efficient lighting not only helps reduce electricity costs but also has a positive impact on the environment. Look for lighting supplies that are labeled as energy-efficient or have high efficacy ratings. LED lighting, in particular, is known for its energy efficiency and long lifespan, making it a popular choice for many workspaces.

- Durability and Maintenance: In industrial settings, lighting fixtures may be exposed to harsh conditions such as dust, moisture, and vibrations. It is essential to choose fixtures that are durable and can withstand these challenging environments. Consider the maintenance requirements of the fixtures as well, as regular upkeep can ensure their optimal performance and longevity.

- Lighting Control Options: Having control over the lighting in your workspace allows you to customize the illumination levels based on specific needs. Look for fixtures that offer dimming capabilities or integrate with smart lighting systems. This flexibility allows you to create different lighting scenes for various tasks or adjust the lighting based on natural light levels.

- Cost and Budget: Consider your budget when selecting industrial lighting supplies. While it may be tempting to opt for cheaper options, keep in mind that quality and performance are essential factors. Investing in reliable and high-quality lighting supplies may save you money in the long run through energy savings and reduced maintenance costs.

By considering these factors, you can make an informed decision when choosing the right industrial lighting supplies for your workspace. In the next section, we’ll explore some popular industrial lighting brands and manufacturers known for their quality and reliability.

Popular Industrial Lighting Brands and Manufacturers

When it comes to industrial lighting supplies, choosing reputable brands and manufacturers can give you peace of mind regarding quality and performance. Here are some popular brands known for their reliable and innovative lighting solutions:

- Philips: Philips is a well-established brand in the lighting industry, offering a wide range of industrial lighting solutions. Their product lineup includes LED fixtures, high bay lights, floodlights, and emergency lighting. Philips is known for their commitment to energy efficiency and sustainability.

- Osram: Osram is a global lighting company that offers a comprehensive range of industrial lighting solutions. Their product lineup includes LED fixtures, fluorescent lamps, and control systems. Osram is known for their focus on energy efficiency, durability, and lighting performance.

- Eaton: Eaton is a multinational power management company that provides a wide range of industrial lighting solutions. Their product range includes LED fixtures, emergency lighting, and outdoor lighting. Eaton’s lighting solutions are known for their reliability, energy efficiency, and innovative designs.

- Zumtobel: Zumtobel is a prominent name in lighting, known for their tailored solutions that merge aesthetic appeal with unctionality.

- Logos Lighting: Offering a blend of contemporary designs and robust performance, Logos Lighting is a notable brand in the architectural and industrial sectors.

- Hubbell Lighting: Renowned for its engineering excellence, Hubbell Lighting provides a comprehensive range of products that ensure reliability and efficiency.

- TCP Lighting: TCP Lighting stands out for its cost-effective and energy-efficient lighting solutions that do not compromise on quality or performance.

- Dialight: Specializing in LED technology, Dialight is known for its high-performance lighting fixtures that are designed for the most demanding environments.

- Acuity Brands: A leader in the lighting industry, Acuity Brands offers innovative and energy-efficient lighting solutions crafted for a variety of applications.

- Deltalight: With a focus on design and functionality, Deltalight is renowned for its sophisticated and high-quality lighting solutions that enhance any industrial space.

When selecting lighting supplies for your workspace, consider the specific requirements and choose a brand that aligns with your needs.

In the next section, we’ll discuss the installation and maintenance of industrial lighting supplies to ensure optimal performance and longevity.

Installation and Maintenance of Industrial Lighting Supplies

Proper installation and maintenance of industrial lighting supplies are essential to ensure their optimal performance and longevity. Here are some key considerations:

- Professional Installation: For complex lighting systems or fixtures, it is recommended to hire a professional electrician or lighting specialist for installation. They have the expertise and knowledge to ensure the correct wiring, mounting, and positioning of the fixtures. Professional installation also helps avoid potential safety hazards and ensures compliance with electrical codes and regulations.

- Regular Cleaning: Regular cleaning of lighting fixtures is necessary to maintain their performance and prevent dust or debris buildup. For fixtures located in dusty or dirty environments, a more frequent cleaning schedule may be required. Follow the manufacturer’s guidelines for cleaning and use appropriate cleaning materials to avoid damaging the fixtures.

