It is often heard that the short life of LED lamps is mainly due to the short life of the power supply, and the short life of the power supply is due to the short life of the electrolytic capacitor. These claims could make sense. As the market is flooded with a large number of short-lived and inferior electrolytic capacitors, coupled with competing prices, some LED lighting manufacturers use these inferior short-life electrolytic capacitors regardless of quality.

So what exactly is the actual situation?

Table of Contents

1. The life of the electrolytic capacitor depends on the ambient temperature when it works

How is the life of electrolytic capacitors defined? Definitely in hours. However, if the life index of an electrolytic capacitor is 1,000 hours, it does not mean that the electrolytic capacitor fails after one thousand hours, but only that the capacity of the electrolytic capacitor is reduced by half after 1,000 hours. If it is 20uF, and now it is only 10uF.

Besides, when we talk about the life index of electrolytic capacitors, life under the working temperature must be stated. And it is usually specified as the life at an ambient temperature of 105 °C.

This is because the electrolytic capacitors we usually use are electrolytic capacitors which using liquid electrolyte today. So of course, if the electrolyte is dry, the capacitance will certainly be gone. The higher the temperature, the easier the electrolyte will evaporate. Therefore, the life index of the electrolytic capacitor must indicate the life under what ambient temperature.

So all electrolytic capacitors are currently marked at 105 °C. For example, the most common electrolytic capacitor has a life of only 1,000 hours at 105 °C. But if you think that the life of all electrolytic capacitors is only 1,000 hours. That would be wrong.

To put it simply, if the ambient temperature is above 105 °C, its life will be less than 1,000 hours, and if the ambient temperature is below 105 °C, its life will be more than 1,000 hours. Is there a general quantitative relationship between life and temperature? Of course.

One of the simplest and easiest way to calculate the relationships is that for every 10-degree increase in ambient temperature, the lifespan is reduced by half; Conversely, for every 10-degree decrease in ambient temperature, the lifespan is doubled. Of course, this is just a simple estimate, but it is quite accurate.

As the electrolytic capacitors used for LED drivers are placed inside the housing of the LED lamps, we only need to know the temperature inside the LED lighting fixtures to know the working life of the electrolytic capacitor.

2. What is the ambient temperature in the LED lamps?

Because in many LED lamps the LED and electrolytic capacitors are placed in the same housing, the environmental temperature of the two is the same. The ambient temperature is mainly determined by the heating and cooling balance of the LED and the power supply. And each LED lamp’s heating and cooling situation is different, so how can we know the ambient temperature in it?

In fact, this problem can be calculated in reverse, that is, as a well-designed LED lamp, the allowable internal ambient temperature shall be constant. This is because the junction temperature of the LED chip is the main factor that determines the light decay (lifetime) of the LED chip. Of course, the junction temperature of the LED is also related to its ambient temperature, so as long as the allowed junction temperature of the LED is known, the internal temperature of the LED lamp can be calculated.

But there are at least three thermal resistances, namely the thermal resistance θjc from the junction of the LED chip to the case, and the thermal resistance of the LED case to the surface of the aluminum substrate. In fact, it passes through solder, copper foil, and insulation to the aluminum plate, while among them the most important is the thermal resistance of the insulation layer, collectively referred to as θlv, and the third is the thermal resistance θla from the aluminum plate to the air in the bubble.

Let’s take the 3014 type LED for example. Its thermal resistance θjc is 90 °C / W. Because its power is only 0.1W, the temperature difference between the inside and the outside is 9 °C. The thermal resistance of the aluminum substrate is 1 °C / W. For a 10W LED lamp since all 10W LEDs are mounted on the same aluminum substrate, the total temperature difference is 10 °C, and the total temperature difference is 19 °C. The final θla is difficult to estimate because it is related to the circulation of air. When the internal air is not flowing, the temperature difference is only about 1 °C, so the total is 20 °C. That is, the LED junction temperature is equal to the ambient temperature plus 20 °C.

