Are you feeling overwhelmed trying to understand UVA, UVB, and UVC lighting types? Choosing incorrectly can hurt your business, risking worker safety and efficiency. Don’t worry; in this guide, I’ll clearly explain it all.

Understanding ultraviolet lighting differences can seem confusing, but it’s actually pretty simple once broken down. UVA, UVB, and UVC differ mostly in their wavelength and usage. UVA (315-400 nm wavelength) is closest to visible light, commonly used to cure adhesives, spot printing, and inspection purposes. UVB (280-315 nm) has shorter wavelengths and is linked mainly to medical treatments, plant growth enhancement, and reptile lighting applications. UVC (100-280 nm) has the shortest wavelength, and it’s the type that quickly kills germs. For this reason, UVC sanitation systems are commonly used in water treatment, sterilization of air, surfaces, and industrial equipment to ensure effective safety and germ-free environments.

Let’s dive deeper so you can easily determine what’s best for your industrial or commercial lighting needs.

Table of Contents

What Exactly is Ultraviolet Light, and Where Does It Fall in the Spectrum?

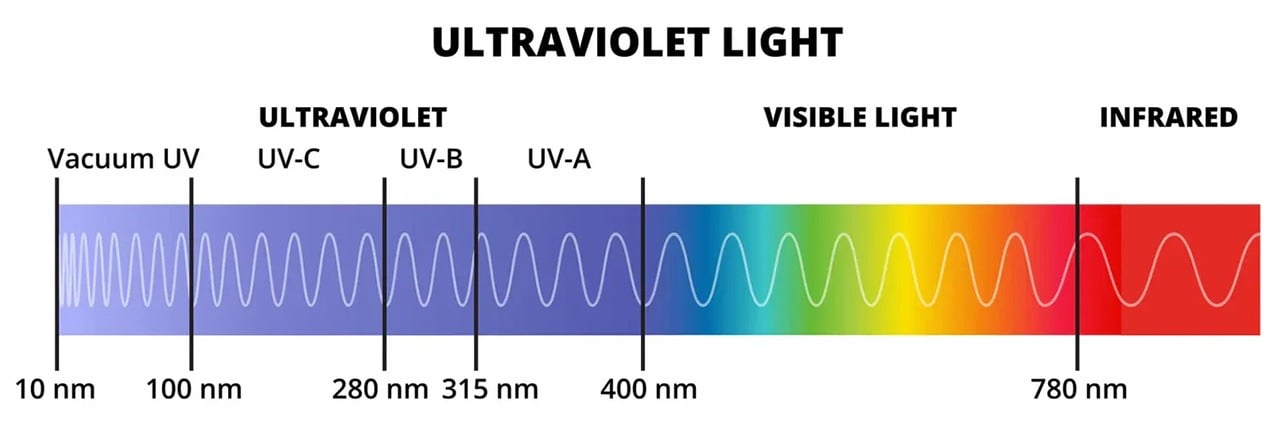

Ultraviolet (UV) light is a type of invisible radiation that lies in the electromagnetic spectrum between visible light and X-rays. It is emitted both naturally from the sun and artificially from sources like UV lamps. UV radiation is categorized into three types based on wavelength: UVA, UVB, and UVC. These categories collectively form the ultraviolet wavelength spectrum.

- UVA: Longest wavelength, least harmful, and used in applications such as UV curing.

- UVB: Medium wavelength, responsible for skin tanning and burning.

- UVC: Shortest wavelength, most energetic, and used for sterilization.

Understanding these wavelengths is crucial for industrial and commercial applications, ensuring that UV light is used safely and effectively to meet specific requirements.

UV Light

UVA Lighting: What’s It Used For in Industrial and Commercial Applications?

UVA radiation ranges from 315 to 400 nanometers and is the closest type to visible light. Industrially, UVA finds use mainly in curing adhesives and polymers. If you have products that need quick drying and strong bonding, UVA is your friend. Industries such as printing, packaging, and automotive paint curing rely heavily on UVA lights. Commercially, it’s also popular for black-light displays, security verification (like banknotes), and insect-attracting bug zappers. Although UVA poses the lowest health hazards of all UV types, care and adherence to UV exposure safety guidelines remain necessary when using them regularly.

UVB Lighting: How Does It Differ from UVA, and Where’s It Typically Applied?

UVB radiation has slightly shorter wavelengths between 280 and 315 nanometers. Its shorter wavelengths mean higher energy, making it more powerful than UVA for certain specialized uses. You’ll mainly see UVB lights employed in medical treatments, horticulture, plant growth, and specialized animal habitats like reptile enclosures. For plants, UVB provides stimulation that enhances growth and increases vitamin production. While UVB exposure is necessary in controlled applications, such as reptile tank lighting, it carries significant health risks to human skin and eyes. Protecting employees and users from overexposure through responsible safety procedures should be prioritized.

UVC Lighting: Why Is It So Effective at Killing Germs, and How’s It Applied in Industries?

