I understand your struggle with high energy costs and poor lighting performance. Outdated lighting increases expenses and lowers employee safety and productivity. The solution is understanding clearly whether LED or HID lighting fits your needs best.

Choosing between LED and HID lighting for your industrial or commercial project comes down to efficiency, lifespan, costs, and environmental impact. LEDs offer higher efficiency, consuming significantly less energy and lasting much longer than HID lamps. Though the initial investment in LED lighting can be higher, it quickly pays for itself through energy savings and reduced maintenance and replacement costs. HID lights have lower upfront costs, but their shorter lifespan, higher maintenance requirements, and declining performance lead to increased expenses over time. Environmentally, LEDs contain no harmful substances, while HID lamps often use hazardous materials like mercury.

So, let’s dive deeper and uncover how each lighting solution measures up.

Table of Contents

Energy Consumption: LED Lighting Efficiency vs HID Lamps

When I initially entered the lighting business, HID lamps were appealing due to their bright output. However, it quickly became evident that they squander significant energy. LEDs revolutionized the industry by consuming about 50-75% less energy compared to traditional HID lamps, which translates into substantial savings on utility bills. Factories and warehouses notably benefit by reducing energy costs, making room for reinvestment in other areas.

While HID lamps might seem cheaper up front, their operational energy costs accumulate quickly, diminishing any initial savings. In contrast, energy-efficient industrial LED lighting offers considerable financial advantages over the long term due to lower energy consumption and reduced maintenance needs. Investing in LED lighting is not only cost-effective but also aligns with sustainable practices.

Lifespan Comparison: How Long Each Option Lasts

When comparing the lifespan of HID lighting to LED fixtures, the difference is quite significant. HID lighting typically lasts between 10,000 to 25,000 hours. This might seem substantial at first, but LEDs often outshine them with a lifespan ranging from 50,000 to 100,000 hours or more. For instance, some LED modules are reported to maintain over 90% of their initial luminous flux even after 50,000 hours. In certain conditions, LED lights can exceed 100,000 hours, depending on factors such as temperature and design.

The extended lifespan of LED fixtures means fewer disruptions for maintenance and lower costs, as you won’t need to replace bulbs frequently. HID bulbs might burn out faster and could fail unexpectedly, especially in environments that rely heavily on stable lighting. In commercial areas, shifting from HID to LED not only enhances reliability but also significantly reduces labor and maintenance expenses.

Evaluating Maintenance Costs for HID vs LED Lighting

LED lighting maintenance costs are substantially lower compared to HID solutions. Since LEDs last far longer, fewer replacements are needed. Plus, HID lights require costly regular ballast replacements, while LEDs don’t. I have seen first-hand how clients reduced their downtime and cut repair expenses after transitioning to quality LED fixtures. Maintenance saved equates to productivity gained. These extra savings quickly add up, making LED lighting a wise investment for commercial lighting solutions.

Brightness and Performance: Which Produces Better Results?

LED lighting consistently outperforms HID systems in both brightness and overall performance. HID lamps typically suffer from a notable drop in brightness as they age, leading to inconsistent illumination levels. This deterioration can affect productivity and safety, particularly in performance-driven environments, where consistent lighting is crucial.

LEDs, however, maintain their luminous intensity throughout their lifespan, providing steady and uniform lighting and ensuring that workers operate under reliable conditions. This consistency makes LEDs the preferred choice for applications that demand high performance and sustained brightness, such as sports and competitive environments. In essence, the reliable output and reduced decline in performance make LEDs a superior option for ensuring optimal results.

Environmental Impact and Disposal Issues

Okay, let’s talk HID lighting and the environment. It’s getting pretty clear that these bulbs come with baggage. We’re not talking about a suitcase or a duffel bag; we’re talking mercury. Yes, the kind of stuff that’s, let’s say, not great for humans or the ecosystems we depend on for survival. Now, disposing of these bulbs becomes a whole operation. We’re talking special recycling processes that make you scratch your head and wonder why anyone is still using them.

Enter LEDs—the heroes we deserve. They don’t carry those toxic credentials. Disposal is easier, safer, and doesn’t involve elaborate rituals or special handlers. When you switch to LEDs, you’re not just making a lighting decision; you’re making an environmental statement. It’s a smart, responsible move for businesses wanting to flaunt their eco-friendly badges. The cherry on top? Customer trust. People want to support brands that walk the sustainability walk and don’t just talk the talk. Transitioning to LEDs isn’t just about cutting down on energy costs, although that’s a nice perk. It’s about stepping up to a greener future, cultivating a reputation that says, “We care about our planet and your trust.”

