Every space we need to illuminate is unique. Choosing the right LED lighting color can be tough. It’s one of the most important factors when selecting your lighting fixtures and will make a big difference in how successful your project ends up being.

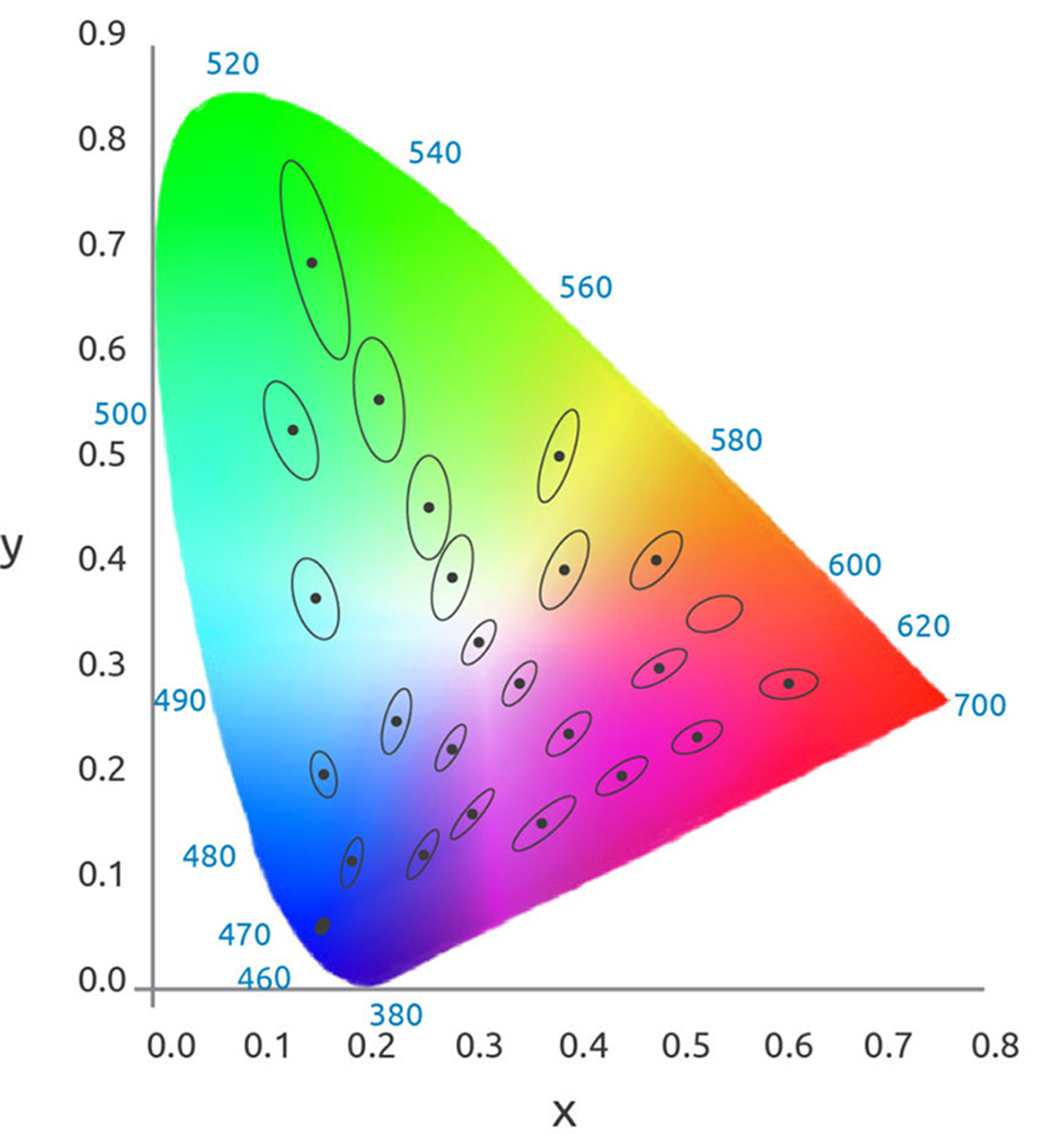

In 1931 the CIE published its famous Chromaticity graph. It meant that every color that could be created by a mixture of red-green-blue could be given a unique number on the graph. Around 1940, David MacAdam ran a series of tests and demonstrated that rather than a single color is indicated by a point on a graph, it could be represented by an ellipse surrounding that point. Within the ellipse, there would be no discernible difference in color from the reference point at its center. The MacAdam ellipse shows how LEDs, belonging to a certain production line, deviate from standard values in their color consistency. And that was the birth of the MacAdam Ellipse.

MacAdam-ellipses-plotted-on-the-CIE-1931-xy-chromaticity-diagram

Until the introduction of the LED, there was very little practical use for the MacAdam ellipse. Light sources were mass-produced and color tolerances were sufficiently controlled that very few people complained about color inconsistencies between two lamps.

However, with the introduction of the LED module, the method of light production changed. The manufacturing process is such that millions of LED chips are produced from an assembly line every day and it’s inevitable that there will be color inconsistencies between individual chips and the modules built from them.

In the early days of LED production, the quality of the product was determined by the accuracy of the binning process of chips. This was the way that LEDs were separated into separate bins according to LED lighting color output. It was an expensive and time-consuming process. Improvements in LED module design have brought the Macadam Ellipse to the forefront of the color checking process.