UVC radiation spans wavelengths from 100 to 280 nanometers, giving it the shortest yet most potent ultraviolet wavelength. It holds the highest germ-killing potential, making it particularly invaluable in UV sterilization industrial applications. Specifically designed UVC sanitation systems deliver rapid destruction of bacteria, viruses, molds, and pathogens by breaking down their DNA structure. Industries such as healthcare, food processing, pharmaceutical manufacturing, and water treatment employ UVC lighting to ensure strict sanitary conditions. Its effectiveness dramatically reduces contamination and ensures cleaner environments. However, because of its powerful germicidal properties, strict safety measures must be implemented during use to prevent potential harm to workers.

Comparing Health Risks: UVA vs UVB vs UVC—What’s the Safe Way to Handle UV Lighting?

The health risks of ultraviolet radiation depend heavily on wavelength exposure. UVA lighting, having lower energy, presents minimal health risks. However, prolonged exposure can still contribute to eye issues over time. UVB has a higher risk, often causing skin damage, sunburn, and potentially skin cancers after repeated exposure. UVC delivers the highest health risk among the three due to its germicidal characteristics. Short but powerful wavelengths can damage skin and eyes very quickly. Safe handling includes using protective eyewear, specialized clothing, limiting exposure, and establishing proper safety protocols in your work environment. Adopting comprehensive UV exposure safety guidelines can significantly reduce these risks.

How to Choose the Right UV Lighting Fixtures and Lamps for Your Needs?

Selecting the right UV lighting fixtures involves assessing your specific application and safety requirements. Here’s a guide to help you choose:

- Define Your Goals: Identify your industry-specific needs. Do you need UV for curing adhesives, bonding, or sterilization purposes? Understanding the purpose will guide your choice between UVA and UVC lamps.

- Select Correct Wavelength: Choose wavelength-specific lamps—UVA for applications like adhesive curing and UVC for sterilization. The wavelength determines the lamp’s energy and effectiveness.

- Quality and Certifications: Ensure that the UV fixtures you choose have reliable quality and safety certifications. Opt for well-known brands like Osram and Philips, which provide safety assurance and longer lifespan.

- Customization Options: Use companies like Logos Lighting that offer tailored solutions to meet your exact needs, ensuring the UV lighting fixtures are perfectly suited to your requirements.

By carefully considering these factors, you can select UV lighting fixtures and lamps that ensure effectiveness, safety, and reliability for your specific applications.

Practical Examples in Industry for UVC Germicidal Lighting Usage

Many industries successfully use UVC germicidal lighting for better safety and sanitation. Hospitals use it to disinfect surgical instruments and ward environments, resulting in fewer healthcare-acquired infections. Food manufacturers reduce bacterial contaminations significantly through UV sterilization, greatly improving product shelf-life and quality. Pharmaceutical companies employ carefully controlled UVC systems to achieve stringent cleanliness and prevent contamination or production losses. Wastewater treatment plants rely on UVC radiation to effectively sanitize water streams. These real-world UV lighting commercial use cases highlight practical benefits and effectiveness, ensuring cleaner, healthier facilities.

Common Mistakes Businesses Make When Implementing UV Lighting in Their Premises

- Misunderstanding Wavelength Differences: Businesses often select UV lamps based solely on price rather than understanding the specific wavelength differences and their applications. Choosing the wrong type of lamp can result in ineffective solutions or safety issues.

- Ignoring Safety Precautions: Safety is crucial when implementing UV lighting. Exposing employees to excessive UV radiation without proper precautions can lead to health risks. Ensuring reliable quality and safety certifications is essential to prevent such issues.

- Improper Positioning and Coverage: Overlooking the correct positioning and placement of UV fixtures can significantly reduce effectiveness. Proper installation is vital to ensure adequate coverage and maximize the benefits of UV lighting.

- Lack of Professional Consultation: Many businesses fail to consult lighting professionals, leading to costly errors. Engaging experts can provide accurate advice tailored to specific industrial or commercial environments, ensuring safe and effective implementation.

By educating themselves and consulting with professionals, businesses can avoid these common pitfalls and ensure successful UV lighting installations.

How Will Ultraviolet Lighting Technologies Evolve in the Future?

Looking forward, ultraviolet lighting technologies seem primed for improvements in effectiveness, energy efficiency, and safer applications. Innovations in LED technology already provide more precise wavelength control, higher durability, longer lamp life, and lower energy use. Increases in automated controls and intelligent lighting solutions mean safer workplaces through more precise exposure management. Future advancements might include easily customized UV light solutions tailored specifically to industry applications, increased data-driven management integrations, and safer built-in UV exposure monitoring. These enhancements will ensure prolonged performance with significantly reduced operational risks.

Conclusions

To wrap it up, understanding UVA, UVB, and UVC helps you make better-informed decisions for industrial or commercial environments. Knowing specific UV radiation wavelength differences simplifies selecting fixtures and lamps necessary for your exact needs. While highly beneficial, UV radiation requires thoughtful handling, following guidelines carefully and prioritizing accurate fixture selection, ensuring safety and effectiveness. By educating yourself and consulting reliable sources, you’ll confidently and successfully harness UV technology advantages safely in your business.

Request A Free Quote Now!

Send us a message if you have any questions or request a quote. We will get back to you ASAP!