Initial Investment and LED Lighting ROI Analysis

Alright, let’s dive into the dollars and sense of LED lighting. At first glance, the upfront price tag of LED fixtures might make you do a double take. It’s understandable—everyone likes a bargain. But here’s the twist: once you peel back the layers and dig into LED lighting ROI analysis, the picture changes dramatically.

Sure, HID lamps might seem like a steal initially, but they’re the classic case of short-term gain, long-term pain. Energy inefficiency kicks in, and those pesky replacements start stacking up like bills after a holiday spending spree. LEDs, on the other hand, start showing their smarts pretty quickly. They offer significant energy savings, which means fewer dollars pouring out for the same brightness. Maintenance costs take a nosedive, as well—no more frequent bulb changes or elaborate upkeep routines.

Almost without fail, clients are reaping the rewards with a favorable ROI in just two to three years. That’s a turnaround time even the most discerning business minds find hard to resist. It’s like owning a golden goose—steady returns, solid savings, and an easy conscience knowing you’re investing in something sustainable. Smart companies see the writing on the wall and find it tough to ignore these compelling numbers. LEDs are where savvy meets sustainability, and it’s a pairing that’s hard to beat.

Safety and Workplace Productivity

Let’s get real about safety and productivity in industrial settings—it’s crucial. Lighting isn’t just about brightening a space; it’s about ensuring that every corner is illuminated safely and effectively. When I look at HID lamps, the issue becomes clear. Flickering and inconsistent lighting lead to visibility problems, turning a well-oiled machine into a field of hazards, increasing accidents, and taking a toll on productivity.

Enter LEDs, the champions of consistent, flicker-free lighting. They’re not just about brightness; they’re about clarity and dependability. Employees can perform their tasks with precision, reducing the risk of accidents and creating a secure work environment. This reliable lighting boosts productivity—people work better when they’re not squinting into shadows or battling glare. Plus, consistent lighting means less downtime and fewer productivity drops due to mishaps.

By switching to LEDs, you’re not just upgrading your fixtures; you’re investing in your workforce. You’re creating an atmosphere that prioritizes safety and efficiency, ensuring everyone can focus on their tasks with confidence. It’s a move that protects your people and your bottom line, creating a workplace where everyone thrives.

Durability: Which Lighting Holds Up Better?

Industrial conditions can be tough on lighting systems. Traditional HID lights are fragile and can break under rough handling or demanding environments. In contrast, modern LED fixtures are highly durable, resistant to impacts, vibrations, and harsh conditions—even damp or humid industrial areas become simpler to manage. Having installed LEDs for numerous factory clients, I know the difference durability makes. Employees spend less time dealing with broken lights and you enjoy reduced replacement costs.

Instant-On Lighting and Operational Convenience

HID lamps require a warm-up period, sometimes several minutes. This delay wastes valuable time. LEDs are instant-on, providing immediate full brightness at the flick of a switch. Instant illumination increases operational efficiency, saving precious minutes in busy commercial and industrial environments. Employees can immediately begin work under proper lighting without waiting for lights to fully brighten. Operational convenience further demonstrates LED’s superiority.