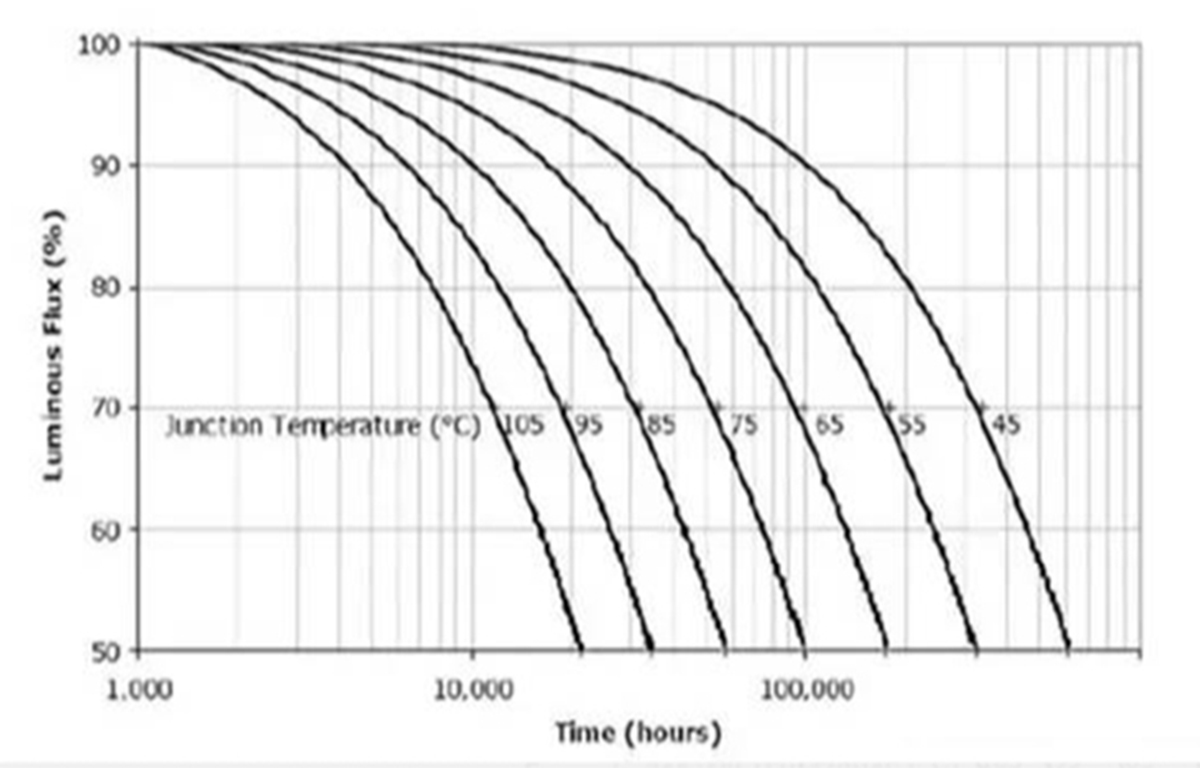

So can the ambient temperature inside the lamp allow 105 degrees? Just take a look at one of the pictures below. That is the relationship between Cree’s LED chip junction temperature and light attenuation.

LED Chip Junction Temperature and Life Decay

If the ambient temperature is 105 °C, then it must add at least 20 °C to the junction temperature, so the junction temperature is about 125 °C. You can’t find it on this curve, you can only roughly estimate its life is only 4,000 hours. This is absolutely unacceptable! In other words, the ambient temperature in the LED lamp must be much lower than 105 °C!

We can see in turn what the ambient temperature should be based on the required LED life. Suppose we require the life of the LED to be 100,000 hours, then its junction temperature can only be lower than 65 °C, so the ambient temperature must be lower than 45 °C. That is, the working ambient temperature of the electrolytic capacitor must be lower than 45 °C.