- Replacement of Bulbs or LEDs: Over time, bulbs or LEDs may degrade or fail, impacting the quality of illumination. It is important to replace them promptly to maintain consistent lighting levels. Keep spare bulbs or LEDs on hand to minimize downtime and ensure uninterrupted operation.

- Inspection of Wiring and Connections: Periodically inspect the wiring and connections of your lighting system to ensure they are secure and free from damage. Loose connections or damaged wiring can lead to flickering lights, reduced performance, and safety hazards. If any issues are detected, consult a professional electrician for repairs.

- Upgrading to Newer Technologies: As technology advances, newer lighting technologies may offer improved performance, energy efficiency, and longevity. Consider upgrading your lighting system to take advantage of these advancements. However, ensure compatibility with existing fixtures and consult with a lighting specialist for guidance.

By following these installation and maintenance practices, you can maximize the lifespan and performance of your industrial lighting supplies. In the next section, we’ll discuss safety regulations and standards that apply to industrial lighting.

Safety Regulations and Standards for Industrial Lighting

Industrial lighting must adhere to various safety regulations and standards to ensure the well-being of employees and compliance with legal requirements. Here are some key safety considerations:

- Electrical Safety: Industrial lighting fixtures must meet electrical safety standards to minimize the risk of electrical shock or fire hazards. Ensure that the fixtures are properly grounded, and all electrical connections are secure. Follow local electrical codes and regulations when installing or modifying lighting systems.

- Emergency Lighting Requirements: Emergency lighting systems must comply with specific regulations to ensure the safe evacuation of employees during power outages or emergencies. Exit signs should be prominent and clearly visible, and emergency light units should provide sufficient illumination in emergency situations.

- Lighting Levels: Depending on the nature of the workspace, there may be specific lighting level requirements to ensure safety and productivity. For example, in manufacturing facilities, adequate lighting is necessary to prevent accidents and ensure the accurate inspection of products. Familiarize yourself with relevant lighting level standards and ensure compliance.

- Lighting for Hazardous Locations: Some work environments, such as chemical plants or oil refineries, may have designated hazardous locations. Lighting fixtures used in these areas must be designed and certified for use in such environments. These fixtures are constructed to be explosion-proof and prevent the ignition of flammable substances.

- Maintenance and Inspection: Regular maintenance and inspection of lighting systems are essential to identify any potential safety hazards. Ensure that fixtures are inspected for damage, secure mounting, and proper functioning. Replace any damaged fixtures or components promptly to maintain a safe working environment.

It is crucial to stay updated with the latest safety regulations and standards specific to your industry and location. Consult with lighting specialists or relevant authorities to ensure compliance and the safety of your workspace.

In the next section, we’ll discuss common problems that may occur with industrial lighting and provide troubleshooting tips to resolve them.

Common Problems and Troubleshooting Tips for Industrial Lighting

Industrial lighting systems may encounter various issues over time. Here are some common problems and troubleshooting tips to resolve them:

- Flickering Lights: Flickering lights can be caused by loose connections, aging bulbs or LEDs, or faulty ballasts. Check the connections and tighten them if necessary. Replace any bulbs or LEDs that are flickering consistently. If the issue persists, consult a lighting specialist to inspect the ballasts or wiring.

- Dim or Uneven Lighting: Dim or uneven lighting may occur due to poor bulb or LED quality, incorrect placement of fixtures, or dusty lenses. Replace low-quality bulbs or LEDs with higher-quality options. Adjust the placement of fixtures to ensure even illumination. Clean the lenses regularly to remove dust or debris that may obstruct light output.

- Power Surges or Outages: Power surges or outages can damage lighting fixtures or cause them to malfunction. To protect your fixtures, consider installing surge protectors or uninterruptible power supply (UPS) systems. These devices help regulate electrical flow and provide backup power during outages, minimizing the risk of damage.

- Overheating: Overheating can degrade the performance and lifespan of lighting fixtures. Ensure that the fixtures are not obstructed by objects or debris that may restrict airflow. Clean any dust or dirt accumulated on the fixtures, as it can contribute to overheating. If necessary, consult a lighting specialist to assess the ventilation and cooling requirements of the fixtures.

You can learn more about LED light failures here Beyond The Blink: Solving The Mystery Of LED Light Failures.

If you have any questions about industrial lighting supplies, just feel free to contact us directly. Our lighting experts are ready to help.

Request A Free Quote Now!

Send us a message if you have any questions or request a quote. We will get back to you ASAP!

Leave a Reply

Your email is safe with us.