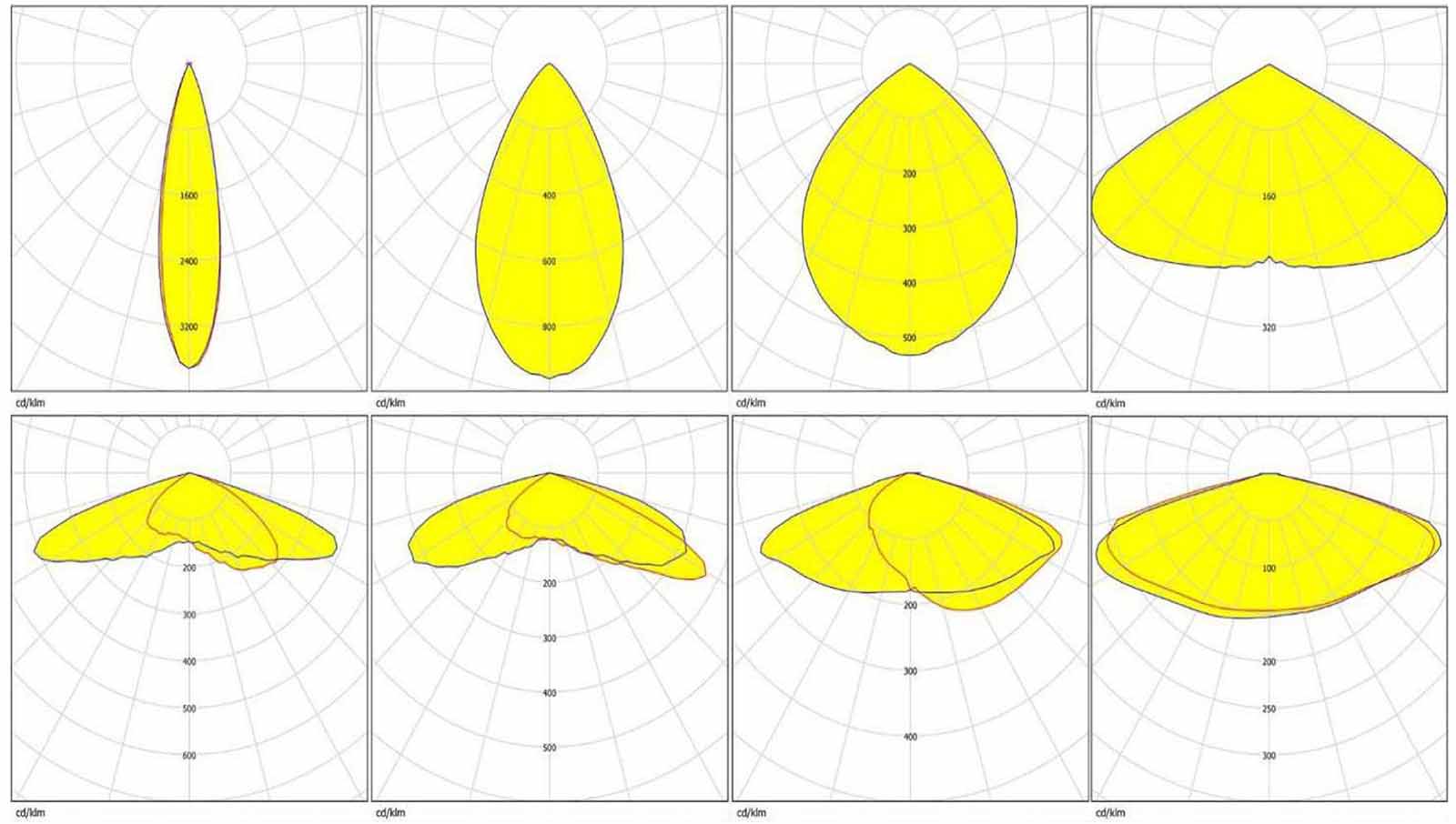

Light Distribution and Beam Control

HID lamps scatter light in multiple directions, leading to uneven illumination and wasted energy. This lack of precision affects overall efficiency and can contribute to light pollution. LEDs, on the other hand, offer precise beam control, allowing for perfectly directed illumination where needed. This targeted approach reduces energy waste and enhances visual quality, providing superior lighting tailored to specific applications.

With customizable optics available, achieving optimum illumination is straightforward. Careful control means that only desired areas are lit, minimizing distractions and enhancing the environment. This technology allows for advanced adjustments and customization, ensuring that every space gets exactly the amount of light required without any leftovers spilling into unintended areas.

Switching to LEDs not only addresses energy efficiency but also provides a clear advantage in terms of maintaining quality lighting while reducing unnecessary light dispersion and pollution.

Color Rendering and Light Quality

When accurate color vision matters, LEDs strongly outperform HID lamps. LEDs provide better color rendering index (CRI), making colors appear true and natural. HID lamps often distort colors, increasing error likelihood and potentially impacting quality control. To facilitate precise tasks, especially inspections, switching to high-quality LEDs ensures accurate visual perception.

Conclusion

LED lights hold advantages over HID across efficiency, lifetime cost, performance, and environmental impact. For industrial and commercial applications, LED lighting solutions clearly present more significant benefits—from substantial energy savings to minimal maintenance and unparalleled safety enhancement. LEDs offer practical, long-term investments yielding impressive returns and productivity boosts. Companies purchasing industrial LED products from leading suppliers, such as Logos Lighting, experience remarkable ROI and satisfaction. If you need advice on selecting proper LED lights or have questions, don’t hesitate—just reach out to us directly. It’ll be my pleasure helping you successfully upgrade your facilities today!

Request A Free Quote Now!

Send us a message if you have any questions or request a quote. We will get back to you ASAP!