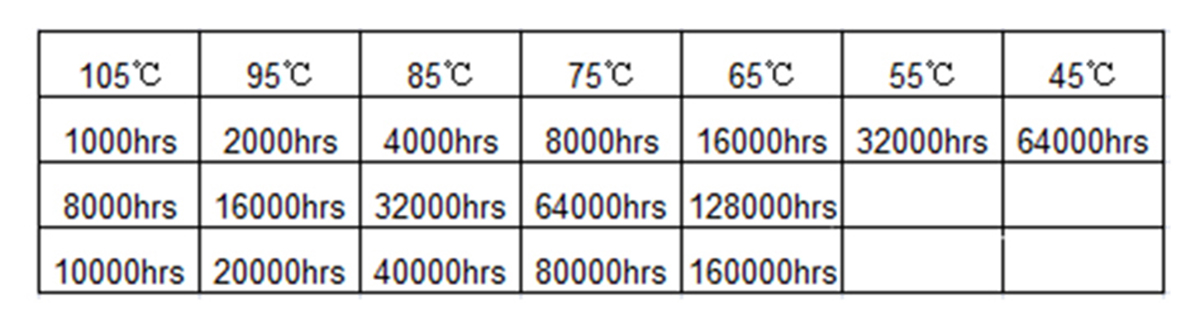

3. The actual life of electrolytic capacitors with various lifespans at an ambient temperature of 45 °C

Now that we know the working ambient temperature of electrolytic capacitors in actual LED lamps, we can easily calculate its actual life. We have listed the actual life of several commonly used electrolytic capacitors in the table below.

Electrolytic Capacitors Life

It can be seen from the table that even the most common electrolytic capacitors with a life of 1,000 hours can reach a life of 64,000 hours at an ambient temperature of 45 °C. For ordinary LED lamps labeled 50,000 hours, that is enough.

4. Methods to extend the life of electrolytic capacitors

4.1 Extend its life by design

In fact, to extend the life of electrolytic capacitors, the method is very simple, because the end of its life is mainly due to the evaporation of the liquid electrolyte. If you improve its seal and prevent it from evaporating, its life will naturally extend.

Besides, by adopting a phenolic plastic cover with an electrode wrapped around the entire body and a double specially-made gasket tightly engaged with the aluminum shell, the loss of the electrolyte can also be greatly reduced.

4.2 Prolong its life from use

Reducing its ripple current can also extend its service life. If the ripple current is too large, it can be reduced by using two capacitors in parallel.

4.3 Choosing a suitable capacitor to extend its life

In the selection of electrolytic capacitors, in addition to the use of brand-name electrolytic capacitors to ensure quality, there must be a margin in voltage and capacity. For example, the DC voltage of 220V after bridge rectification will be as high as 300V, but at least 450V electrolytic capacitors should be used when selecting electrolytic capacitors. If it is calculated that 10uF is needed, it is better to choose 20uF. These measures can also extend the life of electrolytic capacitors. Because the capacitor’s equivalent resistance and ripple current will make its internal temperature higher than the ambient temperature, it is necessary to leave some leeway.

5. Protection of electrolytic capacitors

Sometimes even if a long-life electrolytic capacitor is used, it is often found that the electrolytic capacitor is broken. What is the reason for this?

In fact, if you think that the quality of electrolytic capacitors is not enough, then it really makes the electrolytic capacitors suffer injustice! In fact, at this time, the electrolytic capacitor is not the perpetrator, but the victim. Why do you say this way?

Because we know that on the AC grid of the city’s electricity, lightning surges often cause momentary high-voltage surges. Although large lightning protection measures have been implemented for lightning strikes on large power grids, it is still inevitable that leakage will appear at home.

For LED lighting fixtures that are powered by the city electricity, you must add anti-surge measures to the mains input terminals in the power supply of the LED lamps, including fuses and over-voltage protection resistors, to protect the following components, otherwise, any a branded long-life electrolytic capacitors will be punctured by the surge voltage.

If you have any questions or need help choosing a good LED lighting fixture, please contact us directly. Our lighting experts will help you get the best lighting that you need.

Request A Free Quote Now!

Send us a message if you have any questions or request a quote. We will get back to you ASAP!