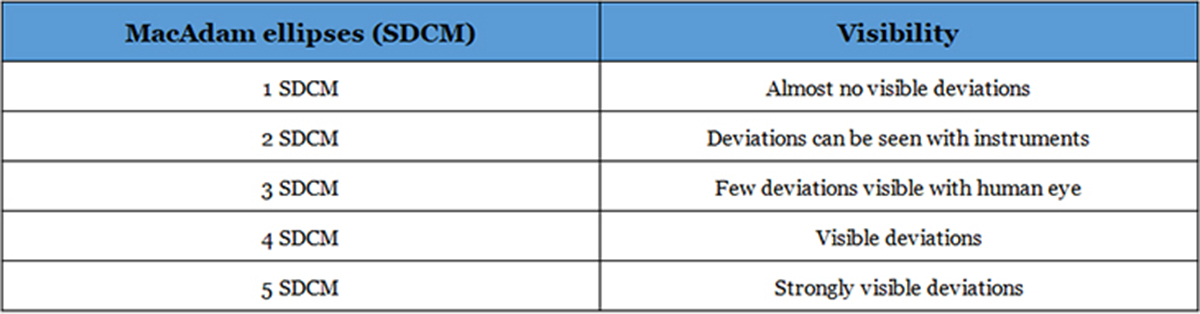

A perfect LED module assembly line will produce batches of modules operating within a MacAdam Ellipse. There will be no discernible difference between any of the module outputs. LED modules produced at this level are used where color performance and accuracy between fixtures are vitally important. Typically, good LED modules are produced within a two to three MacAdam ellipse range, there will be a visual difference if you look for it, but it is minor and generally considered to be acceptable in commercial usage. The following table provides an overview:

MacAdam Ellipse

Tighter control of the LED lighting color is desirable, but this must be balanced with the associated costs of doing so. The production of LEDs has improved over time, and manufacturers are able to control the resulting color output today. But there are still color variations based on certain manufacturing tolerances. Production of LEDs is sorted (binned) by proximity to the center point, resulting in varying quantities in each bin. If an LED manufacturer has good control over the various inputs, the majority of production will fall within the tighter ellipses, but there will still be LEDs that fall into the larger ellipses. Pricing of these LEDs follows the law of supply and demand, so the smaller, more desirable ellipses are more costly. High-quality products may have a higher price, but the greater consistency in color temperature and brightness make them a worthwhile investment.

If you have any questions about choosing a good LED lighting fixture, welcome to contact us directly.

Request A Free Quote Now!

Send us a message if you have any questions or request a quote. We will get back to you ASAP!